– –

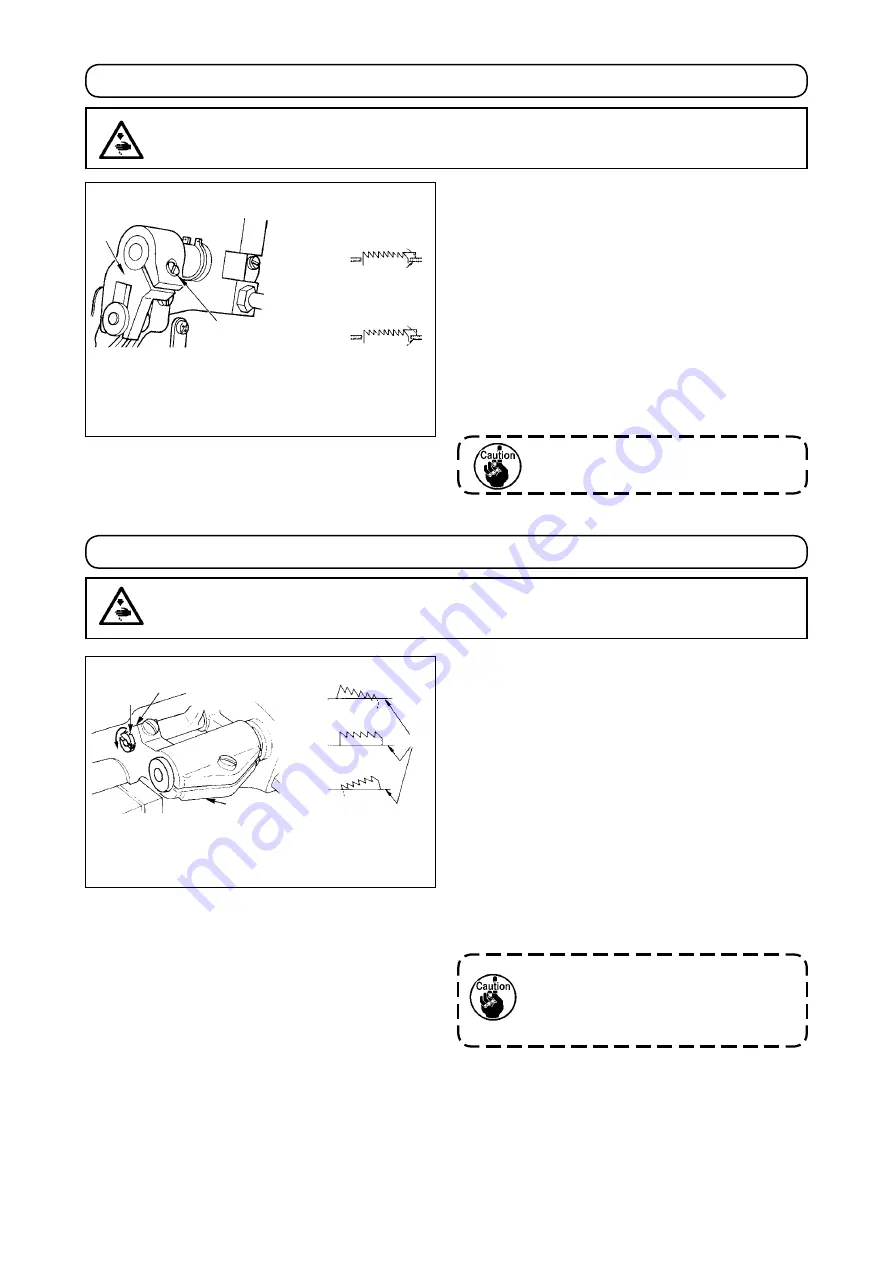

1) The feed dog is factory-adjusted so that it juts out

from the throat plate surface 0.75 mm to 0.85 mm

(0.95 mm to 1.05 mm for DDL-8100eH) .

2) If the feed dog juts out too much, puckerng may

result when sewing light-weight materials.

(Recommended protrusion : 0.7 mm to 0.8 mm)

3) To adjust the heght of the feed dog :

1

Loosen screw

2

of crank

1

.

2

Move the feed bar up or down to make adjust

-

ment.

3

Securely tghten screw

2

.

If the clamping pressure is insufficient,

the forked portion will wear out.

19. HEIGHt oF tHE FEED DoG

a

Feed dog

b

throat plate

0.75 to 0.85 mm

0.95 to 1.05 mm

b

b

) The standard tlt (horzontal) of the feed dog s

obtaned when marker dot

A

on the feed bar

shaft s algned wth marker dot

B

on feed rocker

1

. (DDL-8100eH, the marker dot

B

nclnes for

-

ward the feed rocker shaft by 90°, as standard).

2) To tlt the feed dog wth ts front up n order to pre

-

vent puckerng, loosen the setscrew, and turn the

feed bar shaft 90° in the direction of the arrow,

usng a screwdrver.

3) To tlt the feed dog wth ts front down n order to

prevent uneven materal feed, turn the feed bar

shaft 90° in the opposite direction from the arrow.

(The standard tilt for DDL-8100eH.)

Whenever the feed dog tilt is adjusted,

the feed dog height will be changed.

so, it is necessary to check the height

after tilt adjustment.

20. tILt oF tHE FEED DoG

WarnInG :

to avoid possible personal injury due to abrupt start of the machine, turn off the power to the

machine and check to be sure that the motor has totally stopped rotating in prior.

a

Front up

b

standard

c

Front down

d

throat plate

WarnInG :

to avoid possible personal injury due to abrupt start of the machine, turn off the power to the

machine and check to be sure that the motor has totally stopped rotating in prior.

1

2

a

a

DDL-8100e

DDL-8100eH

1

A

B

a

b

c

d