– 6 –

■

adjusting the amount of oil (oil spots) in the hook

) Turnng the ol amount adjustment screw attached

on the hook driving shaft front bushing in the “+”

drecton (n drecton

A

) wll ncrease the amount

of oil (oil spots) in the hook, or in the “–” direction

(n drecton

B

) wll decrease t.

2) After the amount of ol n the hook has been

properly adjusted wth the ol amount adjustment

screw, make the sewng machne run dle for ap

-

proximately 30 seconds to check the amount of

ol n the hook.

A needle of DBx1 should be used. Select a proper

needle sze accordng to the count of thread and the

type of materal used.

) Turn the handwheel untl the needle bar reaches

the hghest pont of ts stroke.

2) Loosen screw

2

, and hold needle

1

wth ts n

-

dented part

A

facing exactly to the right in direc-

ton

B

.

3) Insert the needle fully nto the hole n the needle

bar n the drecton of the arrow untl the end of

hole s reached.

4) Securely tighten screw

2

.

5) Check that long groove

C

of the needle s facng

exactly to the left in direction

D

.

8. attacHInG tHE nEEDLE

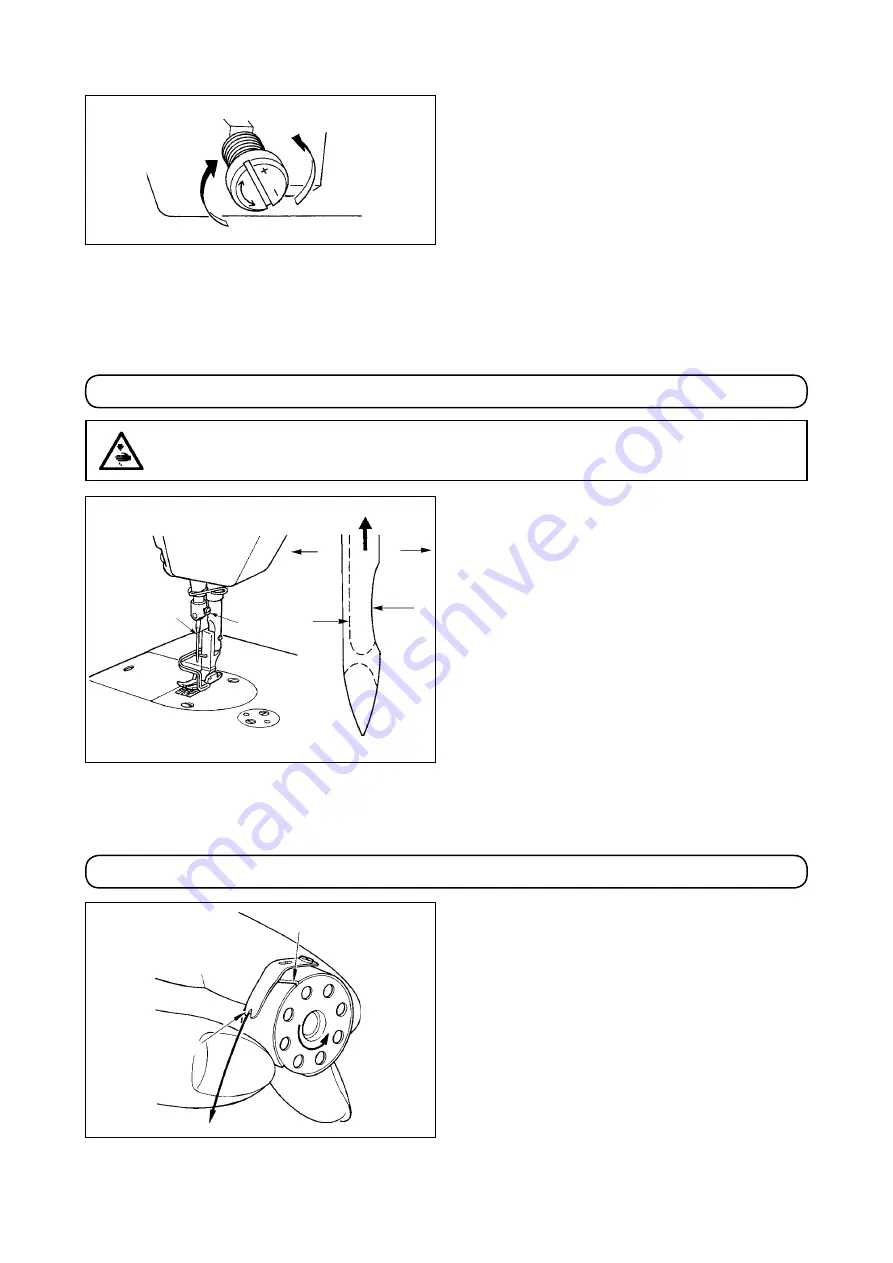

9. sEttInG tHE BoBBIn Into tHE BoBBIn casE

) Install the bobbn n the bobbn case so that the

thread wound drecton s counterclockwse.

2) Pass the thread through thread slt

A

, and pull

the thread n drecton

C

.

By so dong, the thread wll pass under the ten

-

son sprng and come out from notch

B

.

3) Check that the bobbn rotates n the drecton of

the arrow when thread s pulled.

WarnInG :

to avoid possible personal injury due to abrupt start of the machine, turn off the power to the

machine and check to be sure that the motor has totally stopped rotating in prior.

A

B

1

2

D

B

C

A

B

C

A