– 35 –

1.

Remove the belt from the hand-wheel on the machine head.

2.

Remove the pulley cover from the motor, and then, remove the

belt.

3.

Turn ON the power switch.

4.

Set the stitch dial

to the maximum value (P=9) on the scale.

5.

Turn the 2P stitch dial

counterclockwise and remove the 2P stitch

dial screw

.

6.

Turn ON the 2P switch

.

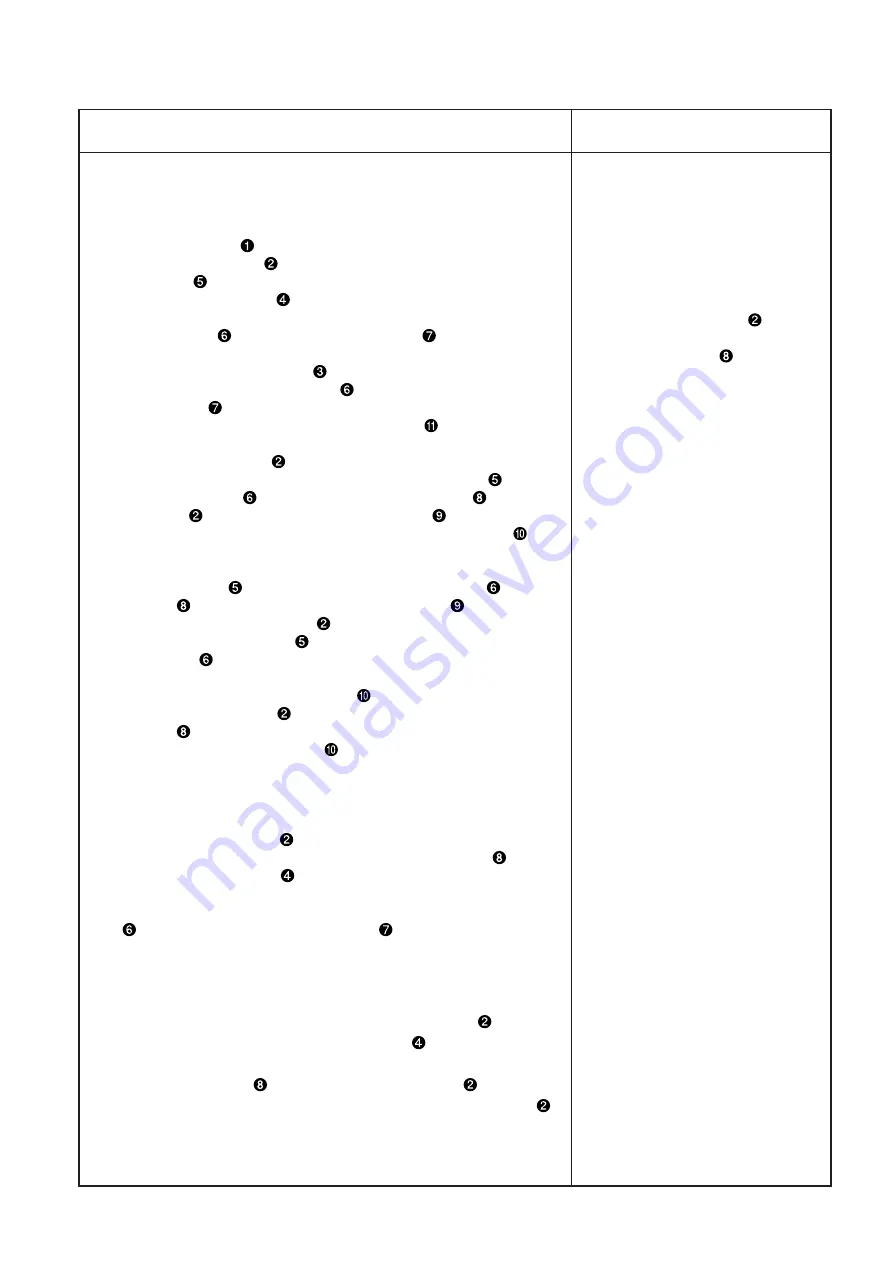

(The air cylinder will work so that the relationship between the 2P

feed regulator

and feed adjusting pin roller

is set as shown in

Fig. A).

7.

Lower the reverse feed lever

so that the cam section (point zero

position) of the 2P feed regulator

is aligned with the feed adjust-

ing pin roller

) (Fig. B).

At that time, the reverse feed connecting arm

is fixed as shown

in Fig. C.

8.

Turn the 2P stitch dial

clockwise slowly until a slight load is felt

(easily sensed by hand), to align the 2P stitch dial screw

with the

2P feed regulator

. At that time, if the dial stopper

on the 2P

stitch dial

is matched with the stitch dial pin

and the dial can

not be turned any more, loosen the 2P stitch dial set screw

and

adjust the dial position. In the case of adjusting the dial position,

adjust it so that around the front or back where the 2P stitch dial

adjusting screw

is aligned with the 2P feed regulator

, the dial

stopper

does not match with the stitch dial pin

.

(Caution) If the 2P stitch dial

is forcibly turned, after the 2P

stitch dial screw

is aligned with the 2P feed regula-

tor

, the point zero position for the 2P adjustment

would be shifted.

9.

Loosen the 2P stitch dial set screw

.

10. Turn the 2P stitch dial

counterclockwise to align with the dial

stopper

position.

11. Fasten 2P stitch dial setscrew

.

[Confirmation]

1.

Perform the above adjusting procedure steps No. 1. through

4.

2.

Turn the 2P stitch dial

counterclockwise and set it at where

it stops (at where it is stopped with the dial stopper

).

3.

Turn on the 2P switch

.

4.

Perform the above adjusting procedure step No. 7. and align

the cam section (point zero position) of the 2P feed regulator

with the feed adjusting pin roller

. Then, when the hand-

wheel is turned and the stitch length set to zero, the 2P stitch

dial point zero setting will have been completed. If it is not (if

the stitch length is not set to zero), perform the adjustment

again.

(Caution) 1. When you turn the 2P feed control dial

, confirm

without fail that the 2P switch

is set at OFF.

2. Graduation 3 or below (where it stops with the dial

stopper

) of the 2P feed control dial

is used for

the calibration of the 2P feed control dial

.

Therefore, it cannot be used for actual sewing work.

3’ In some motor versions an

alarm might sound because

they are not equipped with belt

and alarm output. However, the

alarm will be stop after some

seconds so that, then, continue

the procedure.

10’ For the 2P stitch dial

, the po-

sition where it is stopped with

the dial stopper

, is the point

zero position in the adjustment.

Adjustment Procedure

Results of Improper Adjustment