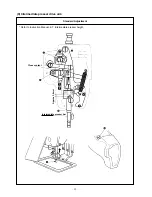

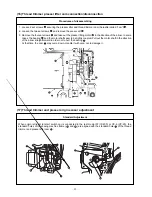

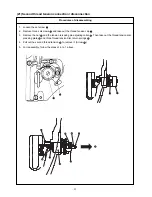

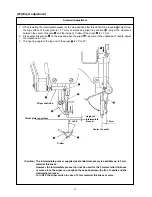

1. Apply a proper amount of grease (Juki Grease A) to the grooved cam block of the cam

, the peripheral cam

block, and the rollers of the presser bar lifter link

and the thread trimmer link

. Refer to “10.-(4) Parts to

which grease • lock-tight is applied o TENSION RELEASE & THREAD TRIMMER MECHANISM

COMPONENTS.”

2. While the cam

is being inserted in the shaft of the presser lifting motor

, mount the assembly on the

sewing machine frame and tighten the four set screws

. The insertion of the cam should be done gently in

order not to hurt the bearing

.

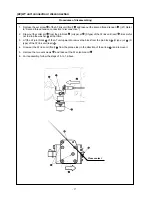

3. Clearance B toward the presser bar lifter link

and Clearance A toward the thread trimmer link

should be

equally distributed. For this purpose, adjust the position of the cam

and fix it with the use of the two set

screws

. (Apply the screws to the flat section at both ends of the shaft.)

* If it is difficult to examine Clearance B, Clearance A should be adjusted to 0.5mm ~ 0.7mm during assembly.

4. Mount the sensor slit

with the two set screws

so that the end plane of the motor shaft can approxi-

mately coincide with that of the sensor slit

. (Join the flat section for installation.)

* Confirm that the slit plate of the sensor slit

does not interfere with the presser bar lifter sensor.

5. Refer to “3.-(17) Thread trimmer and presser origin sensor adjustment” and make sensor adjustments.

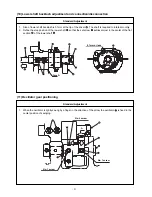

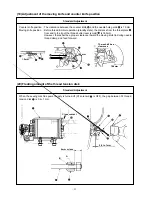

1. Start the test mode I07 (IP-400) or CP-6 (CP-20).

2. Tread on the pedal for the retrieval of the thread trimmer and presser

bar lifter (cam) origin.

3. Make sure that the standard holes (

A

and

B

) of the thread trimming

motor stand are aligned with the standard hole

C

of the thread trim-

mer and presser lifter cam

using a bar

.

4. If the standard hole

C

of the thread trimmer and presser lifter cam

is too high (

E

direction), loosen the set screw

and move the sen-

sor mounting plate

upward (

E

direction) and secure it.

If the standard hole

C

of the thread trimmer and presser lifter cam

is too low (

D

direction), loosen the set screw

and move the

sensor mounting plate

downward (

D

direction) and secure it.

After securing the sensor mounting plate

, conduct origin retrieval

by pressing the pedal to make sure that the standard holes are aligned.

5. Repeat the above steps 2 to 4 until the coincidence is confirmed.

(Caution) Tighten the set screw

after confirming that there is no

interference between the sensor slit plate

and the sen-

sor.

o If the standard holes are not

aligned, the thread trimming

timing error occurs and defective

thread trimming and unthreading

at the beginning of sewing may

be caused.

– 30 –

Adjustment Procedures

Results of Improper Adjustment

Procedures of assembling