− −

!

. CAUTIONS BEFORE OPERATION

Following items have to be checked every working day before the operation of the machine

and before the start of work hours.

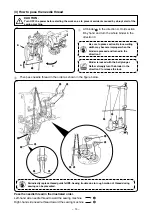

1. Ascertain that the sewing machine is filled with the predetermined amount of oil.

2. Never operate the machine unless the lubricating part in the hook has been filled up with oil.

3. Ascertain that the pressure gauge indicates the designated air pressure of 0.5 MPa.

*

(This is necessary particularly when the compressor is stopped for a lunch break or the like.)

If the compressed air pressure is equal to or less than the designated value, troubles such

as interference between the parts can occur. It is therefore necessary to carefully check the

compressed air pressure.

4. Check whether the needle thread/bobbin thread need to be replenished.

5. To perform sewing immediately after turning ON the power switch, perform trial stitching

first, then proceed with sewing of actual products after the test sewing.

6. In order to prevent the optical fiber sensor of the bobbin thread remaining amount detecting

device from showing a detecting failure, be sure to clean thread waste around the hook

using an air gun once or more times a day.

7. In order to protect the flap sensor from showing a detecting failure, be sure to clean dust on

the reflecting tape of the folding plate using an air gun once or more times a day.