24

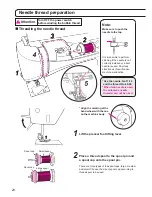

Needle size:

The larger the number, the thicker the needle.

23

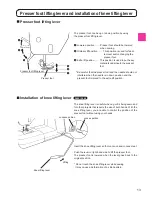

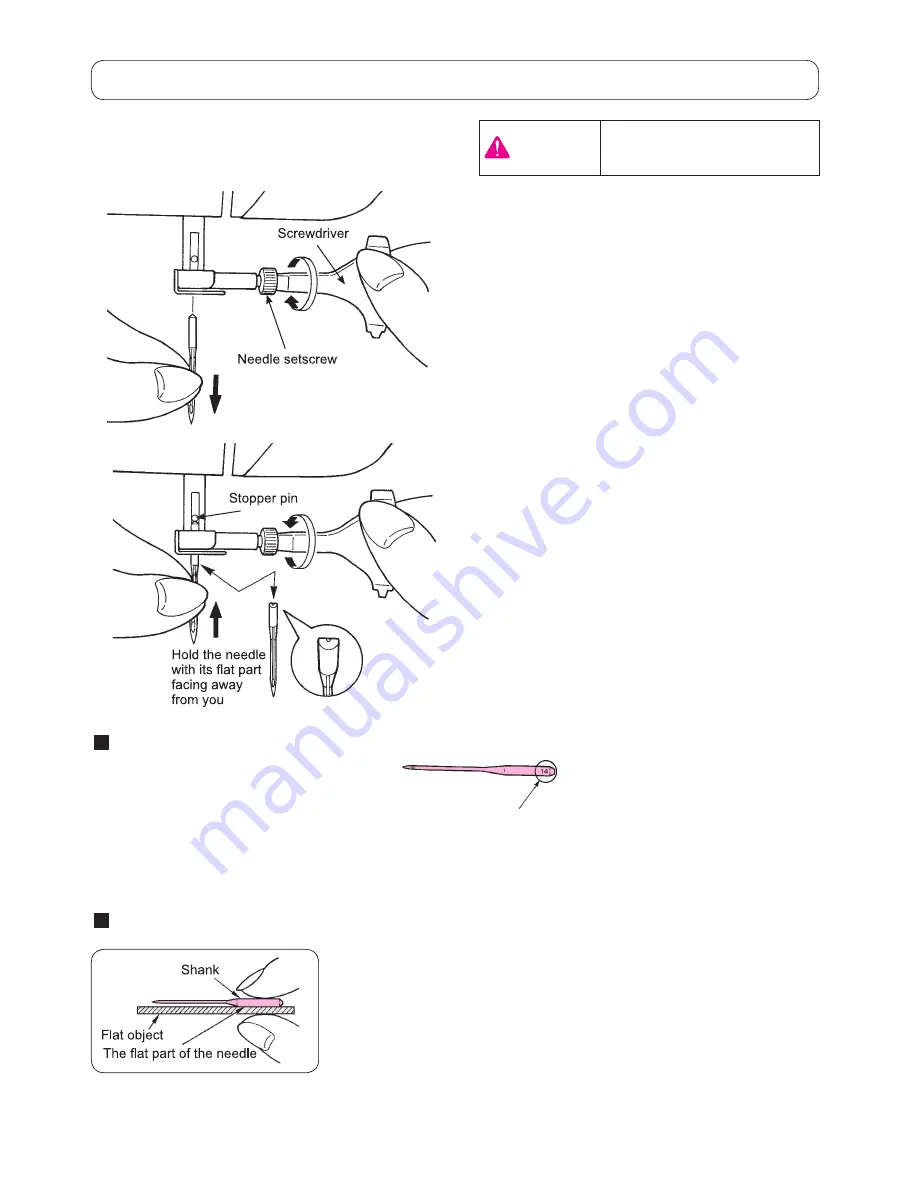

Attaching the needle

Needles to be purchased

When purchasing spare needles,

specify HA X 1 (130/705H) or

HA X 1 SP (needle for knits) .

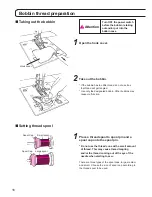

Checking the needle

Check the needle for its straightness occasionally.

Any bent needle would cause skipped stitches,

thread breakage or damage to materials.

Flat object

The flat part of the needle

Shank

Needle setscrew

Stopper pin

Hold the needle

with its flat part

facing away

from you

The machine will not sew if the needle is not inserted

correctly and/or a bent needle is used. It will cause

damage to the machine.

1

Removing needle

1. Turn the hand wheel towards you until the needle

comes to the highest position and lower the presser

foot.

2. Turn the needle setscrew towards you 1-2 times and

remove the needle.

2

Attaching the needle

(The needle cannot be inserted unless it

is correctly positioned.)

Hold the needle with its flat part facing away from you,

and insert it fully until it touches the stopper pin.

Securely tighten the needle setscrew.

Attention:

Screwdriver

Warning

Turn OFF the power switch

before changing the needle.

Summary of Contents for HZL-600

Page 2: ......

Page 12: ...10 ...

Page 75: ...73 ...

Page 100: ...List of stitch patterns 97 F600 Patterns for crazy quilt 98 ...

Page 101: ...Pattern for elongation 98 Letters numbers signs One point 99 ...

Page 102: ...List of stitch patterns 99 F400 100 ...

Page 103: ...100 One point Pattern for elongation Letters numbers signs 101 ...

Page 104: ...List of stitch patterns 101 F300 102 ...

Page 105: ...102 One point Pattern for elongation Letters numbers signs 103 ...

Page 107: ......