– 43 –

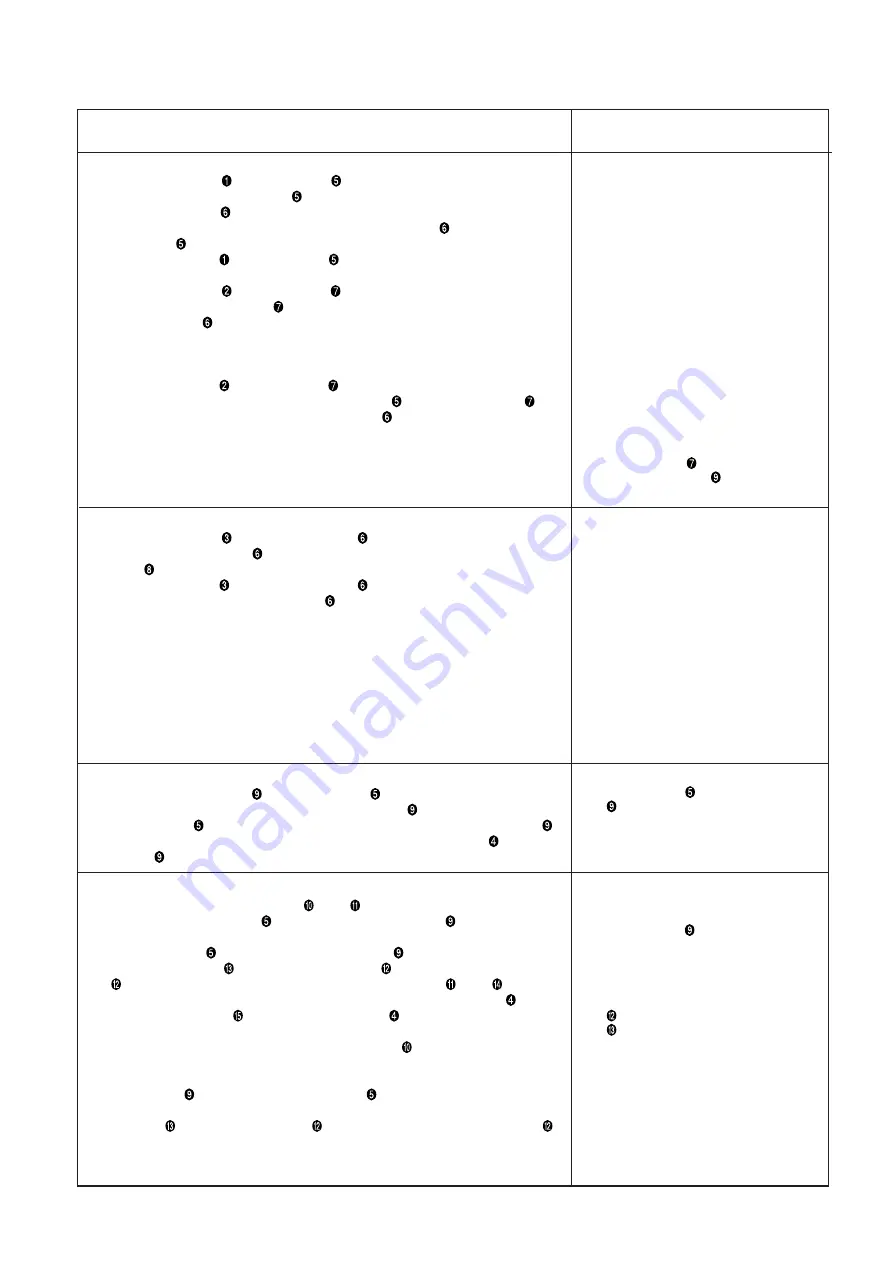

1) Positions of Counter Knife and Clamp Spring

1. Loosen the set screws of the counter knife .

2. Bring the top end of the counter knife so that it comes in contact with the staged section of

the counter knife base .

3. Adjust so that the distance between the end of the counter knife base and the top end of the

counter knife reaches 17.5 mm.

4. Fasten the set screws of the counter knife .

Clamp Spring Position

1. Loosen the set screws of the clamp spring .

2. Bring the end of the clamp spring so that it comes in contact with the staged section of the

counter knife base .

3. While the end of the clamp spring comes in contact with the staged section of the counter knife

base, slide the end of the clamp spring and adjust so that the distance between the clamp

spring and the counter knife reaches 4.1

±

0.1 mm.

4. Fasten the set screws of the clamp spring .

(Caution)

When the positions of the counter knife and the clamp spring are

moved, re-adjust the counter knife base position and knife pressure.

2) Counter Knife Base Position

1. Loosen the set screws of the counter knife base .

2. Move the counter knife base to the position specified in the figure using the counter knife

gauge supplied with the machine.

3. Fasten the set screws

of the counter knife base .

(Caution)

When the counter knife base is moved, re-adjust the knife pressure.

3) Knife Pressure

1. Adjust, when the moving knife and the counter knife come in contact with each other, the

attaching position of the moving knife so that the moving knife starts coming in contact with

the counter knife at the position that is 6 to 7 mm away from the top of the moving knife .

At this time, perform aforementioned adjustment after loosening the set screws of the mov-

ing knife .

4) Moving Knife Driving Arms A, B and C

1. Loosen the moving knife driving arms A and B and adjust so that the distance between

the top end of the counter knife and the top end of the moving knife becomes 0.5 mm. In

the case that a bobbin thread clamp failure occurs when using a thick thread, agree the top end

of the counter knife with the top end of the moving knife .

2. Put the plunger stopper of the thread trimmer solenoid onto the main body of the solenoid

and fasten the clamping screws of the moving knife driving arms B and C .

3. Adjust so that a clearance of 0.2 mm is provided between the thread trimmer cam and the

thread trimmer cam roller when the thread trimmer cam is brought to the highest position

of its stroke (for both the right-hand and left-hand sides).

4. Fasten the clamping screw of the moving knife driving arm A .

[Item to be confirmed]

Turn the hand-wheel by hand to make the sewing machine perform thread trimming and align the top end

of the moving knife with the top end of the counter knife . This is the initial position of the thread

trimming mechanism. At this time, confirm that a clearance of 0.05 to 0.15 mm is provided between the

plunger stopper of the thread trimmer solenoid and the main body of the thread trimmer solenoid .

o If the distance (17.5 mm) from the top end of the

counter knife base to the top end of the counter

knife is larger than the specified value:

• The length of bobbin thread to be clamped will

be shortened, resulting in stitch skipping.

• The bobbin can not be inserted or removed.

o If the distance (17.5 mm) from the top end of the

counter knife base to the top end of the counter

knife is smaller than the specified value:

• Thread trimming failure may be caused.

o If the distance (4 mm) from the counter knife to the

clamp spring is larger than the specified value:

• Bobbin thread clamping failure may be caused.

• Stitch skipping may be caused at the sewing start.

o If the distance (4 mm) from the counter knife to the

clamp spring is smaller than the specified value:

• The clamp spring may clamp the needle thread.

This means that the material may not be taken

out from the sewing position with ease. As a re-

sult, the bobbin thread clamped may be removed

together with the material.

• The clamp spring may interfere with the rear

end of the moving knife , resulting in deforma-

tion of the clamp spring.

o If the distance (1 mm) from the throat plate to the

counter knife is larger than the specified value:

• The knife pressure may increase, resulting in

motor stop.

o If the distance (1 mm) from the throat plate and the

counter knife is smaller than the specified value:

• The knife pressure may decrease, resulting in

thread trimming failure.

o If the distance (33 mm) from the bed slide plate

end surface to the top end of the counter knife is

larger than the specified value:

• The length of bobbin thread to be clamped will

be shortened, resulting in stitch skipping.

o If the distance (33 mm) from the bed slide plate

end surface to the top end of the counter knife is

smaller than the specified value:

• Thread trimming failure may result.

o If the knife pressure is too high:

• The counter knife blade and the moving knife

blade may break.

o If the knife pressure is too low:

• Thread trimming failure may result.

o If the distance from the top end of the counter knife

to the top end of the moving knife is larger than the

specified value:

• The moving knife may overrun after trimming

the thread, resulting in clamping failure.

o If the distance from the top end of the counter knife

to the top end of the moving knife is smaller than

the specified value:

• The main body of the thread trimmer solenoid

may come in contact with the plunger stopper

at the time of thread trimming.

Adjustment Procedure

Results of Improper Adjustment

0

– 0.2