– 79 –

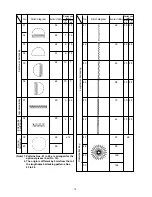

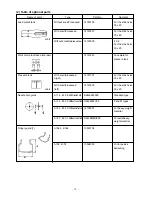

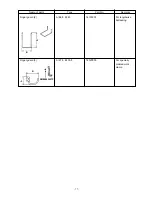

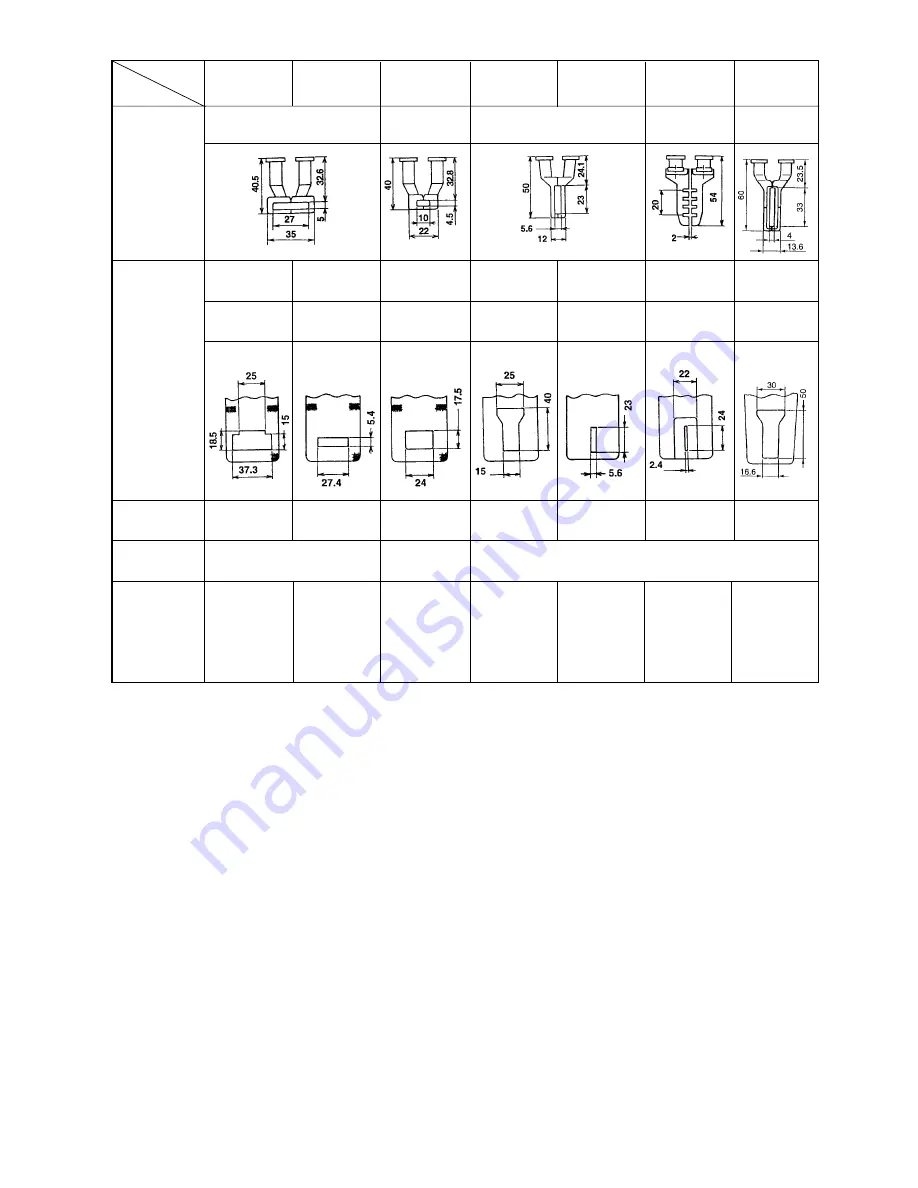

* Install a finger guard suitable for each work clamp foot when replacing the work clamp foot.

* The presser bar No. 12 (optional) should be used for the standard patterns Nos. 41 to 46 (lengthwise

bartacking).

6

7

8

9

10

11

12*

13548151 (asm.)

13542451 (asm.) 13571955 (asm.)

13561360 (asm.)

Work clamp foot

13548003

13554803

14116602

14116503

14116909

14116701

14137707

( Without knurl) ( Without knurl) ( Without knurl) ( Without knurl)

Feed plate

Sewing specification

S

H

S

F

F

F

F

* Finger guard

13548300

13533104

14135305

Remarks

Optional

Optional

Optional

Optional

Optional

14137509 (Right)

14137608 (Left)

Standard acces-

sory for H (heavy-

weight material)

type machine

head.

Standard acces-

sory for F (founda-

tion) type machine

head.

No. of the work

clamp foot

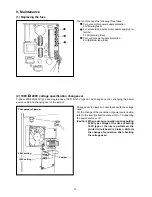

Summary of Contents for LK-1900A

Page 20: ... 16 10 Hook adjustment Standard Adjustment 0mm 0mm 7 5mm 0 05 0 1mm For DPX5 For DPX17 ...

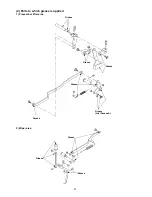

Page 90: ... 86 Grease Grease Grease Grease Grease 8 Needle thread clamp mechanism area ...

Page 91: ... 87 Grease Grease A Grease Grease Grease Grease 9 LK 1901A relations ...

Page 92: ... 88 10 LK 1903A relations Grease Grease ...

Page 114: ... 111 12 Circuit diagrams 1 Block diagram A ...

Page 115: ... 112 2 Power supply circuit diagram A ...

Page 116: ... 113 3 Power supply circuit diagram B ...

Page 117: ... 114 4 Power supply circuit diagram C ...

Page 118: ... 115 5 Servo motor circuit diagram ...

Page 119: ... 116 6 Sensor pedal VR circuit diagram ...

Page 120: ... 117 7 MAIN PANEL board circuit diagram ...

Page 121: ... 118 8 Motor solenoid circuit diagram Thread trimmer Lifting the work clamp foot motor ...