– 1 –

1. Specifications

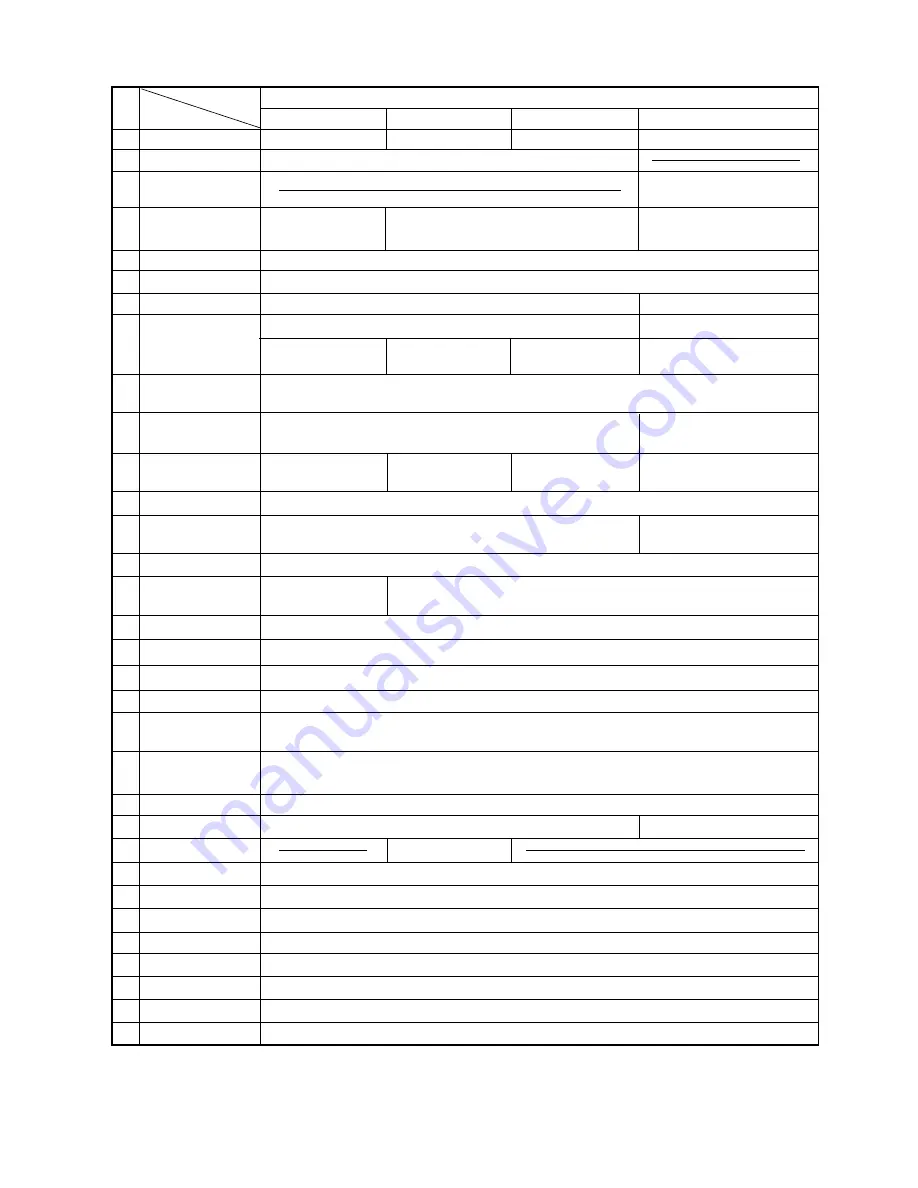

No.

Application

LK-1900A

LK-1901A

LK-1902A

LK-1903A

1

Application

Bartacking

Eyelet buttonhole bartacking

Belt-loop attaching

Lock stitch button sewing

2

Sewing area

X-Direction (right, left) 40mm; Y-Direction (forward, backward) 30mm

3

Button size

Type: Round-shaped, flat button

ø 8 to ø32mm, Standard (ø8 to ø20mm)

4

Max. sewing

* 3000rpm max.

* 3000rpm max.

* 2700rpm max.

speed

5

Stitch length

0.1mm to 10.0mm (adjustable in 0.1mm step)

6

Feed motion of work clamp foot

intermittent feed (2-shaft drive by stepping motor)

7

Meddle bar stroke

41.2mm

45.7mm

8

Needle

DPX5 #14

DPX17 #14

DPX5#11 (F, M)

(DPX17#21

(DPX17#21 heavy-weight material)

heavy-weight material)

9

Work clamp lifting

Pulse motor

system

10

Lifting (lift) amount

Standard 14mm, Max.17mm (In the reverse-rotation needle-up

Max. 13mm

of work-clamp foot

function)

11

Number of standard

50 patterns

3 patterns

6 patterns

50 patterns

patterns

12

Wiper system

Interlockly with work clamp foot lifter by pulse motor

13

Needle thread

Standard: General 0

Standard: Disable 1

clamp device

(Caution) 1.

14

Needle thread tension

Active tension (electronic thread tension control mechanism)

15

Hook

Standard semi-rotary hook

Standard semi-rotary hook

(2-fold semi-rotary hook)

16

Lubrication

Hook : minute-quantity lubrication

17

Lubricating oil

JUKI NEW Defrix oil (equivalent to ISO VG32) (Lubrication system)

18

Grease

1. Penetration No. 2 lithium grease, 2. Templex N2, 3. Juki Grease A, 4. Juki Grease B (Caution)2.

19

Memory medium

EEP-ROM (128Kbyte) EP-ROM (32Kbyte)

20

Number of stitches that

Max. 20,000 stitches

can be stored in memory

21

Enlarging/Reducing

X-Direction, Y-Direction: 20 ~ 200% each (1% step)

facility

22

Enlarging/Reducing method

Pattern enlargement/reduction can be done by increasing/decreasing the stitch length

23

Sewing speed limits

450 ~ 3000rpm (100rpm step) (2700rpm max. for the 2-fold semi-rotary hook) 400 ~ 2700rpm (100rpm step)

24

Material clrawing amount

Max. 3mm

25

Pattern selector facility

Pattern No. designation system (1 ~ 200)

26

Bobbin thread counter

Up/Down method (0~9999)

27

Sewing machine motor

450W compact AC servomotor (direct-drive system)

28

External dimensions

W: 1200mm, L: 660mm, H: 1100mm (standard table stand applied)

29

Weight

Machine head (include motor): 42kg, Control box: 16.5kg

30

Power consumption

320W

31

Working temperature range

5

°

C~35

°

C

32

Working humidity range

35% ~ 85% (no dew condensation permissible)

* Maximum sewing speed should be reduced according to the sewing conditions.

(Caution) 1. LK-1903A is set to needle thread clamp prohibited (no motion) with memory switch No. 35 at

the time of standard delivery.

2. Grease type, refer to (3) Greasing parts of [9] Maintenance.

Model name

Item

(When sewing pitches are less than 5mm in

X-direction and 3.5mm in Y-direction)

(*2700rpm fo the

2-fold semi-rotary hook)

Summary of Contents for LK-1900A

Page 20: ... 16 10 Hook adjustment Standard Adjustment 0mm 0mm 7 5mm 0 05 0 1mm For DPX5 For DPX17 ...

Page 90: ... 86 Grease Grease Grease Grease Grease 8 Needle thread clamp mechanism area ...

Page 91: ... 87 Grease Grease A Grease Grease Grease Grease 9 LK 1901A relations ...

Page 92: ... 88 10 LK 1903A relations Grease Grease ...

Page 114: ... 111 12 Circuit diagrams 1 Block diagram A ...

Page 115: ... 112 2 Power supply circuit diagram A ...

Page 116: ... 113 3 Power supply circuit diagram B ...

Page 117: ... 114 4 Power supply circuit diagram C ...

Page 118: ... 115 5 Servo motor circuit diagram ...

Page 119: ... 116 6 Sensor pedal VR circuit diagram ...

Page 120: ... 117 7 MAIN PANEL board circuit diagram ...

Page 121: ... 118 8 Motor solenoid circuit diagram Thread trimmer Lifting the work clamp foot motor ...