−

61

−

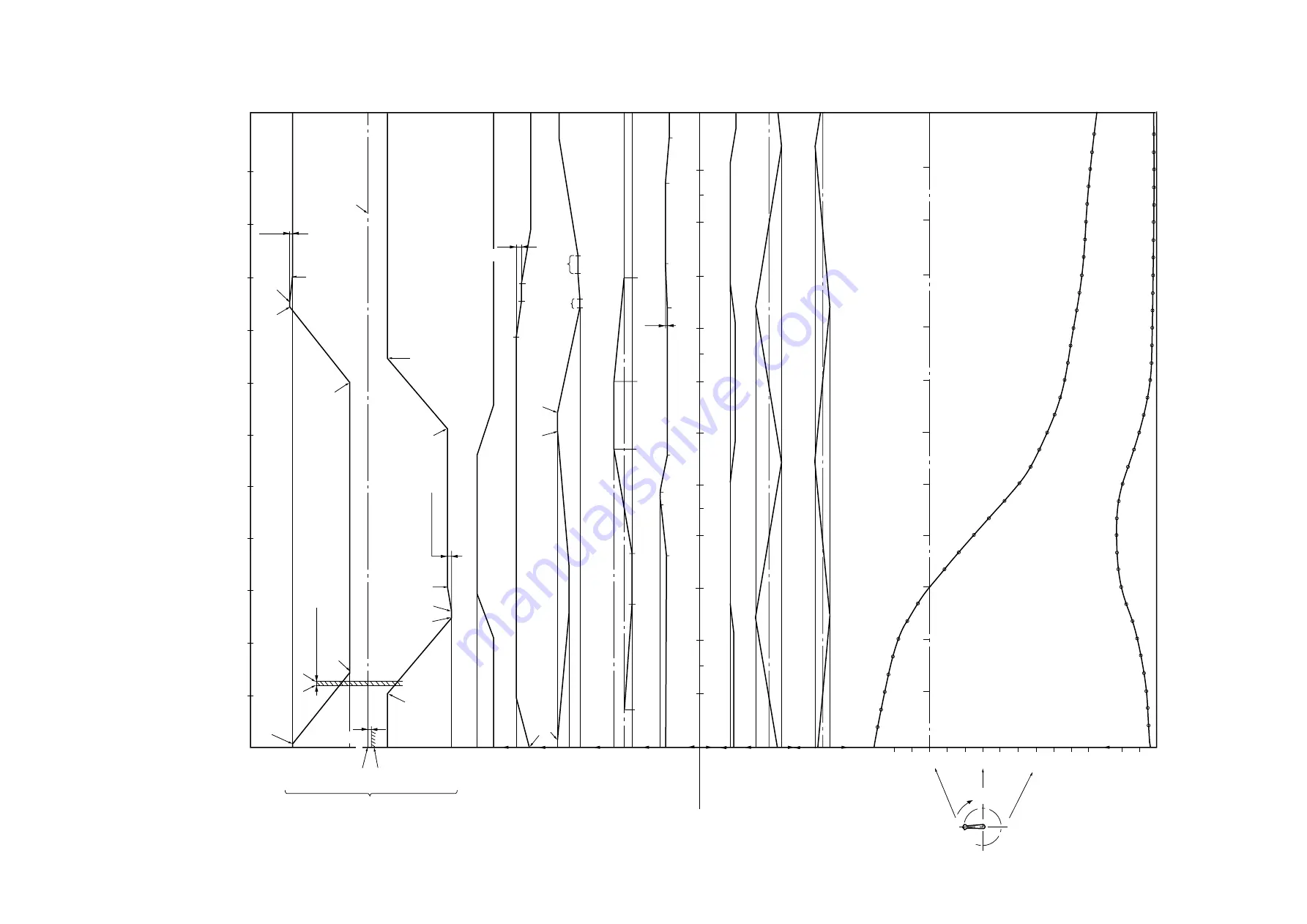

10. TIME CHART

43.9

Height of support cylinder

Lower looper position

Ratio of angle to speed

10.5

Throat

plate

-10.5

-46.5

(Slide case St.)

9

Needle grasping cam

0

(Cam lift)

0

(Cam lift)

13

6.5

Rightlooper cam

6.8

Left looper cam

0

(Cam lift)

10

Thread haul

5

0

(Cam lift)

4

Brush cam

0

1:1 Shaft angle

Double speed shaft angle

(Cam lift)

1.5

Lower feed lifting cam

0

7

Lower feed accentric boss

0

-7

4

Upper feed accentric shaft

0

-4

0˚

180˚

90˚

-90˚

-60˚

-30˚

30˚

60˚

90˚

120˚

150˚

180˚

210˚

240˚

270˚

210R

2

1

0

30

60

90

120

150

180

210

240

270

300

360

29.4˚

35˚

37˚

Most approach section

(Distance : 23.6

±

0.1mm)

1.5 mm

209.4˚

330

252.4˚

255.4˚

270˚

2.6 mm

Needle transfer

72.4˚

75.4˚

90 ˚

Thread haul S +2.6 mm

182˚

222˚

86˚

Thread grasp closing section

42˚

166˚

196˚

60˚

0˚

25˚

Right looper retreat section

235˚

255˚

265˚

2.1mm

295˚

72˚

Neutral section

100˚

180˚

Exreme forward end

190˚

250˚

Retreat

255˚

Stop near to the needle

280˚

345˚

20˚

80˚

Left end stop

110˚

170˚

Right end stop

210˚

270˚

Neutral

360˚

105˚

Full opening

140˚

145˚

165˚

1.5

250˚

275˚

Slight opening section

320˚

345˚

30

90˚

60

90

180˚

120

270˚

210

450˚

240

270

540˚

300

630˚

330

360

720˚

120˚

150

180

360˚

160˚

Lower feed/upper feed

300˚

340˚

480˚

520˚

660˚

700˚

140˚

320˚

500˚

680˚

Presser comes down

Presser goes up.

30

60

90˚

120

150

180˚

210

240

270˚

300

330

Main shaft angle

360

2˚

2˚

270˚

Needle transfer