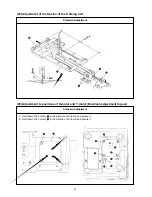

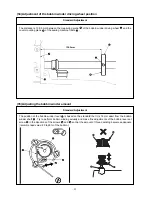

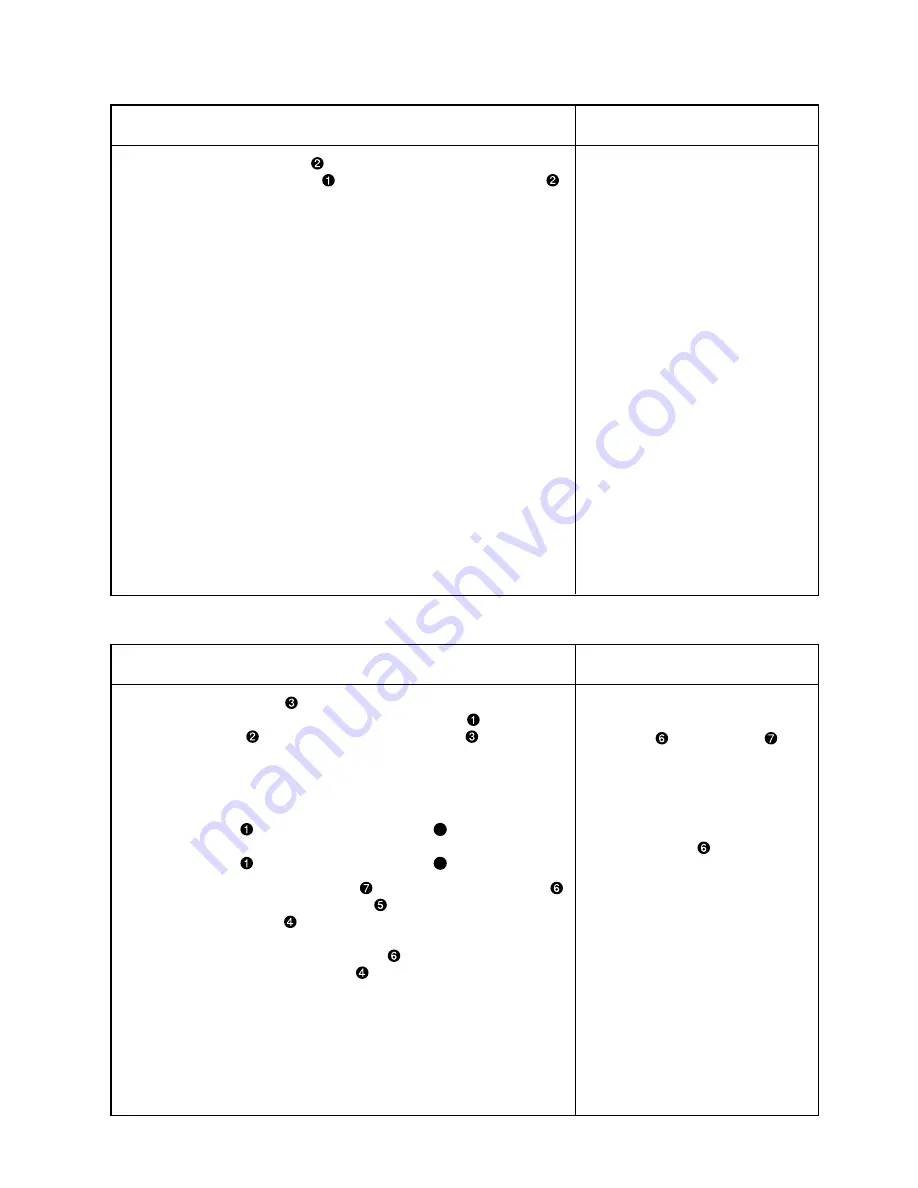

1. Loosen the two set screws

to adjust the position (139.5mm) of the

bobbin winder driving wheel

and fix it with the two set screws

.

o If the distance of 139.5mm is

insufficient, rubber ring wear may

occur in the bobbin winder unit.

In addition, the bearing life may

be reduced in the bobbin winder

unit.

o If the distance of 139.5mm is ex-

cessive, normal thread winding

may fail. In addition, this will also

cause rubber ring slippage in the

bobbin winder unit and give rise

to wear.

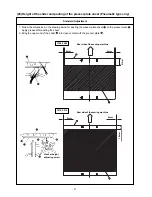

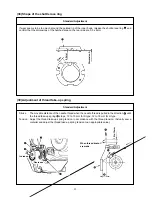

1. Loosen the set screw

of the bobbin winder lever and adjust the

distance to 14mm between the bobbin winder lever

and the bob-

bin winder shaft

. After that, tighten the set screw

of the bobbin

winder lever.

2. Start the sewing machine and wind the thread at the bobbin winder.

Confirm the amount of winding.

1) If the amount of winding seems to be too much, adjust the bobbin

winder lever

in the direction of the arrow

B

.

2) If the amount of winding seems to be too less, adjust the bobbin

winder lever

in the direction of the arrow

A

.

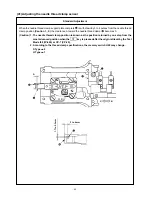

3. If the winding state of the thread

around the bobbin winder

seems to be uneven, loosen the nut

and adjust the height of the

thread tension control

.

(Example) If the amount of the wound thread is less on the upper

side of the bobbin winder

as illustrated, adjust the

thread tension control

upwards.

o If too much thread is wound

(thread protruded from the bobbin

winder

), the thread

will

come in contact with the inside of

the bobbin case and this can be

a cause of sewing deficiency.

o If the amount of thread winding is

uneven at top and bottom of the

bobbin winder

, stitch perfora-

tion may become irregular.

– 56 –

Adjustment Procedures

Results of Improper Adjustment

Adjustment Procedures

Results of Improper Adjustment