– 98 –

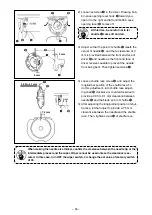

1-7. Needle thread clamp device

1) When thread s caught at top

end

1

of the thread clamp,

thread clamp becomes n-

complete and sewng trouble

at the sewng start wll be

caused. Perodcally remove

and clean the throat plate

snce waste thread or thread

dust s apt to gather n the

places wth crcle mark.

WarNING :

turn oFF the power before starting the work so as to prevent accidents caused by abrupt start of

the sewing machine.

1

1

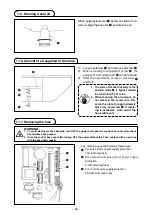

1-8. thread breakage detector plate

1) Adjust so that thread breakage detector plate

1

s always n contact wth thread take-up sprng

2

n the absence of needle thread. (Slack :

approx. 0.5 mm)

2) Whenever the stroke of thread take-up sprng

2

has been changed, be sure to readjust

thread breakage detector plate

1

. To make

ths adjustment, loosen screw

3

.

adjust so that thread breakage de-

tector plate

1

does not touch any

adjacent metallic parts other than

thread take-up spring

2

.

2

3

1

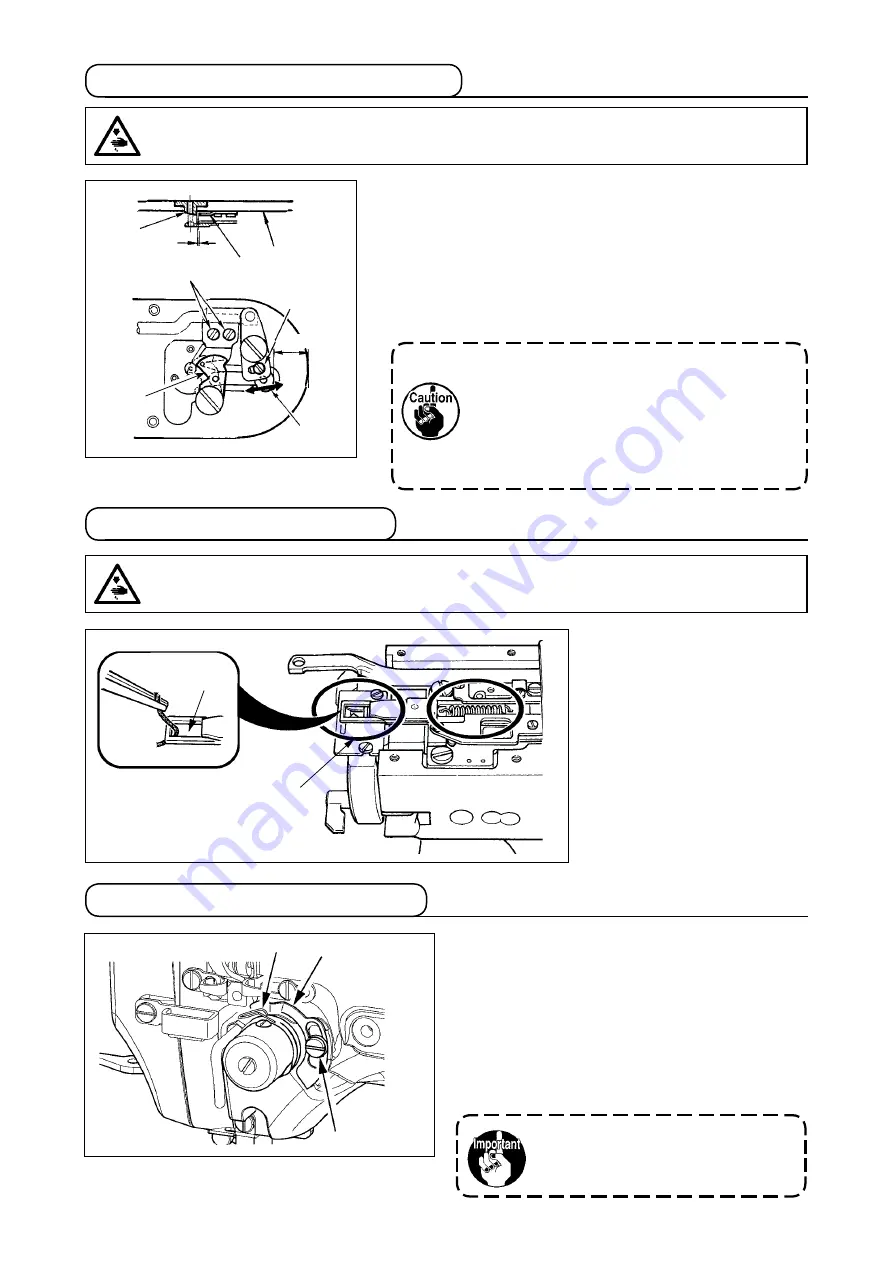

1-6. the moving knife and counter knife

1.0 mm

1) Loosen adjustng screw

1

so that a clearance of 18.5

mm s provded between the front end of the throat plate

and the top end of thread trmmer lever, small

3

. To

adjust, move the movng knfe n the drecton of arrow.

2) Loosen setscrew

5

so that a clearance of 1.0 mm s

provded between needle hole gude

2

and counter

knfe

4

. To adjust, move the counter knfe.

When moving knife

6

interferes with the

top end of the needle thread clamp (refer to

-1-7. Needle thread clamp device", p.98

Set the adjustment value to approximately

18 mm and open the clearance since thread

clamp error or breakage of the thread clam

will be caused.

throat plate

1

2

5

4

3

WarNING :

turn oFF the power before starting the work so as to prevent accidents caused by abrupt start of

the sewing machine.

6

18.5 mm