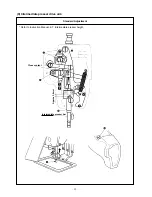

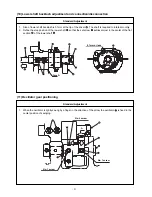

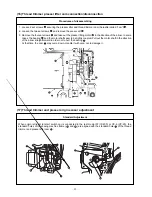

1. Turn ON the power supply and set the height of the intermediate

presser

to 0mm. Turn OFF the power supply in the state that the

intermediate presser

has been lowered.

2. Loosen the intermediate presser stroke adjusting screw

.

3. Turn the pulley and move the needle bar to the lower dead point.

When the intermediate presser

is lifted and the intermediate presser

stroke adjusting screw

is moved to the right or left, confirm that

the intermediate presser adjusting arm

is positioned not to move

vertically and that the intermediate presser positioning link

keeps

a close contact with the arm. In this state, tighten the setscrew

of

the intermediate presser drive arm.

(The clearance is approximately 3.6mm between the intermediate

presser needle bar connection and the intermediate presser bar metal

.)

4. After the setscrew

has been tightened, confirm that there is no

backlash in the intermediate presser adjusting arm

in the forward

and backward directions.

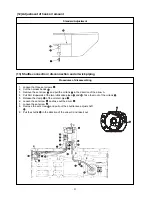

5. Finally, make adjustments of the intermediate presser stroke.

(Refer to Instruction Manual

III

. MAINTENANCE OF SAWING MA-

CHINE, 1-4. Adjusting the vertical stroke of the intermediate presser.)

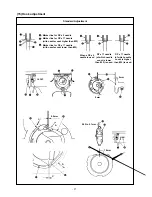

o If there is no clearance, there will

be interference between the

intermediate presser bar metal

and the intermediate presser

needle bar connection during

sewing machine operation, and

this will generate abnormal sound

as a result.

o If there is too much clearance,

there will be interference between

the intermediate presser adjust-

ing arm

and the arm during

sewing machine operation, thus

generating abnormal sound as a

result.

o If there is too much or too less

clearance, the lower dead-point

height of the intermediate presser

may be changed as a result of

intermediate presser stroke ad-

justments.

– 20 –

Adjustment Procedures

Results of Improper Adjustment