Operating noise of the machine

is dramatically reduced

The strokes of the right and

left thread take-up are

separately adjustable

The adjustment range of the

needle thread tension is widened

●

The operating noise produced by the

hook and thread take-up lever is

substantially reduced.

With its decreased noise level and

improved sound quality, the machine

offers a comfortable work environment

that reduces operator fatigue.

●

The improved opener reduces the

impact against the bobbin. By reducing

variations of bobbin thread tension

caused by the opener, irregular stitches

are eliminated.

The machine has two thread take-up guides,

one for the right thread and the other for the

left thread. As a result, the strokes of the

right and left thread take-ups are separately

adjustable. When the right and left portions

of the material differ in thickness, the

strokes of the thread take-up can be

accurately adjusted for the right and left

threads. With this capability, the machine

delivers consistently improved seam quality.

●

The needle tension controller has been

changed to the 1-needle, lockstitch type.

The style of the thread take-up spring

has been modified not only to allow the

spring to work more effectively, but also

to widen the needle thread adjustment

range compared with that possible with

the conventional thread take-up spring.

The thread tension can be easily

adjusted when changing the material to

be sewn. In addition, the thread tension

is further stabilized even when sewing

under a lower thread tension.

●

To downsize the design, the thread take-

up spring is integrated with the tension-

regulating knob. As a result, these parts

project out less from the machine, opening

up a clearer view of the area around the

needle entry for easier operation. In

addition, the machine offers easier

threading of the needle as compared with

the conventional machine head.

●

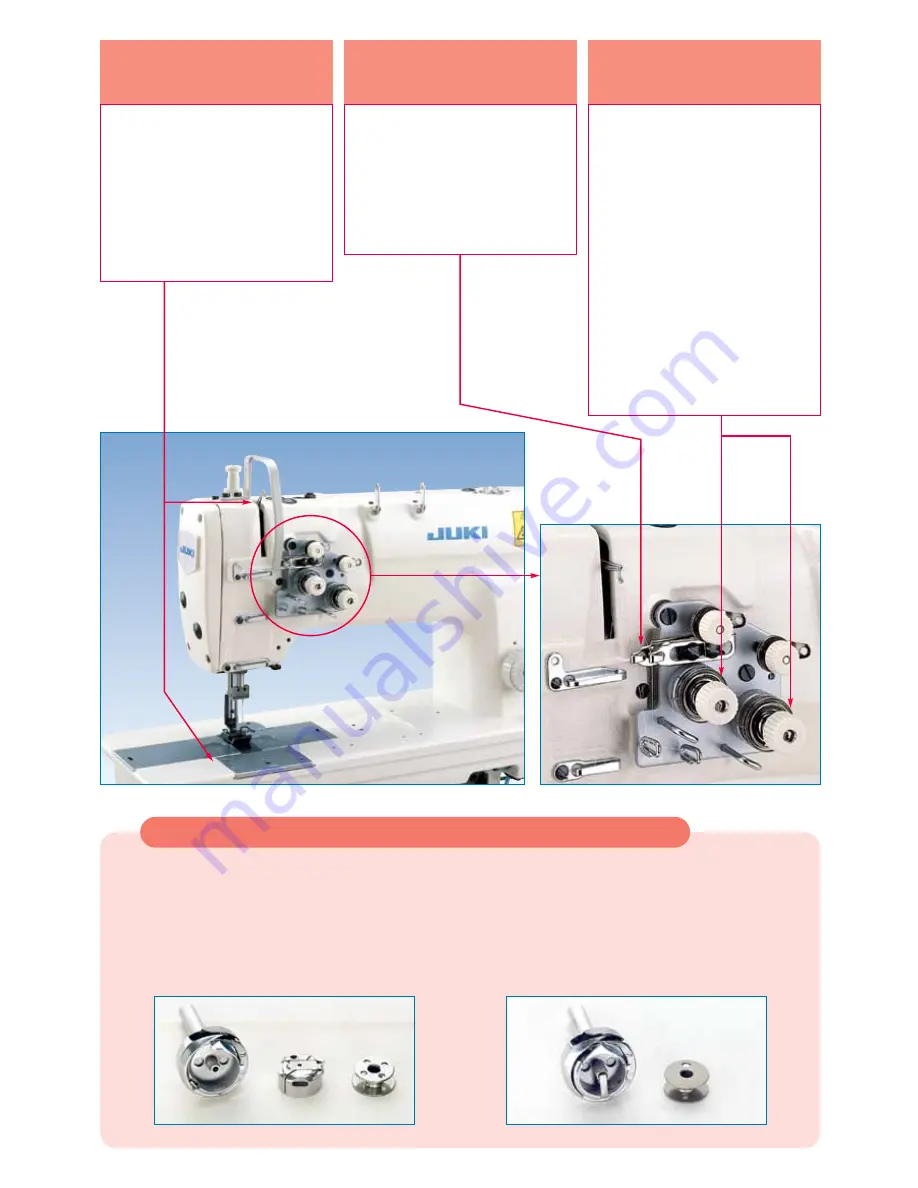

One available model is equipped with a newly developed a hook

that uses a non-rotational bobbin for the vertical-axis hook. For

the hook with a non-rotational bobbin, the bobbin is secured in

the bobbin case and does not rotate as the bobbin thread feeds.

This prevents variations in thread tension caused by changes in

the amount of remaining bobbin thread and idling of the bobbin.

With this hook and bobbin, the machine is able to use the full

amount of bobbin thread and sew consistent with a lower thread

tension compared with that used with the conventional hook.

●

The machine type provided with a latch hook is also available.

Select the type that fits your purpose.

(The latch hook is exclusively designed for the LH-3126F.

However, the conventional bobbin can be used with the latch

hook.)

Hook with a non-rotational bobbin

Specific latch hook

Hook

Hook

Bobbin case

Bobbin

Bobbin

The machine is equipped with a hook that uses a non-rotational bobbin