– 63 –

1. Let the sewing machine fall down and manually actuate the [solenoid

valve] in the state that no thread trimming cam roller

is entered in

the cam groove. Assume the condition that the thread trimming air

cylinder is protruded.

(Press the manual switch No. 4 of the [solenoid valve] to assume the

locked state.)

[Refer to 3- (12) –13) Description of the solenoid valve.]

2. Loosen the moving knife return plate setscrew

and remove the

moving knife return plate

.

3. Loosen the moving knife driving arm stopper nut

and then the

moving knife driving arm stopper screw

.

4. Loosen the moving knife driving arm tightening screw

.

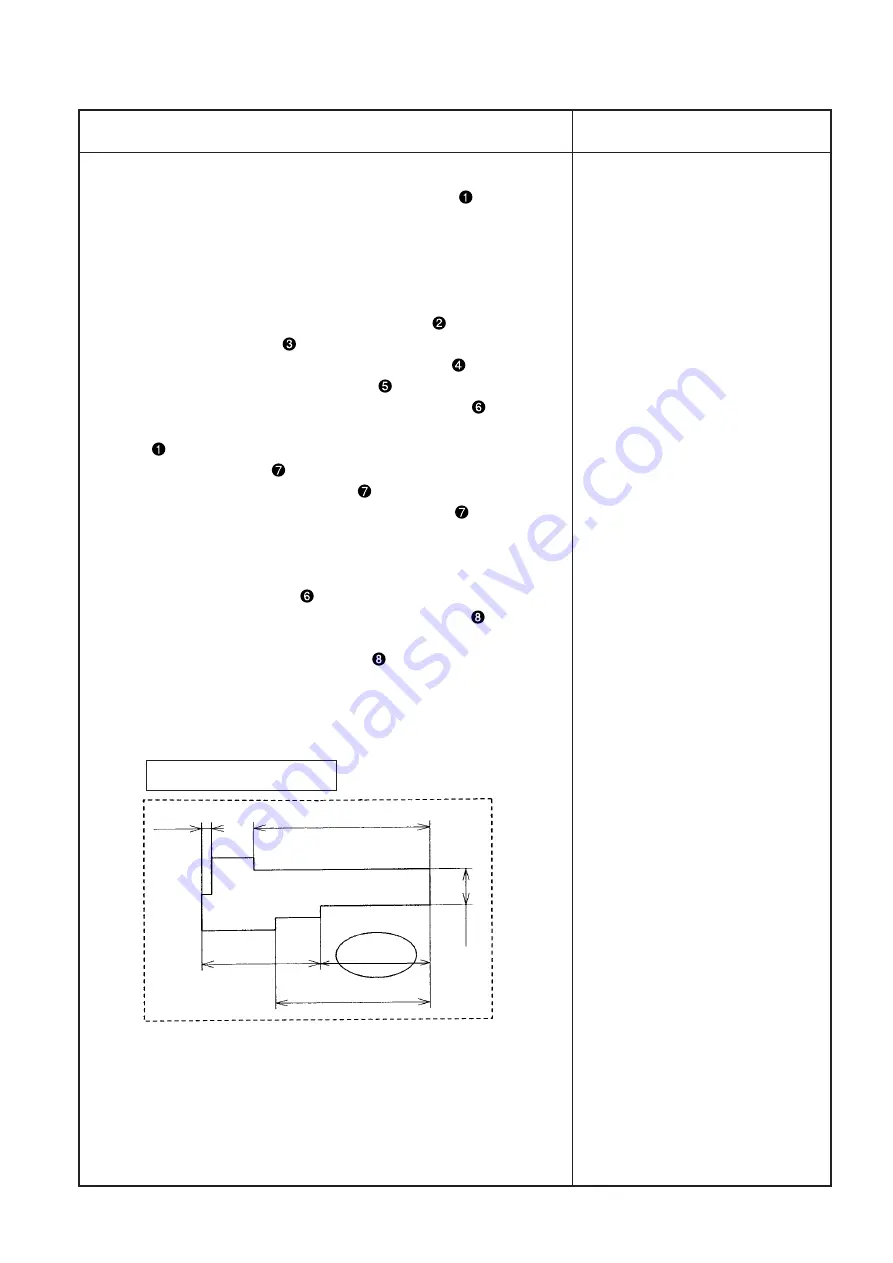

5. Adjust the gap to 0.05 to 0.15mm between the thread trimming cam

roller

and the outer periphery of the thread trimming cam. Then,

adjust the moving knife

to its initial position.

The initial position of the moving knife

is defined when the distance

is 26.8

±

0.2mm between tip of the moving knife

and the bed

groove. (At that time, it is possible to use an accessory adjusting

gauge.)

6. While the state of 5. above is maintained, tighten the moving knife

driving arm tightening screw

. (Tightening torque: 5.88 to 6.86N•m

(60 to 70kgf•cm)) For the moving knife driving arm

in vertical

directions at that time, the gap shall be 1.0

±

0.2mm between bottom

surface of the moving knife driving arm

and the top surface of the

thread trimming cam.

Subsequently, perform “9) Adjustment of gap between the moving

knife driving arm and the moving knife driving arm stopper”.

Adjustment Procedure

Results of Improper Adjustment

Adjusting gauge (accessory)

2.4

43.0

(t = 0.6)

29.0

26.8

37.8

9.0