– 27 –

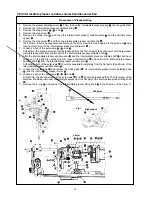

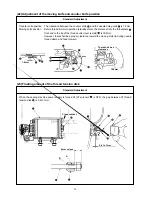

1. Loosen the setscrew

and remove it.

2. When the adjusting screw

is tightened, the quantity of oil can be

regulated for the lubrication pipe left

.

3. After adjustments, tighten the setscrew

to fix it.

(Cautions) 1. In the state of standard shipping, the hook lubrica-

tion reducer

is positioned so that it is lightly tight-

ened and the adjusting screw

is return-loosened

by 4 turns.

2. When reducing the oil amount, the screw should not

be tightened up fully. Tighten the hook lubrication

reducer

and then return it by two turns. In this

position, wait for half a day to see how it goes. Too

much reduction can be a cause of hook wear.

o If the amount of hook lubricant is

reduced too much, this can be a

cause of frictional wear of the

hook race plane or lock-up.

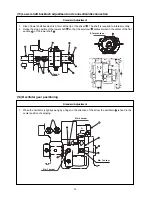

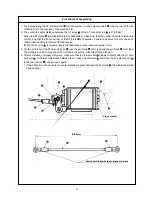

1. Pass the two lubrication pipes

and

and the oil drain pipe

through the frame, and mount the shuttle

.

2. Hold the lubrication pipes

and

with the pipe holder

and fix them with the setscrews

.

3. Fix the two lubrication pipes

and

with the cord clamps

and the setscrews

.

At that time, make sure not to permit the lubrication pipes

and

to come in contact with the needle thread

clamp connector link.

4. Insert the two lubrication pipes

and

in the oil tank

and fix this oil tank

to the frame with the

setscrews

.

5. Fix the waste oil pipe

with 2 setscrews

in two positions by means of the cord clamps

.

6. Insert the oil drain pipe

in the oil reservoir

.

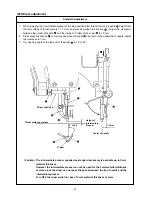

7. Fix the shuttle

and mount the driver

with the setscrew

. Refer to [(18) Hook adjustment].

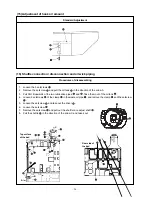

Adjustment Procedures

Results of Improper Adjustment

Procedures of assembling