– 1 –

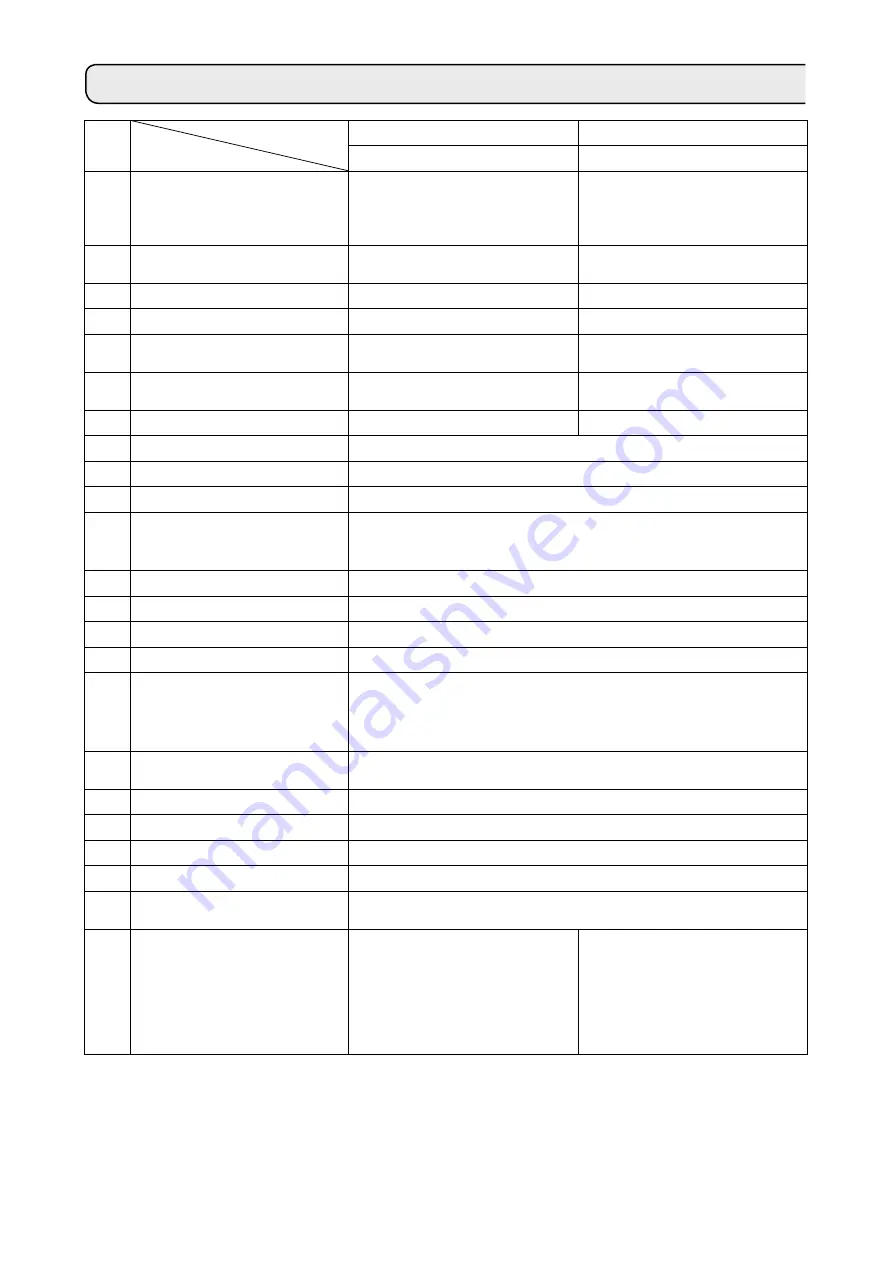

I. SPECIFICATIONS

No.

Model name

Item

DDL-7000AS-7

DDL-7000AH-7

Light- to medium-weight materials

Heavy-weight materials

1

Max. sewing speed

Stitch length less than 4mm

5,000sti/min

Stitch length 4mm or more

4,000sti/min

Stitch length less than 5mm

4,000sti/min

Stitch length 5mm or more

3,500sti/min

2

Factory-set sewing speed at the

time of shipment

4,000sti/min

3,500sti/min

3

Stitch length

5mm

5mm(

※

)

4

Needle bar stroke

30.7±0.5mm

35±0.5mm

5

Thread take-up lever stroke

Link thread take-up lever 107mm

(106 to 112mm)

Link thread take-up lever 112mm

(108 to 115mm)

6

Needle

*1

DB×1

(

#14

)

#14 to 18

134(Nm90) Nm90 to Nm110

DP×5

(

#21

)

#20 to 23

134(Nm130) Nm125 to Nm160

7

Thread counts that are supported

#

60 to

#

8 (200 to 600dtex)

#

30 to

#

8 (600 to 1200dtex)

8

Amount of lift of the presser foot

Manual: 5.5 mm

,

By knee-lifter: 13 mm

9

Lubrication

Replenishment of oil reservoir (capacity: 450 ml)

10

Lubrication method

Forced lubrication method

11

Lubricating oil

JUKI CORPORATION OIL 7 (equivalent to ISO VG7)

or

NEW DEFRIX OIL No. 1 (equivalent to ISO VG7)

12

Drive system

Main-shaft direct-drive system

13

Electrical box

Integral with the machine head

14

Power switch

3-phase / CE

15

Motor used

AC servomotor, 550 W

16

External dimensions

Distance from machine arm to needle: 260 mm;

height of the machine arm: 130 mm

Arm size: 432 mm x 105 mm; bed size: 476 mm x 178 mm

Entire length: 603 mm

17

Operating temperature /

humidity range

Temperature

:

5˚C

to

35˚C/ Humidity

:

35% to 85%

18

Supply voltage/

Single phase 220V, Rating ± 10 %

19

Frequency

50/60Hz

20

Power consumption

210VA

21

Mass of machine head

Completed machine head 34 kg

22

LED light

(Provided as standard)

Illumination is adjustable in five steps.

23

Noise

Equivalent continuous emission

sound pressure level (L

pA

) at the

workstation:

A-weighted value of 81.0 dBA ; (In-

cludes K

pA

= 2.5 dBA) ; according

to ISO 10821- C.6.2 -ISO 11204

GR2 at 4,000 sti/min.

Equivalent continuous emission

sound pressure level (L

pA

) at the

workstation:

A-weighted value of 83.0 dBA ; (In-

cludes K

pA

= 2.5 dBA) ; according

to ISO 10821- C.6.2 -ISO 11204

GR2 at 4,000 sti/min.

(Caution) Sewing speed differs according to the sewing conditions.

* Stitch length can be maximized to 7 mm by changing over the feed dial and the throat plate with the optional

feed dial (22971402) and the optional throat plate (23645807).