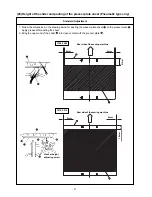

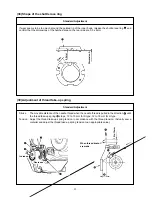

1. If the dimensions of 0.3 x 8mm are not secured, retouching is re-

quired with the aid of an oil stone.

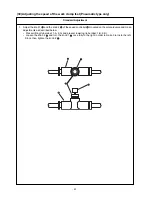

1) Stroke adjustment

Loosen the set screw

, and turn the thread tension assembly

.

Turning it clockwise increases the movable distance and thread draw-

ing amount.

2) Adjustment of thread take-up spring tension

Turn the thread tension post

using a thin driver with the set screw

tightened to adjust the thread take-up spring

tension. Turning

it clockwise increases the thread take-up spring

tension, and turn

it counterclockwise decreases the tension.

(Caution) Set the stroke of the thread take-up spring

shorter

for thin threads with thread number #50 or higher.

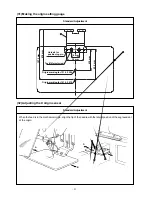

o If the stroke of the thread take-up

spring is larger than the specified

value:

Length of remaining needle

thread is shortened, causing the

needle thread to slip off the needle

at the sewing start.

o If the stroke of the thread take-up

spring is smaller than the speci-

fied value:

Needle thread breakage will oc-

cur at the time of thread trimming

when using a thin thread.

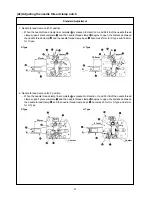

(Caution)

If the thread take-up spring

interferes with the L-shaped

thread guide

, the thread take-

up spring

may fail to return to

the initial position before thread

trimming, and the length of re-

maining needle thread may be

short. If such a trouble occurs,

bend the section

C

C

C

C

C

of the thread

take-up spring

to widen the

clearance

B

B

B

B

B

.

– 60 –

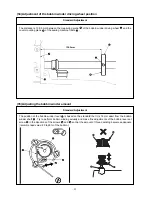

Adjustment Procedures

Results of Improper Adjustment

Adjustment Procedures

Results of Improper Adjustment

Part No.

Name of part

Remarks

0.8

14103253

Shuttle race ring A

Optional

1.3

14103352

Shuttle race ring B

Standard

1.7

14103659

Shuttle race ring C

Optional

1.9

B1817210DAD

Shuttle race ring D

Optional

Dimension A

(mm)