– 6 –

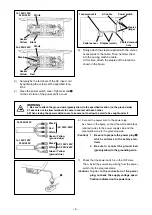

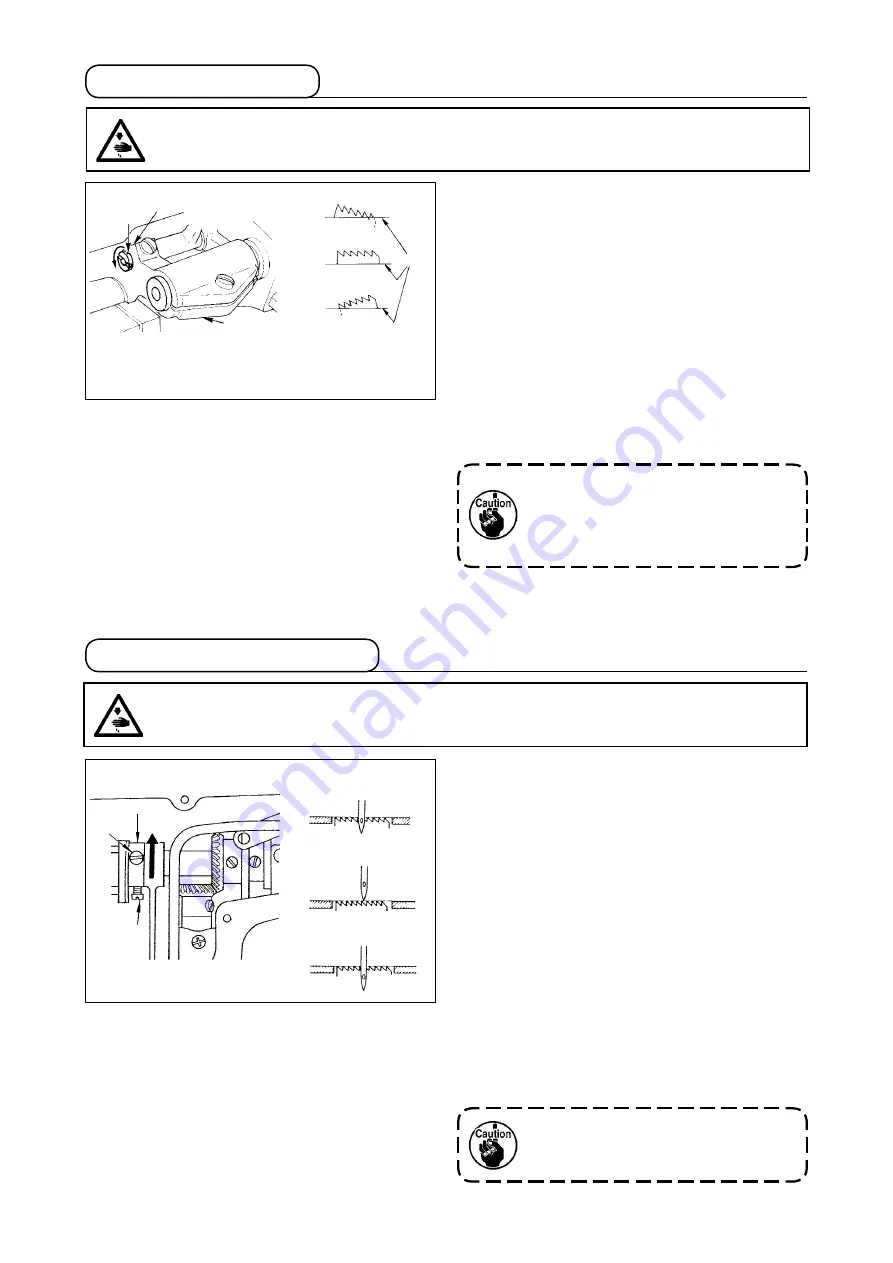

) Loosen screws

2

and

3

n feed eccentrc cam

1

, move the feed eccentrc cam n the drecton

of the arrow or opposte drecton of the arrow,

and firmly tighten the screws.

2) For the standard adjustment, adjust so that the

top surface of feed dog and the top end of needle

eyelet are flush with the top surface of throat plate

when the feed dog descends below the throat

plate.

3) To advance the feed tmng n order to prevent

uneven materal feed, move the feed eccentrc

cam n the drecton of the arrow.

4) To delay the feed tmng n order to ncrease

sttch tghtness, move the feed eccentrc cam n

the opposte drecton from the arrow.

Be careful not to move the feed eccen-

tric cam too far, or else needle breakage

may result.

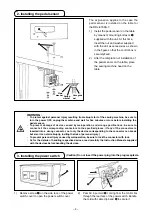

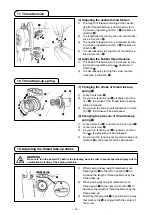

) The standard tlt (horzontal) of the feed dog

s obtaned when marker dot

A

on the feed

bar shaft s algned wth marker dot

B

on feed

rocker

1

.

2) To tlt the feed dog wth ts front up n order to

prevent puckerng, loosen the setscrew, and

turn the feed bar shaft 90˚ in the direction of the

arrow, usng a screwdrver.

3) To tlt the feed dog wth ts front down n order

to prevent uneven materal feed, turn the feed

bar shaft 90˚ in the opposite direction from the

arrow.

Whenever the feed dog tilt is adjusted,

the feed dog height will be changed. So,

it is necessary to check the height after

tilt adjustment.

1

A

B

a

b

c

d

a

Front up

b

Standard

c

Front down

d

throat plate

Standard feed timing

advanced feed timing

Delayed feed timing

1

2

3

22. tilt of the feed dog

23. adjusting the feed timing

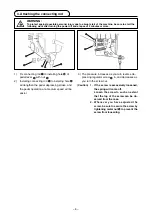

WarNING :

Be sure to turn the power oFF before the following work in order to prevent personal injury due to

unintentional starting of the sewing machine.

WarNING :

Be sure to turn the power oFF before the following work in order to prevent personal injury due to

unintentional starting of the sewing machine.