– 115 –

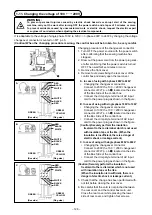

1. MAINTENANCE

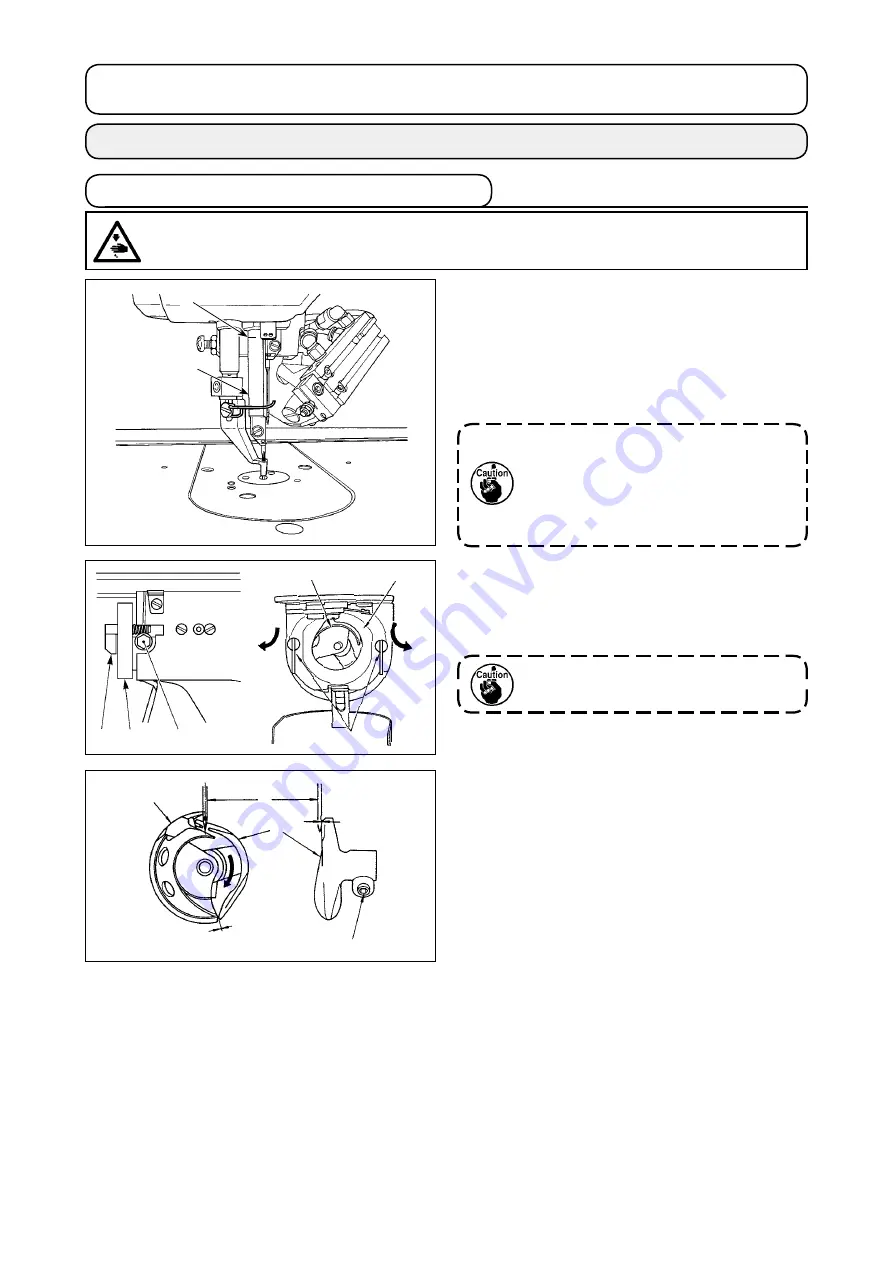

1-1. Adjusting the needle-to-shuttle relation

* Turn ON the power once, and turn OFF the

power again after making the intermediate

presser in the lowered state.

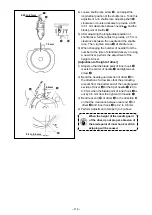

1) Turn the pulley by hand to lift needle bar

❶

from its lowest point until marker line

❷

is

aligned with the bottom end of the needle bar

frame.

III

. MAINTENANCE OF SAWING MACHINE

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of

the sewing machine.

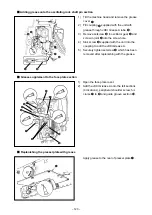

2) Loosen setscrew

❸

in the driver. Drawing

bobbin case opening lever hook

❹

toward you,

open it to the right and left until bobbin case

opening lever

❺

comes off.

At this time, be careful not to let shut

-

tle

❻

come off and fall.

1.

Use the left needle for adjustment.

2.

In the case the right and left needles

differ in the count, use the thinner

one as the left needle and carry out

adjustment.

❶

0 mm

0 mm

❸

❸

❺

❻

❹

❹ ❺

❻

❼

❽

❷

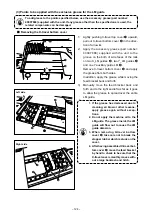

3) Adjust so that the point of shuttle

❻

meets the

center of needle

❼

, and that a clearance of 0

mm is provided between the front end face of

driver

❽

and needle as the front end face of

driver receives needle to prevent the needle

from being bent. Then tighten setscrew

❸

.