Juki Corporation operates an environmental management system

to promote and conduct the following as the company engages in

the research, development, design, sales, distribution,and

maintenance of industrial sewing machines, household sewing

machines, industrial robots, etc., and in the provision of sales and

maintenance services for data entry systems:

(1) The development of products and engineering processes

that are safe to the environment

(2) Green procurement and green purchasing

(3) Energy conservation (reduction in carbon-dioxide emissions)

(4) Resource saving (reduction of papers purchased, etc.)

(5) Reduction and recycling of waste

(6) Improvement of logistics efficiency (modal shift and

improvement of packaging, packing, etc.)

SEWING MACHINERY BUSINESS UNIT

DECEMBER, 2013 Printed in Japan(C)

2-11-1

, TSURUMAKI, TAMA-SHI,

TOKYO

206-8551

, JAPAN

PHONE : (81) 42-357-2254

FAX : (

81

) 42-357-2274

http://www.juki.com

Specifications and appearance are subject to change without prior notice for improvement.

Read the instruction manual before putting the machine into service to ensure safety.

This catalogue prints with environment-friendly soyink on recycle paper.

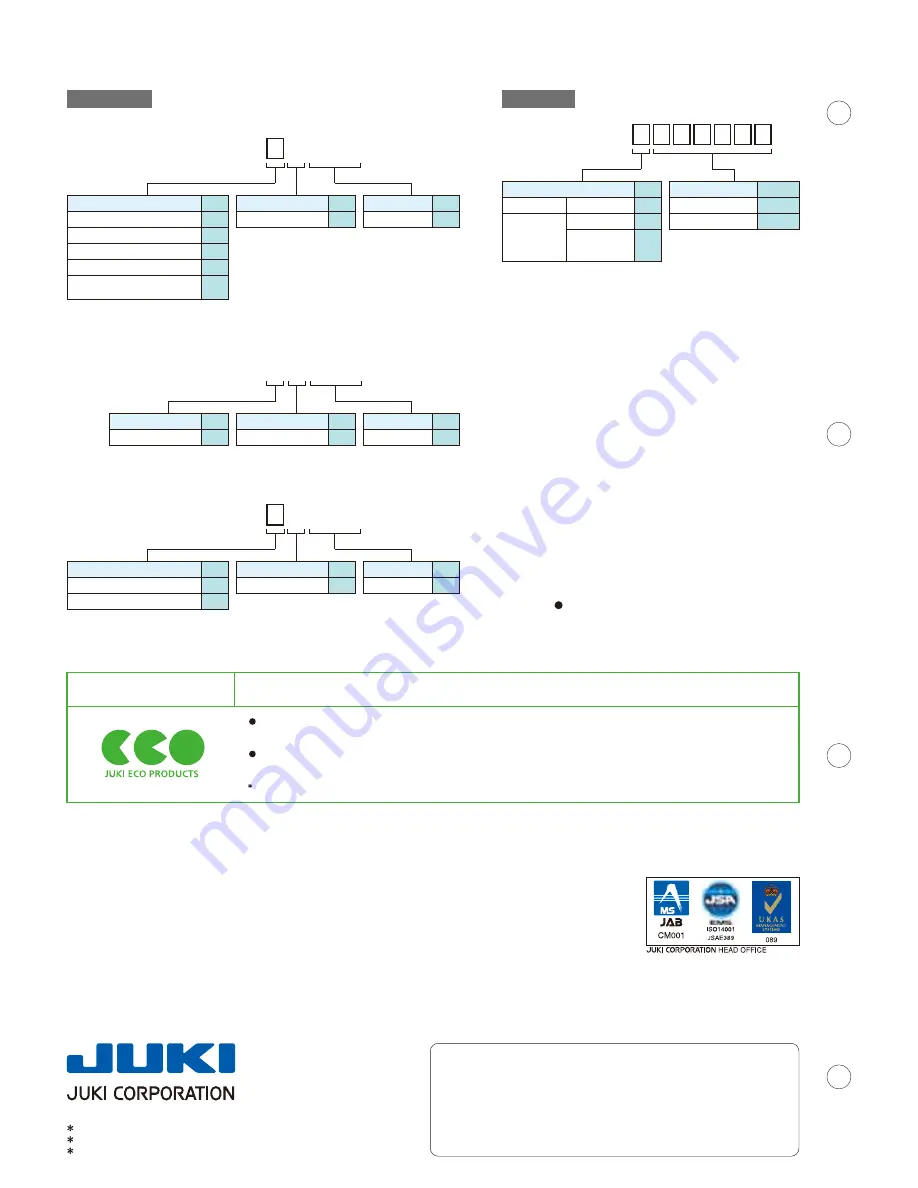

Machine head

Control box

Code

Work clamp foot

S

Standard

Code

Attachment

000

Not provided

Code

Work clamp foot

S

Standard

Code

Attachment

000

Not provided

Code

Application

S

Standard

H

For heavy-weight materials

F

For foundation

M

For knits and knitted materials

W

With large hook

for heavy-weight materials

Code

Operation panel

SS

Standard panel

IP420U

Option panel

WHEN YOU PLACE ORDERS

Please note when placing orders, that the model name should be written as follows:

To order, please contact your nearest JUKI distributor.

L K 1 9 0 0 B S 0 0 0

Code

Application

S

Standard

H

For heavy-weight materials

Code

Power supply

E

3-phase

K

N

Single-phase

200~240V

200~240V

CE 200~240V

(not provided with

power switch)

Code

Work clamp foot

S

Standard

Code

Attachment

000

Not provided

L K 1 9 0 2 B S 0 0 0

Code

Application

S

Standard

L K 1 9 0 1 B S S 0 0 0

M C 6 7 0

Bartacking

Eyelet buttonhole bartacking

Belt-loop attaching

J U K I E C O P R O D U C T S

The LK-1900B Series is an eco-friendly product which complies with

JUKI ECO PRODUCTS standards for protecting the environment

The RoHS Directive is an EU Directive limiting the use of 6 hazardous substances (lead, hexavalent chromium, mercury, cadmium, PBB and PBDE) in electrical and electronic equipment.

The Juki Green Procurement Guideline is the voluntarily established criteria to eliminate not only the aforementioned six substances, but also other ones which also adversely affect the environment.

For details of JUKI ECO PRODUCTS, refer to: http://www.juki.co.jp/eco_e/index.html

This sewing machine reduces power consumption by 15% as compared with the conventional models.

The sewing machine complies with the "Juki Group Green Procurement Guidelines" on the use of

hazardous substances, which is stricter than other restrictions, such as those of the RoHS Directive.