– 66 –

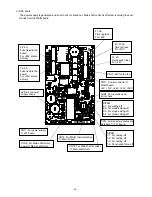

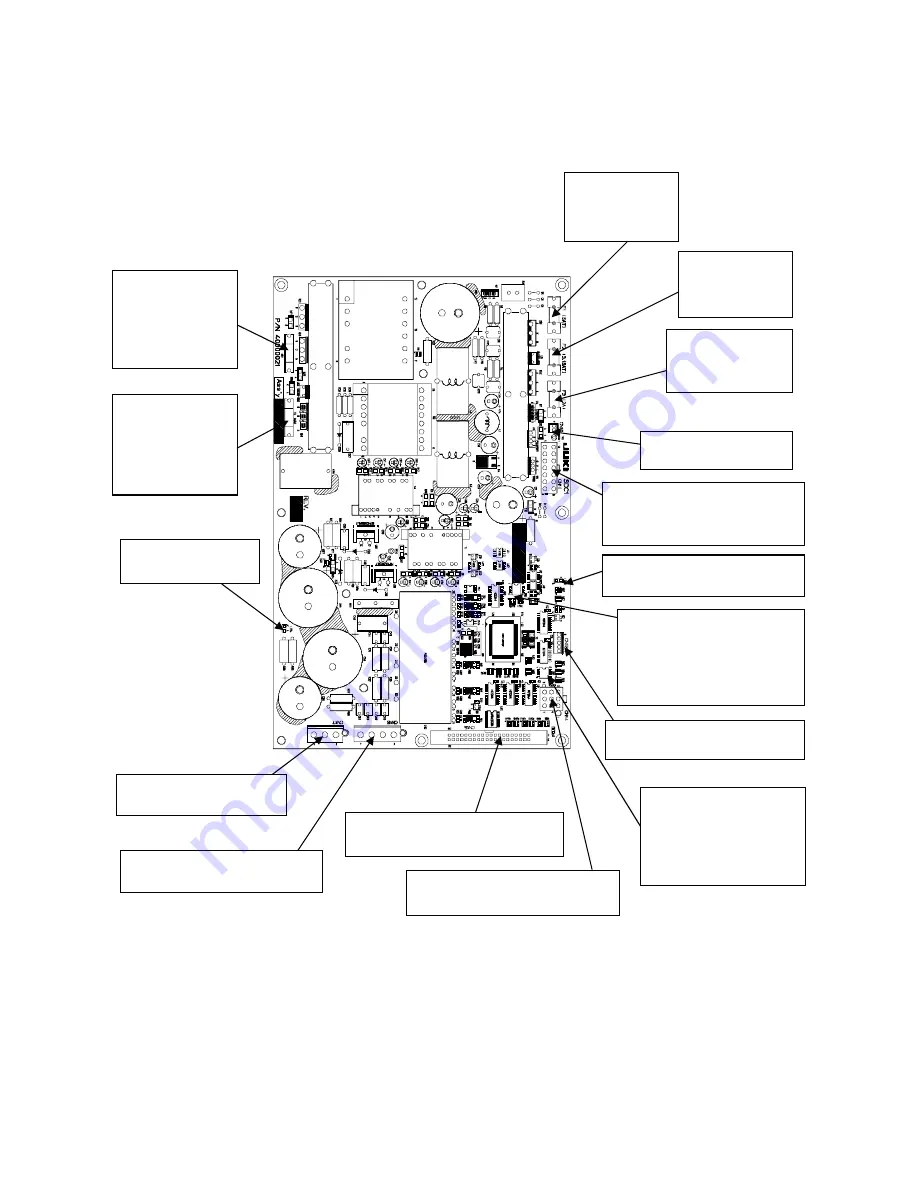

3) SDC board

The power supply is generated and error check is carried out. Main shaft control is effected, receiving the com-

mands from the MAIN board.

LED4: For power

supply check

LED3: For operation and

error check

CN10: 24V for the fan

F1: 5A

Time lag fuse

For +85V

F2: 3.15A

Time lag fuse

For +33V

F3: 2A

Quick-action fuse

For +24V

F4: 4A

Fuse fixed to the

board

For +85V source

primary

F5: 4A

Fuse fixed to the

board

For +33V source

primary

CN11: Power connector

→

MAIN board

+5V, +12V, +24V, +33V, +85V

DIPSW

2-1: For writing-off

2-2: For mode setting-off

2-3: For mode setting-off

2-4: For mode setting-off

DIPSW

1-1: For testing-off

1-2: For testing-off

1-3: For testing-off

1-4: Penetration force-off

CN17: For power supply

←

FLT board

CN16: For Main shaft motor

power

→

Main shaft motor

CN15: For MAIN communication

→

Main board

CN14: For Main shaft encoder

→

Main shaft motor

CN13: For momentary interruption

detection

←

FLT board

Summary of Contents for LK-1900A

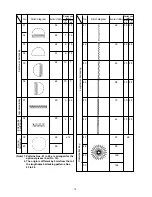

Page 20: ... 16 10 Hook adjustment Standard Adjustment 0mm 0mm 7 5mm 0 05 0 1mm For DPX5 For DPX17 ...

Page 90: ... 86 Grease Grease Grease Grease Grease 8 Needle thread clamp mechanism area ...

Page 91: ... 87 Grease Grease A Grease Grease Grease Grease 9 LK 1901A relations ...

Page 92: ... 88 10 LK 1903A relations Grease Grease ...

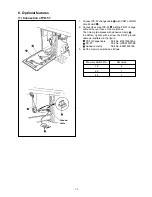

Page 114: ... 111 12 Circuit diagrams 1 Block diagram A ...

Page 115: ... 112 2 Power supply circuit diagram A ...

Page 116: ... 113 3 Power supply circuit diagram B ...

Page 117: ... 114 4 Power supply circuit diagram C ...

Page 118: ... 115 5 Servo motor circuit diagram ...

Page 119: ... 116 6 Sensor pedal VR circuit diagram ...

Page 120: ... 117 7 MAIN PANEL board circuit diagram ...

Page 121: ... 118 8 Motor solenoid circuit diagram Thread trimmer Lifting the work clamp foot motor ...