– 100 –

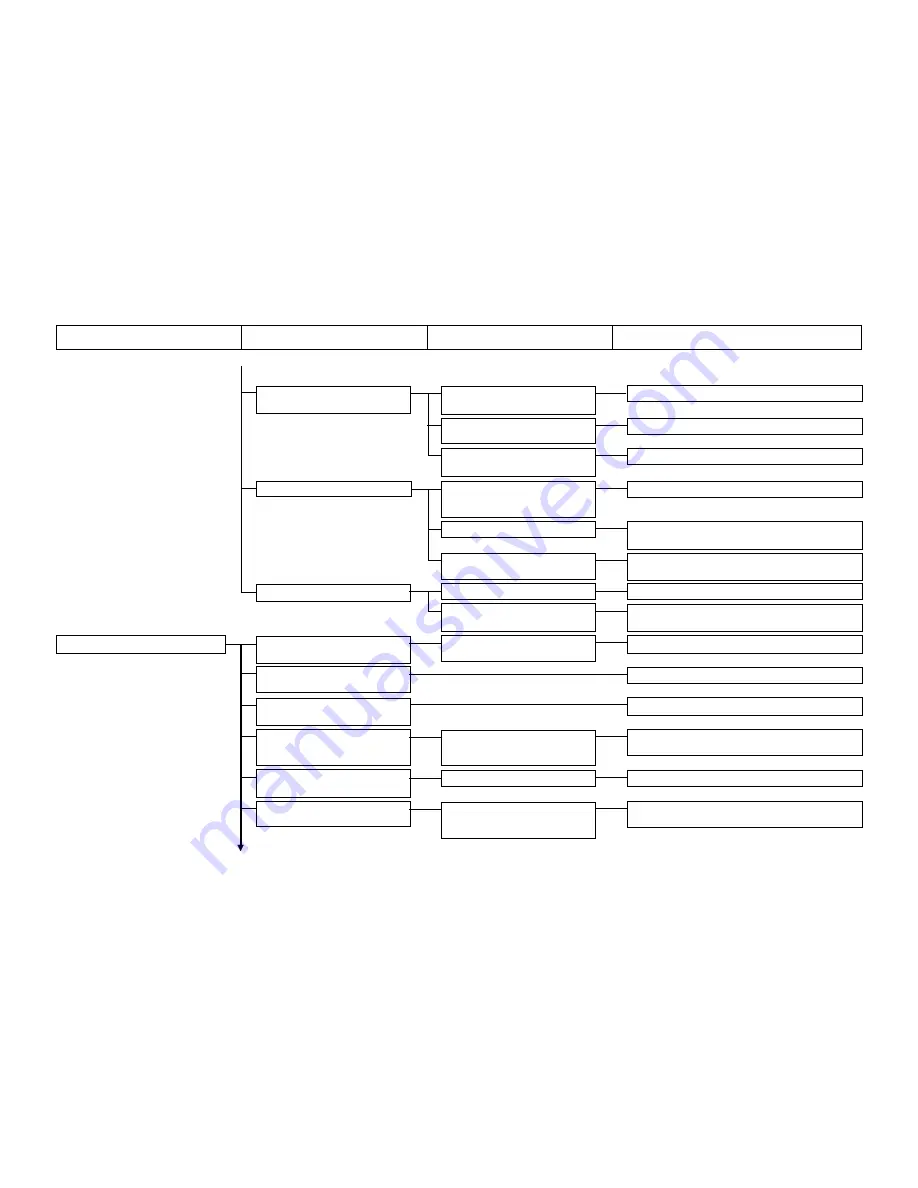

6-3) Moving knife does not spread

3-A) Initial position of the moving

Adjust the initial position of the moving knife.

threads.

knife is maladjusted.

3-B) Thread trimmer cam position

Adjust the thread trimmer cam position.

is inadequate.

3-C) Position of the shuttle upper

Adjust the position of shuttle upper spring .

spring is defective.

6-4) Stitch skipping at the final stitch

4-A) Timing of the needle to the

Adjust the timing and the clearance.

inner hook and the clearance

between them are defective.

4-B) Work clamp foot big.

Let the biginning of stitch come closer to the presser

by moving the pattern.

4-C) Loop of the needle thread

Attach the needle with the long groove orienting

falls down.

slightly to the right (approximately 20

°

)

6-5) Bobbin thread cannot be cut.

5-A) Bobbin thread tension is low.

Streng then the bobbin thread tension.

5-B) Needle hole size of the needle

Replace the needle hole guide with a new one having

hole guide is large.

a smaller hole diameter.

7. Poorly tense stitches

7-1) Tension controller No. 2 is

1-A) Tension of the tension controller

Properly adjust the tension of tension controller No. 2.

maladjusted.

No. 2 is low.

7-2) Tension controller No. 2 is

Adjust the thread tension releasing mechanism.

floating.

7-3) Thread take-up spring is

Adjust thread take-up spring tension and stroke.

maladjusted.

7-4) Clearance between the inner

4-A) The clearance between the

Properly adjust the clearance of inner hook and

hook and the shuttle driver is

inner hook and the shuttle

shuttle driver.

defective.

driver is too small.

7-5) Selection of the needle to be

5-A) Needle to be used is thin.

Replace the needle with a thicker one.

used is improper.

7-6) Selection of the needle hole

6-A) Hole diameter of the needle

Replace the needle hole guide with a new one having

guide is improper.

hole guide to the needle to be

a larger needle hole.

used and thread is small.

Trouble

Cause (1)

Cause (2)

Check and corrective measures

From the previous page

To the next page

Summary of Contents for LK-1900A

Page 20: ... 16 10 Hook adjustment Standard Adjustment 0mm 0mm 7 5mm 0 05 0 1mm For DPX5 For DPX17 ...

Page 90: ... 86 Grease Grease Grease Grease Grease 8 Needle thread clamp mechanism area ...

Page 91: ... 87 Grease Grease A Grease Grease Grease Grease 9 LK 1901A relations ...

Page 92: ... 88 10 LK 1903A relations Grease Grease ...

Page 114: ... 111 12 Circuit diagrams 1 Block diagram A ...

Page 115: ... 112 2 Power supply circuit diagram A ...

Page 116: ... 113 3 Power supply circuit diagram B ...

Page 117: ... 114 4 Power supply circuit diagram C ...

Page 118: ... 115 5 Servo motor circuit diagram ...

Page 119: ... 116 6 Sensor pedal VR circuit diagram ...

Page 120: ... 117 7 MAIN PANEL board circuit diagram ...

Page 121: ... 118 8 Motor solenoid circuit diagram Thread trimmer Lifting the work clamp foot motor ...