− 95 −

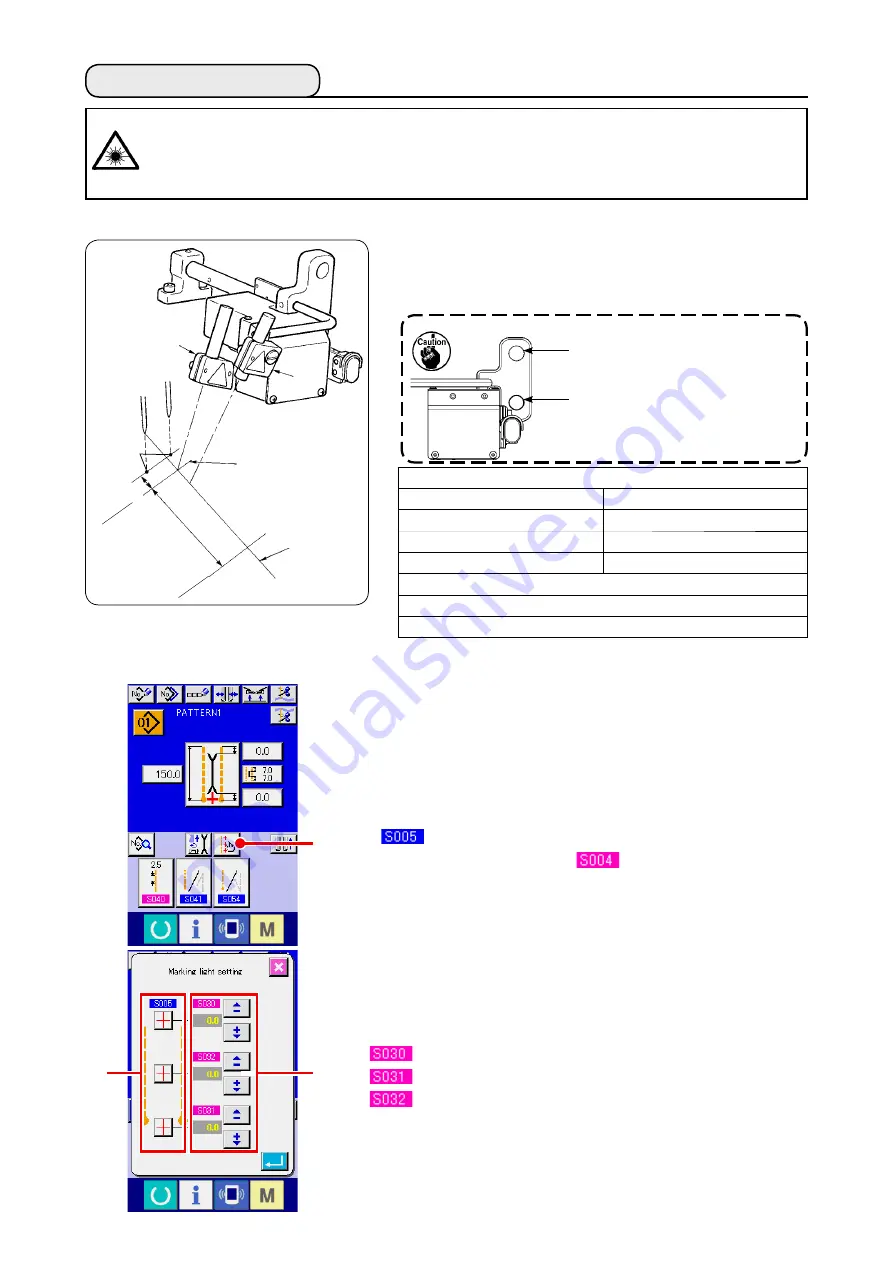

2. MARKING LIGHT

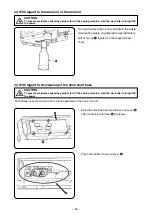

(1) Marking light for sewing reference setting

The light of marking light on the front side observed from the

operator side is used for longitudinal line reference setting

(fixed)

A

and that in the rear side is used for lateral line

reference setting (moving according to the sewing type)

B

.

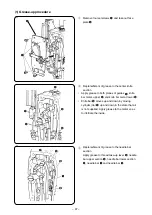

(2) Adjusting the marking light irradiation position

A

Press button

A

in the input screen and the marking light setting

screen is displayed. Then the irradiation position of marking light

can be adjusted.

Lateral line irradiation position of marking light is determined by the

sewing type, and the irradiation position is automatically moved

by

B

change-over of sewing start irradiation/sewing end

irradiation/center irradiation” and “

L size setting”.

When the compensation value of

C

is 0.0 mm, the marking light

irradiates the sewing position.

A

C

B

When you desire to move the marking light irradiation position in

terms of the sewing position, set each compensation value of

C

for

use.

: Sewing start irradiation position compensation

: Sewing end irradiation position compensation

: Center irradiation position compensation

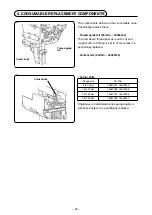

80

mm

Needle

220

mm

B

B

A

Movable range

WARNING

:

1. If the laser light directly enters the eye, eyesight trouble may be caused.

Do not look into the laser inlet/outlet.

2. Never perform installing/removing of the marking lamp with the power turning ON.

In addition, do not use the light other than marking.

• Use installing hole

D

on the

bottom side up to gauge size 8

to 16 mm. In case of 18 mm or

more, use installing hole

C

on

the top side.

• After changing the top or the

bottom installing position, be

sure to perform the adjustment

of marking light motor origin.

C

D

Laser specifications

Lateral line reference laser

Longitudinal line reference laser

Class 2 laser product

Class 2M laser product

Maximum output: 1.0mW

Maximum output: 3.5mW

Wave length: 650nm

Wave length: 650nm

Safety standard

JIS C 6802:2011

IEC60825-1+A2:2007