– 5 –

3

3

2

Within 0.3 mm

3

1. Fix the throat plate auxiliary

cover

3

so that is higher

than the throat plate

2

(within

0.3 mm). When it is lower than

the throat plate

2

, needle

breakage or the like due to the

defective feed will be caused.

2. Confirm by putting a ruler or

the like that the throat plate

auxiliary cover

3

is horizon-

tally installed. If not, throat

plate auxiliary cover

3

and

lower plate

1

come in contact

partially with each other, and

abnormal worn-out will be

caused.

3

7

6

2

1

9

45

8

0.8

to

1.0mm

to

1.0mm1.0mm

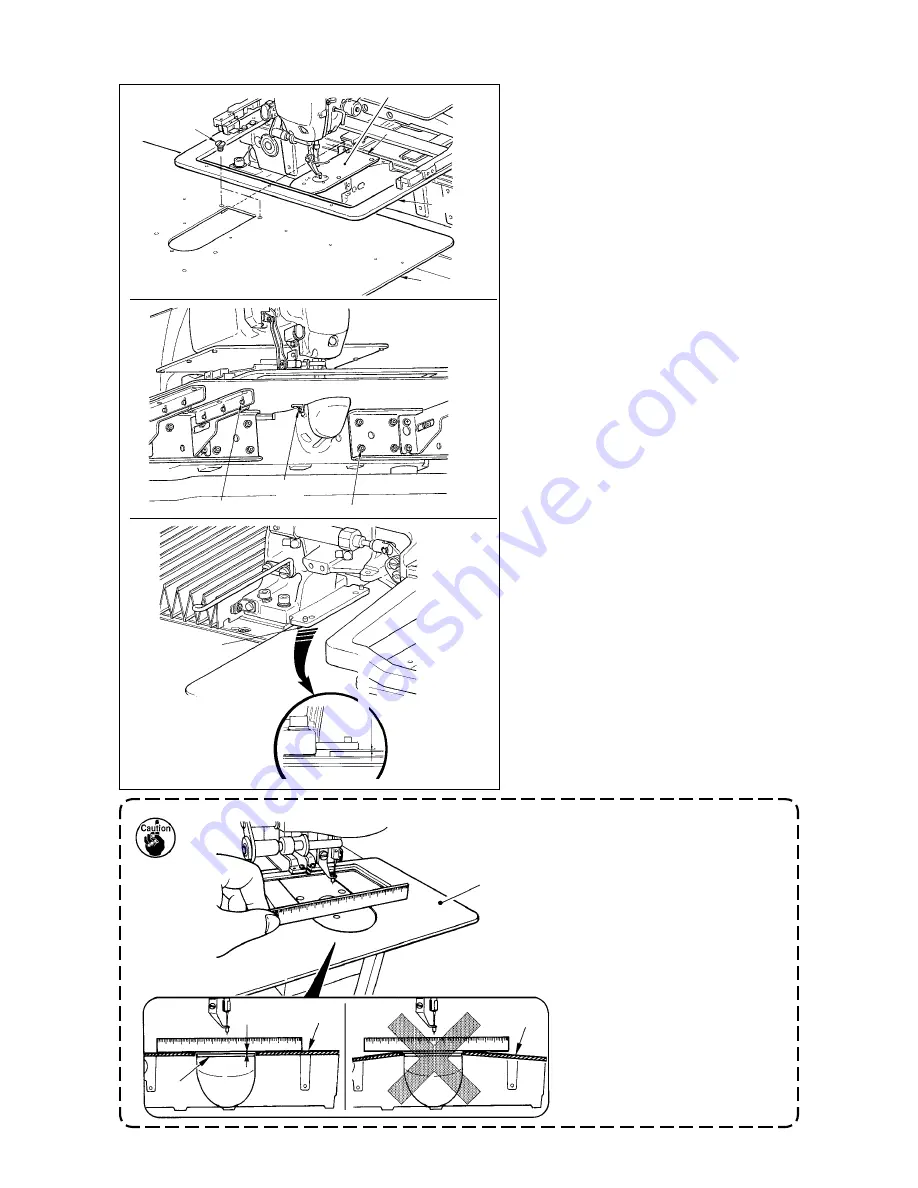

1) Move the cloth feed base to the rear, and

place throat plate auxlary cover (asm.)

3

from between lower plate

1

and

throat plate

2

. At ths tme, be careful not

to bend or damage lower plate

1

.

2) Temporarily fix throat plate auxiliary

cover (asm.)

3

wth throat plate auxl-

ary cover setscrew

5

and washer

4

.

3) Temporarily fix throat plate auxiliary

cover (asm.)

3

to the machne bed

wth throat plate auxlary cover support

setscrews

6

(10 pcs.).

4) Fx throat plate auxlary cover (asm.)

3

to the machne bed wth two coun-

ter-sunk screws

7

.

5) Move the cloth feed base to the left

front, move up and down throat plate

auxlary cover (asm.)

3

so that a ds-

tance of 0.8 to 1.0 mm s provded be-

tween the bottom surface of lower plate

nstallng base

8

and the top surface

of throat plate auxlary cover (asm.)

3

,

and fix setscrews

6

.

6) Perform the smlar work by movng the

cloth feed base to the rght front.

7) Fx throat plate auxlary cover setscrew

5

.

8) Referrng to the cauton below, perform

postonng of the throat plate auxlary

cover. When the postonng s not per-

formed enough, perform the postonng

after loosenng once throat plate auxl-

ary cover setscrew

5

and throat plate

auxlary cover base setscrews

9

.

[When using area 3020]