– 93 –

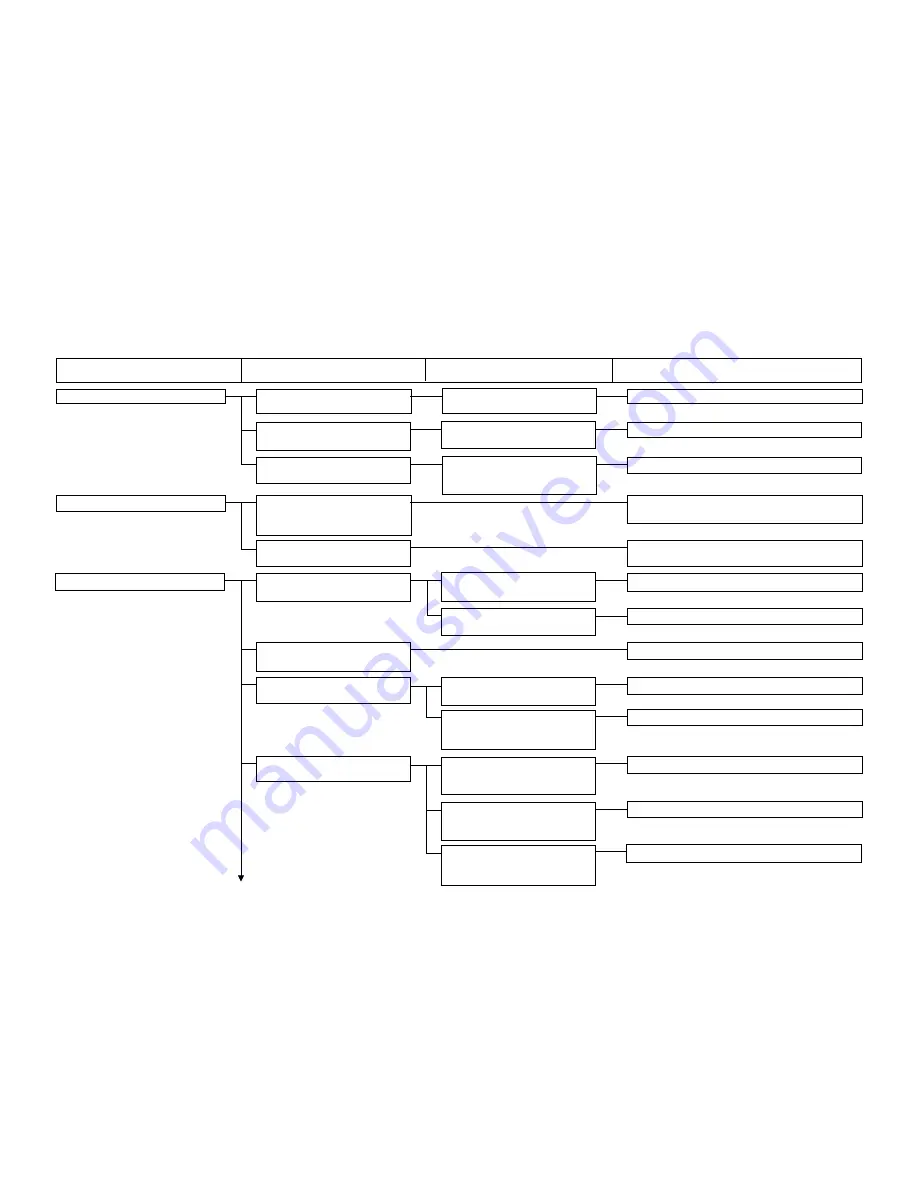

1. Wiper cannot spread a thread

1-1) Interference between wiper

1-A) Wiper mounting position is

Adjust the wiper position.

and needle

inadequate.

1-2) Displacement of front-rear

2-A) Wiper mounting position is

Adjust the wiper position.

wiper position

inadequate.

1-3) Thread holding before wiper

3-A) The right left wiper mounting position

Adjust the wiper position

action

is inadequate. (insufficient

distance to the needle).

2. Abnormal noise

2-1) Backlash between the oscillator

Check oscillator gear positioning and adjust the

and the shuttle driver shaft is

lower shaft gear backlash.

large.

2-2) Too much clearance between

Adjust the clearance between the shuttle and the

shuttle and shuttle driver

shuttle driver.

3. Deformation in sewn patterns

3-1) Too much backlash in the

1-A) Backlash is too much in the

Adjust backlash of motor base.

Y feed gear

Y feed arm and the motor base.

1-B) Backlash is too much in the Y feed

Adjust backlash of Y feed pulse motor.

pulse motor and the motor base.

3-2) Too much backlash in the

Adjust backlash of the X feed gear.

X feed gear

3-3) Travelling torque in X direction

3-A) The motor is pressed against

Adjust backlash of the motor.

is excessive.

the X feed arm too strongly.

3-B) The feed plate or the work

Tighten the set screw further for the needle hole guide.

clamp foot is caught by the

needle hole guide.

3-4) Travelling torque in Y direction

4-A) The pulse motor is pressed

Adjust backlash of the feed motor gear.

is excessive.

against the Y feed shaft too

strongly.

4-B) Friction is excessive between

Install the cloth feed support plate.

the Y feed arm and the cloth

feed support plate.

4-C) The feed plate or the work

Tighten the set screw further for the needle hole guide.

clamp foot is caught by the

needle hole guide.

Trouble

Cause (1)

Cause (2)

Check and corrective measures

11. Troubles and corrective measures

(1) Troubles and corrective measures (Mechanical parts)

To the next page

Summary of Contents for LK-1900A

Page 20: ... 16 10 Hook adjustment Standard Adjustment 0mm 0mm 7 5mm 0 05 0 1mm For DPX5 For DPX17 ...

Page 90: ... 86 Grease Grease Grease Grease Grease 8 Needle thread clamp mechanism area ...

Page 91: ... 87 Grease Grease A Grease Grease Grease Grease 9 LK 1901A relations ...

Page 92: ... 88 10 LK 1903A relations Grease Grease ...

Page 114: ... 111 12 Circuit diagrams 1 Block diagram A ...

Page 115: ... 112 2 Power supply circuit diagram A ...

Page 116: ... 113 3 Power supply circuit diagram B ...

Page 117: ... 114 4 Power supply circuit diagram C ...

Page 118: ... 115 5 Servo motor circuit diagram ...

Page 119: ... 116 6 Sensor pedal VR circuit diagram ...

Page 120: ... 117 7 MAIN PANEL board circuit diagram ...

Page 121: ... 118 8 Motor solenoid circuit diagram Thread trimmer Lifting the work clamp foot motor ...