– 94 –

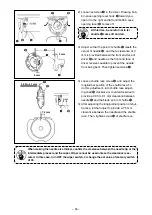

1-1. adjusting the height of the needle bar (changing the length of the needle)

* turn oN the power once, and turn oFF the power again after making the intermediate press-

er in the lowered state.

1) Brng needle bar

1

down to the lowest poston of ts stroke. Loosen needle bar connecton screw

2

and adjust so that the upper marker lne

3

engraved on the needle bar algns wth the bottom end of

the needle bar bushng lower

4

.

2) As illustrated in the above figure, change the adjusting position in accordance with the needle count.

after the adjustment, turn the pulley to check for an extra load.

1. MaINtENaNcE

5

: Market line for DP x 17

(with needle count higher than #22)

6

: Marker line for DP x 17

(with needle count lower than #22)

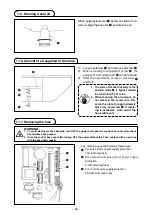

1-2. adjusting the needle-to-shuttle relation

5

: Marker line for DP x 17

needle (with needle count

higher than #22)

6

: Marker line for DP x 17

needle (with needle count

lower than #22)

3

: When DP x 17 needle (of

which needle count is

lower than #22) is used.

3

: When DP x 17 needle (of

which needle count is

higher than #22) is used.

* turn oN the power once, and turn oFF the

power again after making the intermediate

presser in the lowered state.

1) Turn hook drvng shaft pulley

1

by hand and

adjust lower engraved marker lne

3

to the

bottom end of needle bar lower metal

4

when

needle bar

2

goes up.

#

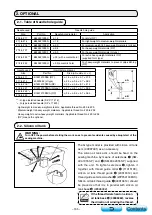

. MaINtENaNcE oF SaWING MacHINE

WarNING :

turn oFF the power before starting the work so as to prevent accidents caused by abrupt start of

the sewing machine.

WarNING :

turn oFF the power before starting the work so as to prevent accidents caused by abrupt start of

the sewing machine.

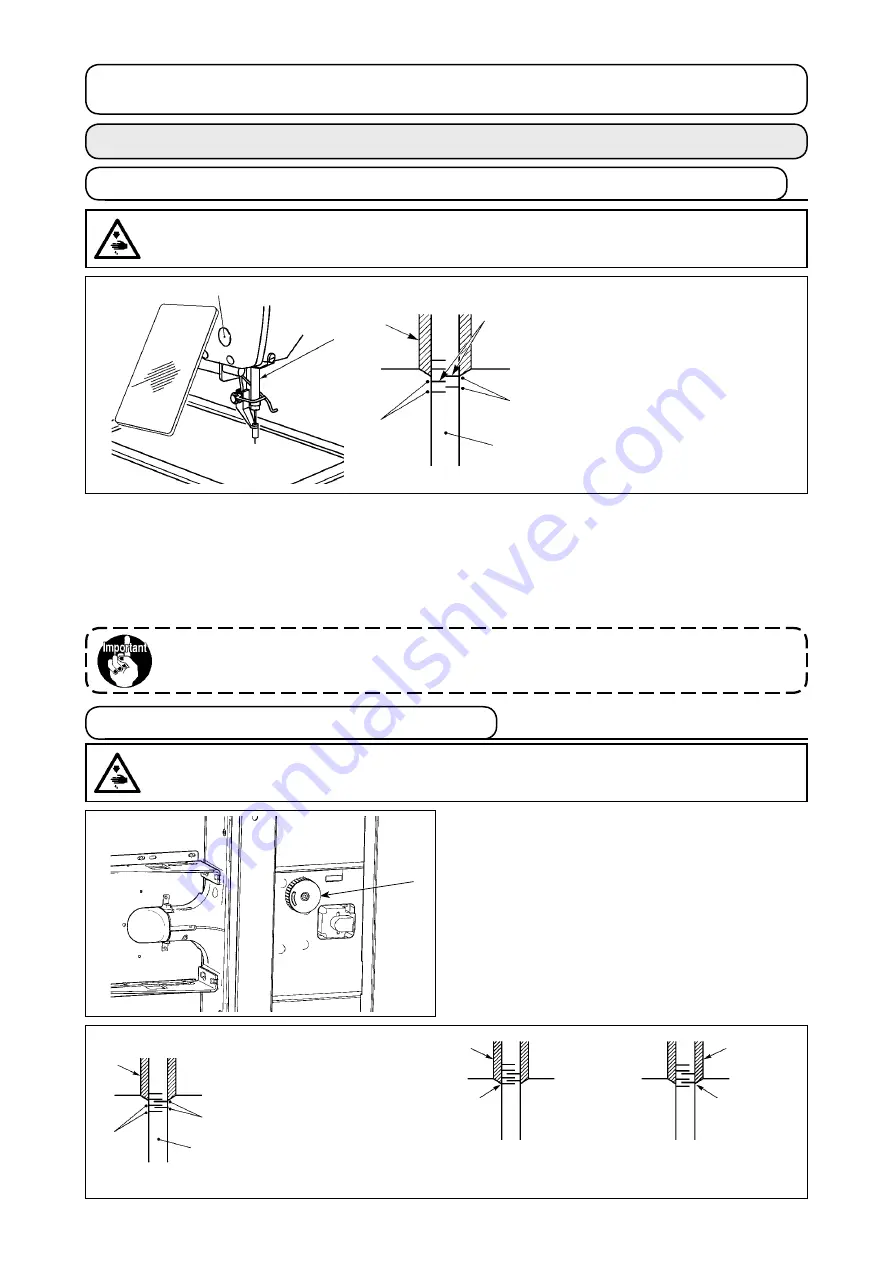

1

2

1

4

3

5

6

4

6

3

4

5

2

1

3

4