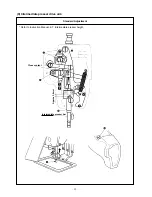

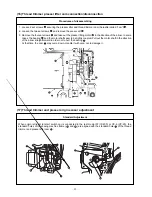

1. Lower shaft backlash

1) Loosen the two set screws

.

2) Turn the lower shaft rear metal

in the direction of the arrow and adjust

the backlash, keeping the metal to contact closely with Face A.

Size of backlash is 0.1mm at the tip of the driver

. The shaft is

required to rotate smoothly.

3) Tighten the two set screws

.

(Caution) When eliminate the backlash, the direction of rotation

should always be kept in the direction of the arrow.

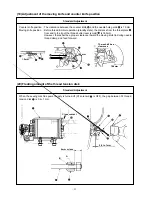

2. Lower shaft connection/disconnection

1) Loosen the two set screws

.

2) The lower shaft

can be taken out if it is pulled in the direction

C

of the arrow.

3) When mounting the lower shaft

, insert it in the lower shaft rear

metal

and the lower shaft gear

. Apply one of the set screws

to the flat section

of the lower shaft

and tighten it approxi-

mately in the center. Tighten the remaining set screw

.

* Connection and disconnection of the lower shaft

become easy if

the above-mentioned backlash has been relieved in advance. In this

case, backlash adjustment must be done after the lower shaft

has

been installed.

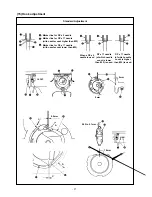

o If the backlash is excessive, the

hook noise will be increased.

o If backlash is too small, the lower

shaft gear

or the oscillator

will give rise to frictional wear. In

addition, this can be a cause of

crank rod lock-up.

o If the front or rear position of the

lower shaft rear metal

is dis-

placed at the time of backlash

adjustment, this can also be a

cause of the lock-up of oscillator

or the crank rod.

– 22 –

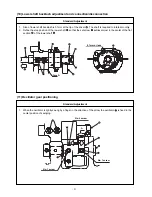

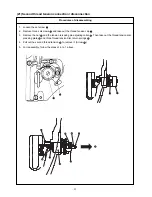

1. Loosen the two set screws

and increase the backlash of the lower

shaft gear

.

(Caution) 1. If the lower shaft gear

has insufficient backlash,

the oscillator

does not swing correctly. In such a

case, refer to [(10) Lower shaft backlash adjustment

and connection/disconnection] and provide a suffi-

cient backlash.

2. The three set screws

should have been loosened in advance. In

this case, the second screw of the set screws

should be loosened

first. Then, the first one can be loosened.

3. Lightly swing the whole body of the oscillator

with a finger in the

direction of the arrow. Decide the positioning of the oscillator

so

that it stays in the center of swinging.

4. Loosen the three set screws

and then fix them so that the oscilla-

tor

is not displaced from the center of swinging.

(Tighten the first screw first so that it comes in contact flatly with the

oscillator shaft

. Then, tighten the second one.)

5. Make backlash adjustment for the lower shaft gear

, according to

[(10) Lower shaft backlash adjustment and connection/ disconnec-

tion].

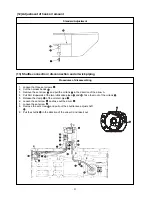

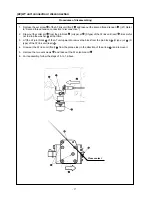

(Cautions) 1. In the case of disassembly and adjustment, grease-

up treatment is always needed for the specified

places (2 positions) and the gear area A of the oscil-

lator

.

2. When the crank rod (under-cam) is removed, actions

for under-cam positioning must be taken, without fail.

Refer to [(3) Crank rod connection/ disconnection].

o If the position for fixing the

oscillator

is inadequate, this

can also be a cause of the

frictional wear or lock-up of the

oscillator pin, crank rod lid, under-

cam, and the crank rod.

Adjustment Procedures

Results of Improper Adjustment

Adjustment Procedures

Results of Improper Adjustment