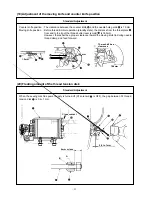

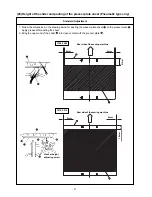

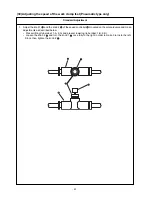

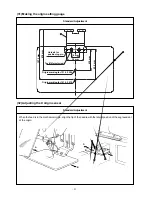

1. Move the race table

to the left end (in the direction of the arrow).

2. Tighten the adjusting screw

and fix the nut

so that the load

point makes a warp of 4mm when a load of 7.84N (800gf) measured

by a spring balance is applied to the timing belt

.

3. Tighten the set screw

and check the amount of deflection again.

– 44 –

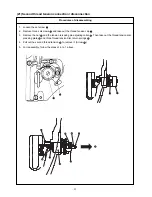

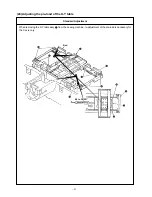

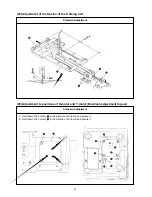

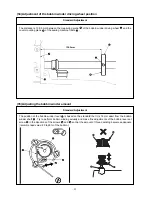

1. Loosen 4 set screws

securing the X motor

.

2. Hold down the X motor

in the direction of Arrow A and tighten 4 set

screws

to secure the X motor

.

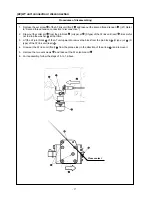

3. Loosen 2 set screws

, 2 set screws

, all of which secure the Y

motor

, and 2 set screws

securing the Y motor mounting plate

.

4. Hold down the Y motor

in the direction of Arrow B and tighten 2 set

screws

that are positioned upper. Then, tighten 2 set screws

that are positioned lower and 2 set screws

securing the Y motor

mounting plate

.

o If the X motor or Y motor is held

down inadequately, feeding gear

backlash is increased and needle

l o c a t i o n a c c u r a c y m a y b e

reduced. In addition, feeding error

may be caused resulting in needle

breakage, and other problems.

o If the pushing is excessive, the

load of the feed will become large,

causing the failure of the feed.

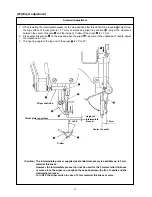

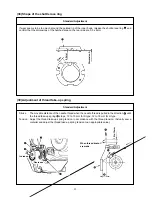

Adjustment Procedures

Results of Improper Adjustment

Adjustment Procedures

Results of Improper Adjustment

o If the tension is excessive, it will

cause timing belt

breakage.

o If the tension is too low, it will

cause failure of the feed.