– 0 –

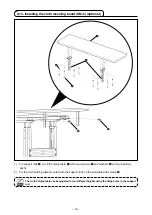

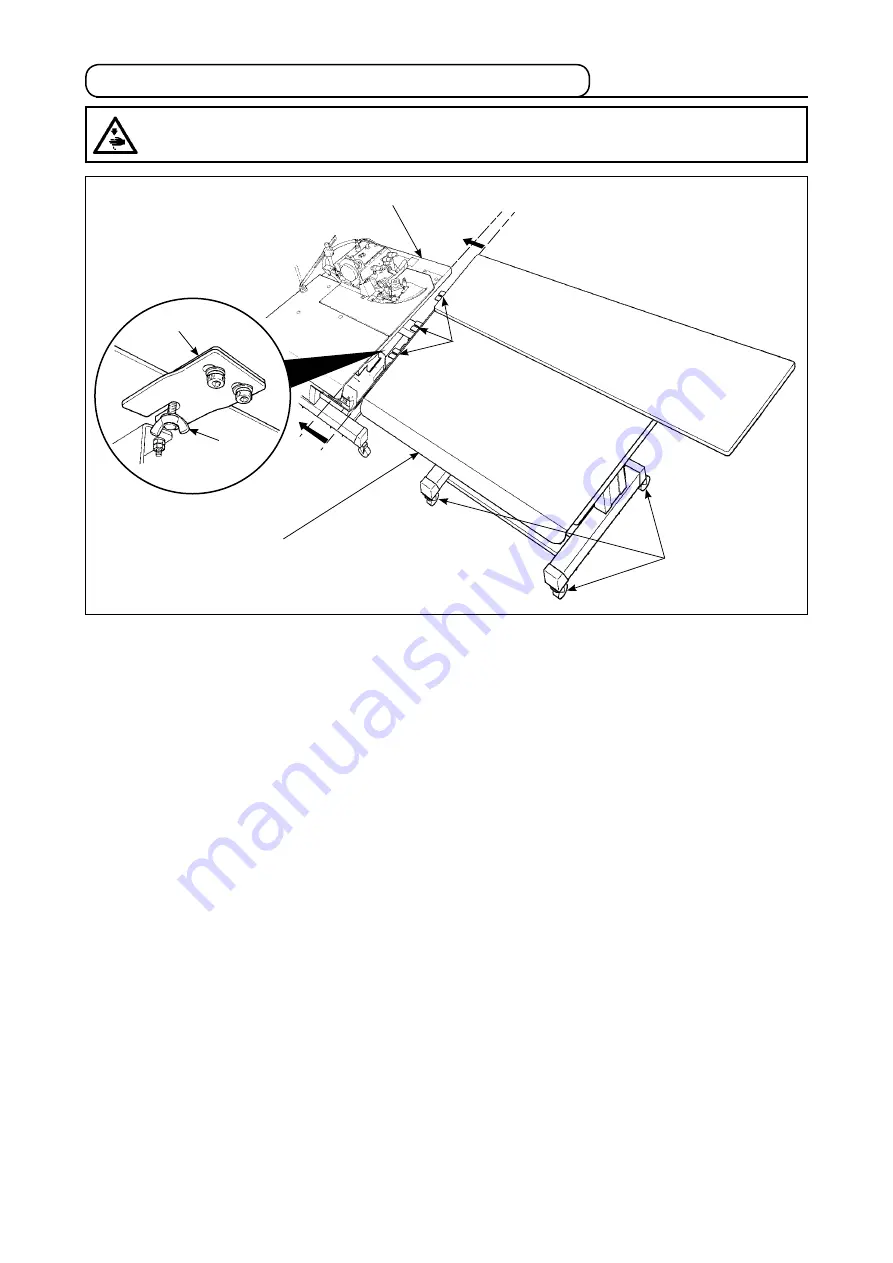

3-11. Joining the sub-table (only for the long table type)

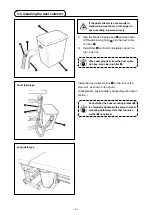

Butting the sub-table and the main-body table with no clearance provided between them, fix clips

1

(at three

locatons) wth thumbscrews

2

. Lock casters

3

(at four locatons) to secure the sub-table.

1

3

Sub-table

Main-body table

2

4

CAUTION

:

Connect the sub-table to the main-body table taking care not to allow your fingers caught between

them.

A dfference n heght between the top face of the man-body table and that of the sub-table may be observed

on some nstallaton ste.

If such a dfference s observed, adjust so that the tables are same n heght wth spacers

4

for adjustng the

heght of the clps. (Three spacers are suppled.)

・

If the sub-table s lower than the man-body table :

Add the suppled spacer(s) approprately.

・

If the sub-table s hgher than the man-body table :

Remove spacer

4

and change wth a thnner one.