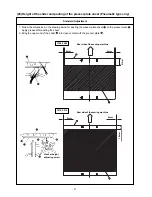

1. Remove the work feed bar, feed plate, and the throat plate. Adjust

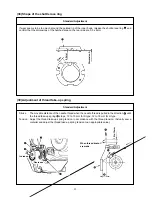

the positioning of shuttle upper spring

with the set screws

(2

pcs.).

2. Using the set screw

, adjust the amount of overlapping D for the

lower thread holder

and the shuttle upper spring

.

(Caution) The right and left positions can also change during (15)

hook adjustments. Position adjustment for the shuttle

upper spring

should be done after the completion of

standard hook adjustment, without fail.

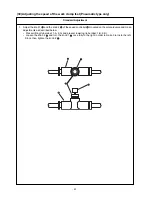

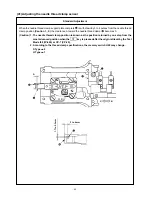

o If there is a front and rear

displacement or a right and left

displacement, needle thread

biting may occur into the hook.

Too much motion to the rear side

will cause the moving knife to fail

to hook the needle thread.

o Too much motion to the rear side

will cause the moving knife to fail

to hook the needle thread.

o Too much motion to the left side

will cause the moving knife to fail

to hook the bobbin thread.

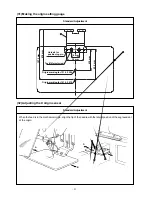

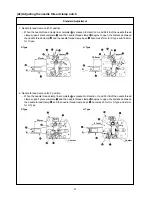

1. If the shuttle felt

seems to be protruded or it has been replaced

with a new one, push it in by means of tweezers or the like.

(Caution) Do not push it in excessively. Align the height and the

plane of the shuttle race

.

2. Confirm that the shuttle packing

has been mounted assuredly.

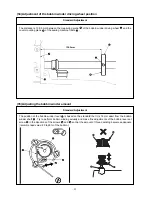

o If the shuttle felt

is protruded,

this will be turned into a rotary load

of the inner hook, causing a

sewing error.

o If the shuttle felt

is missing or

pushed in too much, this will re-

sult in hook lubrication deficiency,

causing hook overheating and

wear.

o If the shuttle packing

has been

missing, the shuttle felt

and

others may be lost, and this can

be a cause of shuttle heating and

wear.

– 58 –

Adjustment Procedures

Results of Improper Adjustment

Adjustment Procedures

Results of Improper Adjustment