– 57 –

6. Press the key and define the test program number.

7. For each program, the test program can be closed when the key is pressed.

The condition of 5. recovered.

However, the continuous operation mode cannot be canceled if it is once as-

sumed. To close this mode, it is necessary to turn off the power supply.

6. Test mode

When the test mode is started, it is possible to carry out maintenance and inspection.

(1) Test mode start

1. When the key is continuously pressed for 3 seconds in the state that the

sewing LED is turn off, the buzzer sounds and test mode start can be selected,

with the user level setting mode of the memory switch kept effective.

(Caution) The test mode cannot be selected unless the key is pressed

for more than 3 seconds.

2. Change the memory switch No. with the , keys to select the test mode.

3. Press the key. The selected test mode is assumed and a display output

test can be started. In regard to the contents of the display output test, refer to

(2) Display output test.

4. Press the key. The display output test is finished and operation moves to

the selection of another test feature.

5. Select the test program No. by the use of the , keys.

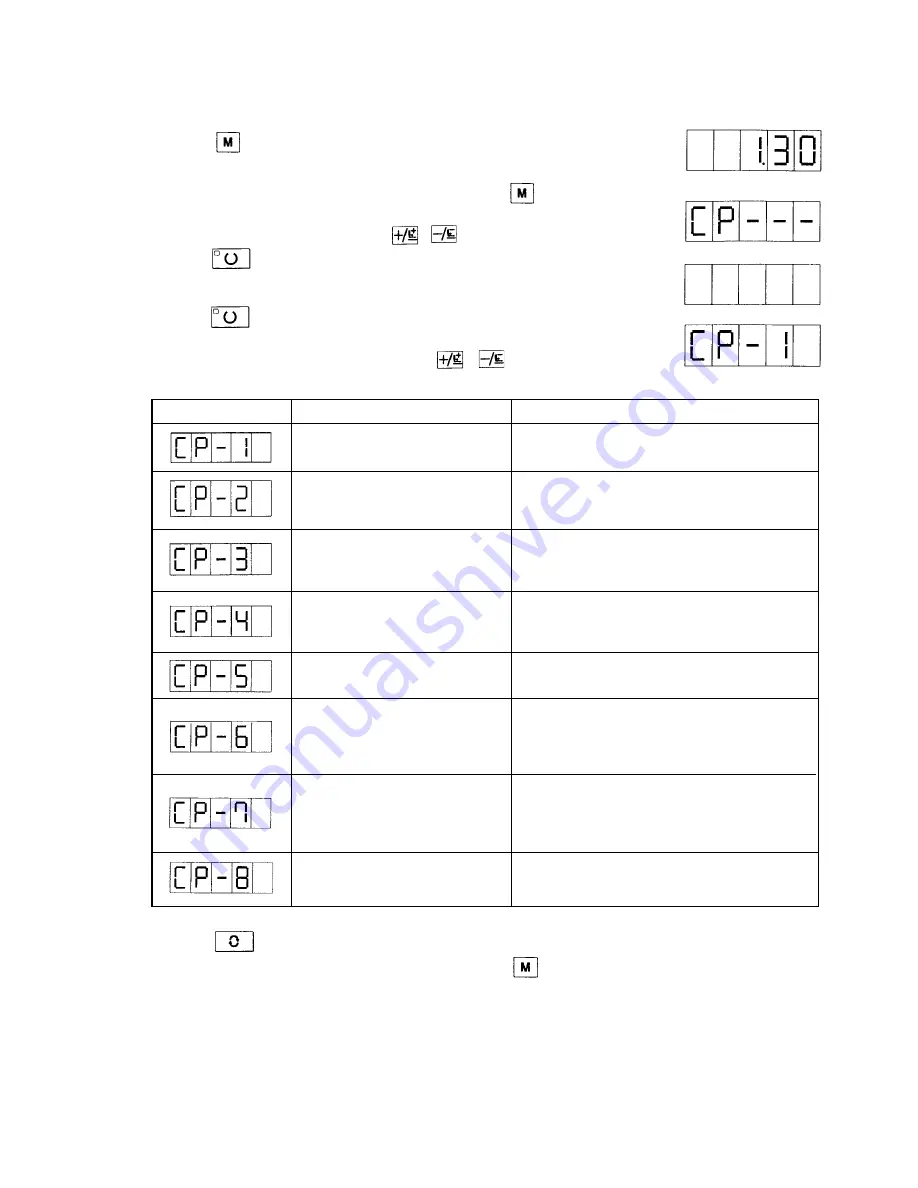

Test program No.

Test program

Descriptions

Input signal check

The conditions of switches and sensor inputs

are displayed at the LED.

XY motor / origin sensor check

Inching operation of the X/Y motor, operation

of origin retrieval, and the status of X/Y origin

sensors are displayed.

Continuous operation

After the setting of continuous operational con-

ditions, the continuous operation mode is as-

sumed.

Main motor rpm check

The sewing machine is started based on the

preset rpm, and the measured rpm number is

displayed.

Output check

Output is maintained for the LK1901A material

drawing magnet.

Presser foot and thread trimmer

Inching operation of the presser foot and thread

motor and origin sensor check

trimmer motor, operation of origin retrieval,

and the status of presser origin and presser sen-

sors are displayed.

Needle thread clamp motor and

Inching operation of the needle thread clamp motor,

origin sensor check

operation of origin retrieval, and the status of

needle thread clamp origin and needle thread

clamp sensors are displayed.

Software version display

The software versions of the MAIN and SDC

boards are displayed.

Summary of Contents for LK-1900A

Page 20: ... 16 10 Hook adjustment Standard Adjustment 0mm 0mm 7 5mm 0 05 0 1mm For DPX5 For DPX17 ...

Page 90: ... 86 Grease Grease Grease Grease Grease 8 Needle thread clamp mechanism area ...

Page 91: ... 87 Grease Grease A Grease Grease Grease Grease 9 LK 1901A relations ...

Page 92: ... 88 10 LK 1903A relations Grease Grease ...

Page 114: ... 111 12 Circuit diagrams 1 Block diagram A ...

Page 115: ... 112 2 Power supply circuit diagram A ...

Page 116: ... 113 3 Power supply circuit diagram B ...

Page 117: ... 114 4 Power supply circuit diagram C ...

Page 118: ... 115 5 Servo motor circuit diagram ...

Page 119: ... 116 6 Sensor pedal VR circuit diagram ...

Page 120: ... 117 7 MAIN PANEL board circuit diagram ...

Page 121: ... 118 8 Motor solenoid circuit diagram Thread trimmer Lifting the work clamp foot motor ...