Hook part

Oiling

Oil

tank

Circulation filter

4

Two selectable new-method

oiling mechanisms

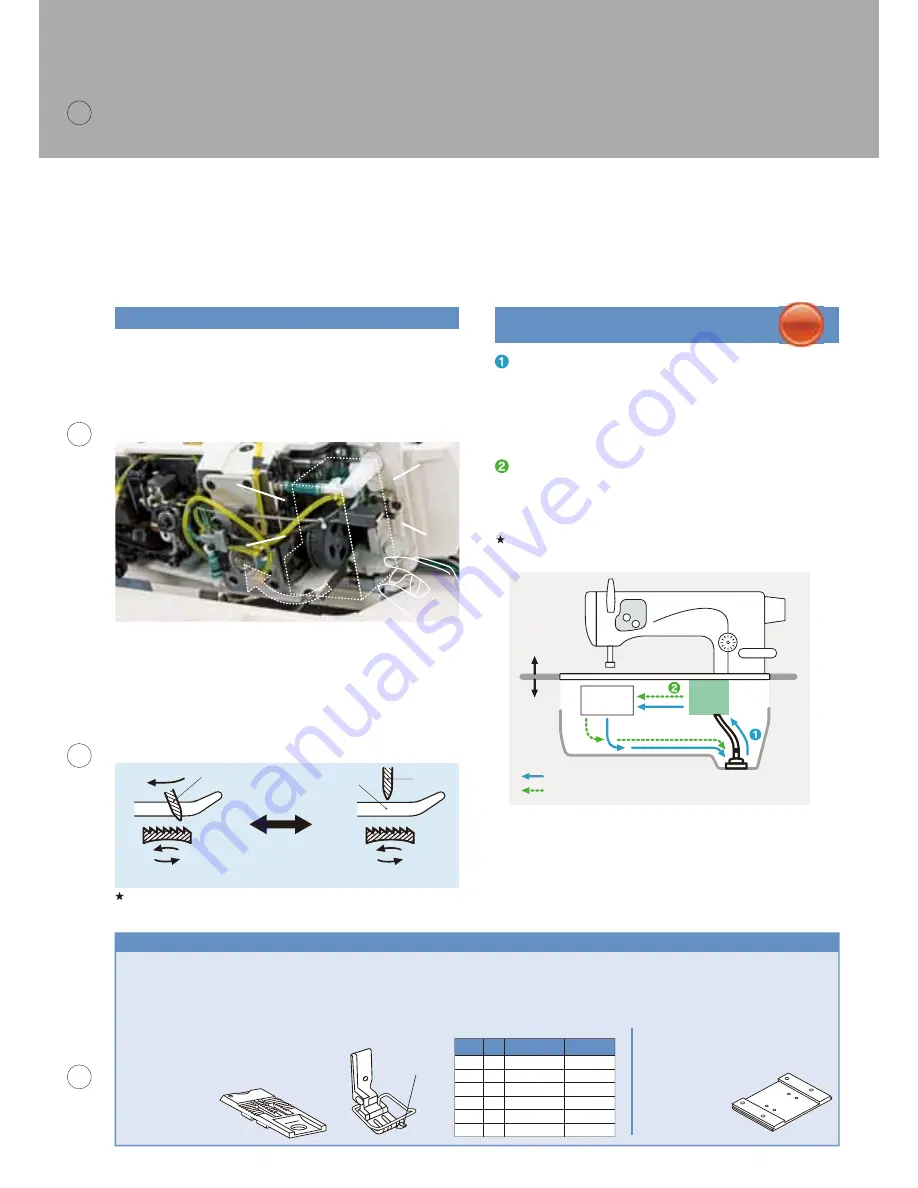

The oil dropped from the hook and its surrounding sections into

the under-cover is filtered to remove dirt and dust and is then

returned to the oil tank. This method saves the effort of oiling and

reduces oil consumption.

The oil dropped from the hook and its surrounding sections into

the under-cover is not returned to the oil tank, but only clean oil is

supplied to the hook at all times.

The feed method can be easily changed over

The location of the oil tank has been changed to the inside of the

sewing machine through our re-investigation of the lubricating

method. As a result, space is secured under the bed surface to

facilitate changeover of the feed method between the "needle

feed" and "bottom feed" and changeover of the feed timing

(re-placement of the timing belt).

For the process of sewing light-weight materials or the like,

puckering has to be prevented. In this case, the feed method can

be changed over to the bottom feed through an easy adjustment

and change of the gauge. In comparison with the needle feed, the

bottom feed works to prevent puckering and enables sewing with

a lower thread tension.

Eco-oil method

Clean oil method

The oiling method can be changed over as desired.

Gauge for tape attaching

(corresponding attachment classification code "T" for tape attaching; LH-3528A-F: Only the sewing machine for foundation)

Throat plate for tape attaching

The throat plate is designed with a

hollow on the side facing the

operator. This hollow

helps smooth

the feeding of tape.

Gauge for tape attaching (corresponding attachment classification code "T" for tape attaching; LH-3528A-F: Only the sewing machine for

foundation) The sewing machine is provided as standard with the gauge for tape attaching which is best-suited to the process for attaching tape to

foundation. The gauge for tape attaching consists of the throat plate for tape attaching, presser foot with guide and bed slide. The sewing machine

with the standard gauge can be changed to the tape attaching type sewing machine by changing the gauge with the gauge for tape attaching.

This reduces the

height when the

tape-attaching

holder is fixed on

the machine.

The LH-3528A supports, as standard, the feed type change-over function between

the needle feed and bottom feed.the feed type change-over function between the

needle feed and bottom feed. Contact JUKI for information on the models other than the LH-3528A.

Needle

Needle-feed

Changeover

Bottom-feed

Presser foot

Needle

The internal mechanism of the sewing machine has been thoroughly re-investigated to achieve

further improvement of maintainability and workability. JUKI does not cut corners on the quality

of those parts which are normally invisible, such as in the internal section of the sewing

machine. This represents JUKI's craftsmanship.

Changeover between the needle feed and

bottom feed

◎

Eco-oil method (circulation type)

Clean oil method

Dry

Oiling

Unique

to

JUKI

Guide presser

Slide plate (this side) :

Part No. 23206709

Part No.

Guide

inch mm

Throat plate for

tape attaching

Guide presser

1/8

3/16

7/32

1/4

9/32

5/16

3.2

4.8

5.6

6.4

7.1

7.9

22628002

22628200

22628309

22628408

22628507

22628606

22647051

22647150

22647259

22647358

22647457

22647556