– 45 –

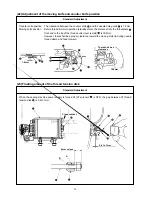

1. Loosen 2 each of the setscrews

and setscrews

.

2. Press the X feed stepping motor

in the direction of the arrow to

reduce the backlash to zero.

3. Tighten the setscrews

and setscrews

.

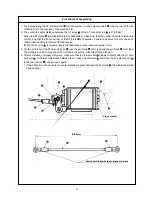

1. Remove 4 setscrews

and take out the Y feed stepping motor

.

2. Confirm that distance is kept 40.7 to 40.8mm between the tip of the Y

drive bevel gear

and the spigot joint of the Y feed stepping motor

.

If this distance is not secured, loosen 2 setscrews

to remove the Y

drive bevel gear

and adjust the number of teeth of the Y drive

bevel gear spacer

.

(The spacer thickness is 0.1mm. Usually, two pieces are used.)

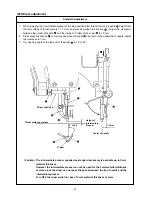

(Caution) When tightening the setscrews

, try to join the flat

section of the shaft of the Y feed stepping motor

with

the position of the setscrew

. At that time, confirm that

the Y drive bevel gear

does not move in the axial

direction.

3. Install the Y feed stepping motor

on the bed.

4. Press the Y trailing gear

in the direction of the arrow to reduce the

backlash to zero and tighten 2 setscrews

. At that time, join the flat

section of the Y drive shaft

with the position of the setscrew

.

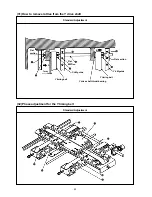

o If there is any backlash, needle

entry accuracy is lowered. This

can also be a cause of feed error.

o Too much pressing may result in

an increase in the feed load, thus

causing feed error.

Adjustment Procedures

Results of Improper Adjustment

Adjustment Procedures

Results of Improper Adjustment

o If there is any backlash, needle

entry accuracy is lowered. This

can also be a cause of feed error.

o Too much pressing may result in

an increase in the feed load, thus

causing feed error.