-17-

-17-

-17-

-17-

-17-

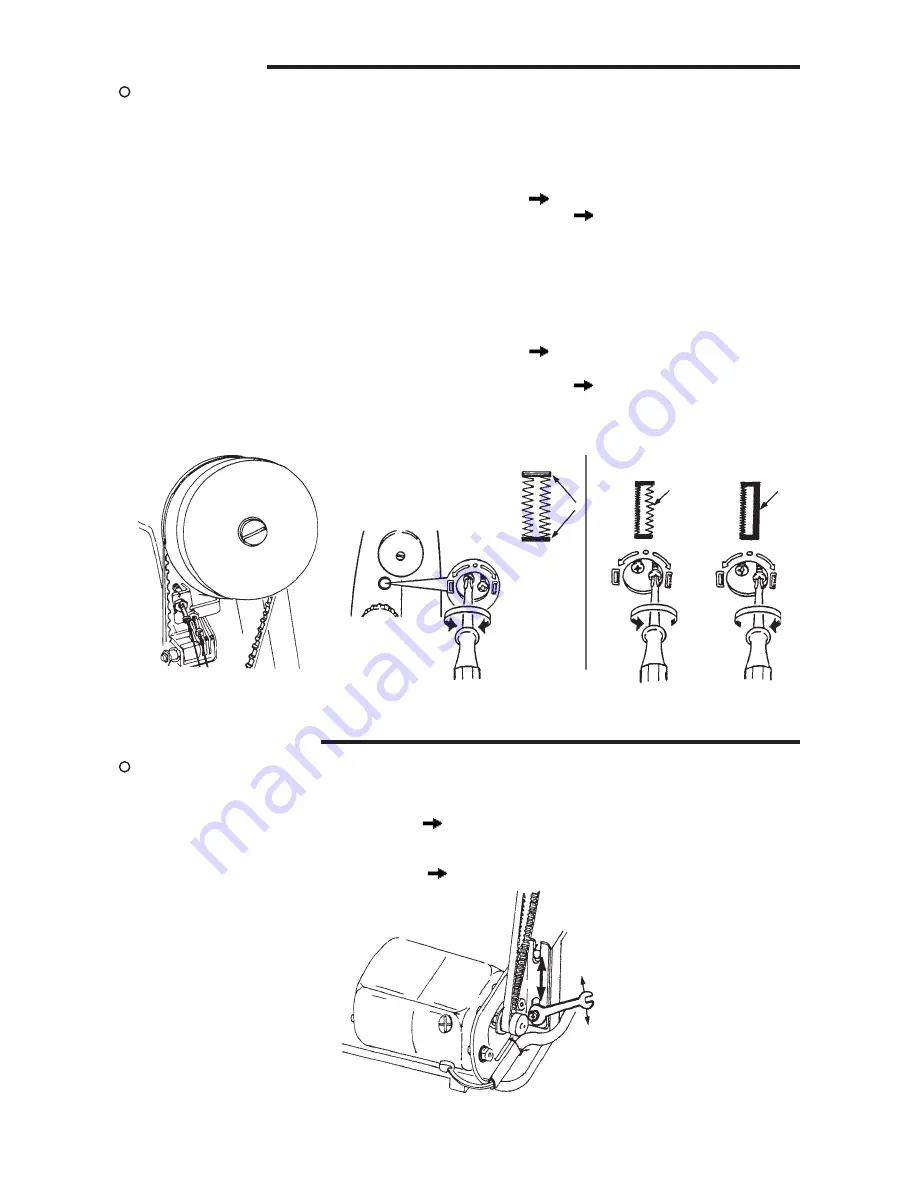

4-19 Button hole

Remove the cover for adjusting the button hole.

Bar tacking adjustment

1. Use the button hole foot and sew a button hole.

2. Turn the adjusting screw located at the upper left side from the hole for adjusting the

button hole with a screwdriver so that the feed amount of bar tacking should be 0 to

1.5 mm.

Turn the adjusting screw clockwise Increase the feed amount.

Turn the adjusting screw counterclockwise Reduce the feed amount.

Feed pitch adjustment

1. Use the button hole foot and sew a button hole.

2. Turn the adjusting screw located at the lower right side from the hole for adjusting the

button hole with a screwdriver so that the feed pitch of the stitches on the right and

left sides should be equal.

If the adjusting screw is turned, the feed pitch of the stitches on the right side will

vary. In this case, set the pitch to the feed pitch of the left side.

Turn the adjusting screw clockwise Increase the feed pitch of the stitches

on the right side.

Turn the adjusting screw counterclockwise Reduce the feed pitch of the

stitches on the right side.

How to adjust

Feed pitch

Bar tacking

4-20 Motor belt tension

Remove the front cover. (Similarly, the face cover, bottom cover and rear cover)

1. Loosen the setscrew of the motor belt and move up or down together with the motor

bracket to adjust the belt tension.

Excessive tension Reducion of max. sewing speed, excessive power

consumption, excessive vibration and excessive

rotation noise.

Insufficient tension Belt-slip

How to adjust