– 28 –

(20) AT unit connection / disconnection

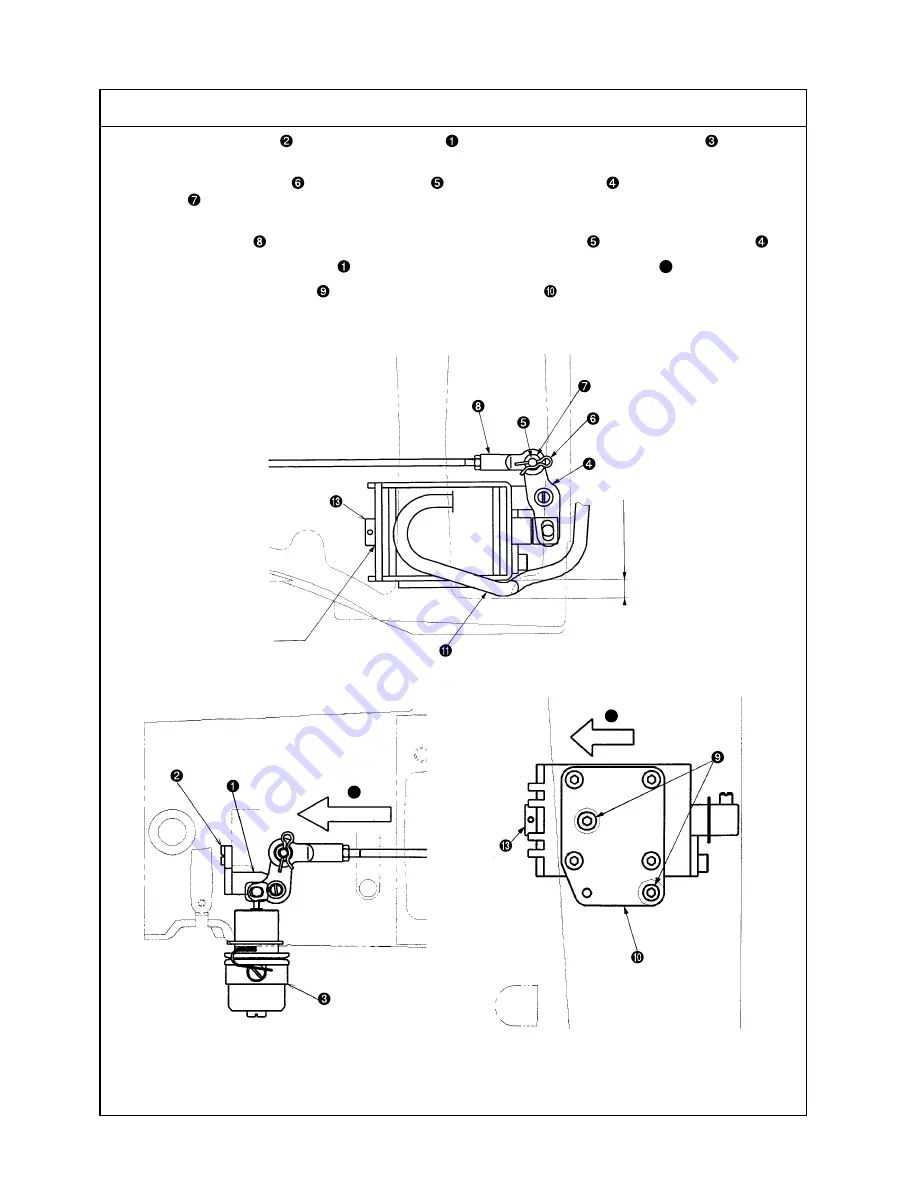

Procedures of disassembling /assembling

1. Remove the set screw

of the AT link unit (front)

and take out the second thread tension

. ((19) Refer

to “Second thread tension connection / disconnection.”)

2. Draw out the cotter pin

from the pin block

of the AT link unit (rear)

. Be careful not to drop the

washer

at that time.

* Work becomes easier if the main shaft motor is removed.

3. Lift the joint block

of the AT unit upwards and take it off the pin block

of the AT link unit (rear)

.

4. Draw out the AT link unit (front)

from the plane side (in the direction of the arrow

E

) and remove it.

5. Remove the two set screws

and take out the AT solenoid unit

.

6. For reassembly, follow the steps of 5. to 1. above.

E

F

Close contact

Solenoid side

Summary of Contents for LK-1900A

Page 20: ... 16 10 Hook adjustment Standard Adjustment 0mm 0mm 7 5mm 0 05 0 1mm For DPX5 For DPX17 ...

Page 90: ... 86 Grease Grease Grease Grease Grease 8 Needle thread clamp mechanism area ...

Page 91: ... 87 Grease Grease A Grease Grease Grease Grease 9 LK 1901A relations ...

Page 92: ... 88 10 LK 1903A relations Grease Grease ...

Page 114: ... 111 12 Circuit diagrams 1 Block diagram A ...

Page 115: ... 112 2 Power supply circuit diagram A ...

Page 116: ... 113 3 Power supply circuit diagram B ...

Page 117: ... 114 4 Power supply circuit diagram C ...

Page 118: ... 115 5 Servo motor circuit diagram ...

Page 119: ... 116 6 Sensor pedal VR circuit diagram ...

Page 120: ... 117 7 MAIN PANEL board circuit diagram ...

Page 121: ... 118 8 Motor solenoid circuit diagram Thread trimmer Lifting the work clamp foot motor ...