– 65 –

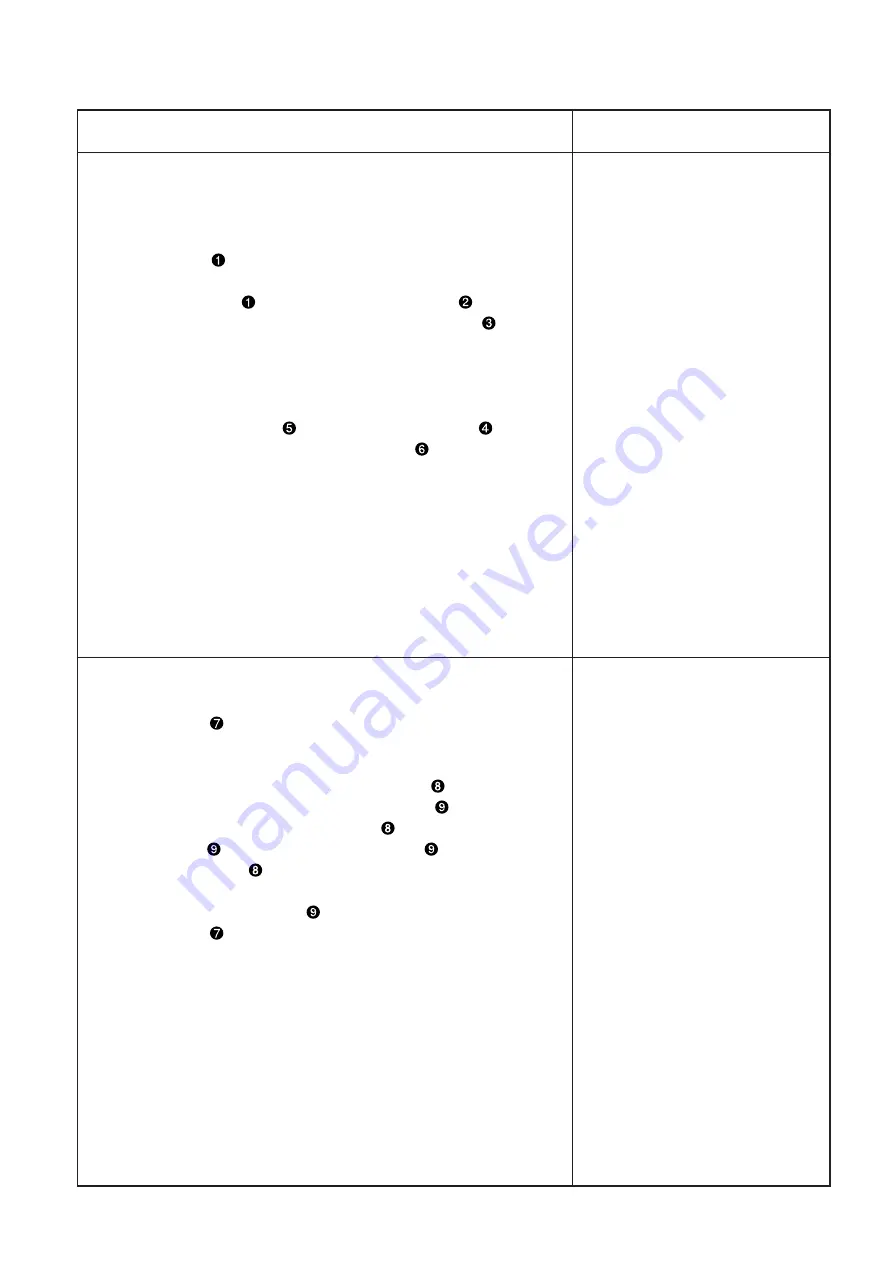

9) Adjustment of gap between the moving knife driving arm and

the moving knife driving arm stopper

1. While the state of 8), Moving knife driving arm and initial position of

the moving knife, is maintained, tighten the moving knife driving arm

stopper screw

.

2. Adjust the gap to 0.05 to 0.1mm between the moving knife driving

arm stopper screw

and the moving knife stopper

.

3. Tighten the moving knife driving arm stopper screw nut

.

10) Mounting position of the moving knife return plate

1. Keeping the gap as per 9) Adjustment of gap between the moving

knife driving arm and the moving knife driving arm stopper, make the

moving knife return plate

contact with the return pin

.

2. Tighten the moving knife return plate setscrew

. Unlock the manual

switch of the [solenoid valve] that has been actuated as per 3. herein.

(Caution) If a machine lock occurs in the middle of thread

trimming, confirm the adequacy of adjusting values

specified in 3.-(12)-8), 3.-(12)-9), and 3.-(12)-10).

If any inadequacy is discovered, readjustments are

required.

11) Adjustment of timing for the thread trimming cam

1. Let the sewing machine fall down and loosen the thread trimming

cam setscrew

.

2. Turn the hand wheel by hand and let the hand wheel graduation [L]

coincide with the upper surface of the hand wheel indicator.

3. Manually make the thread trimming cam roller

come in contact

with the cam groove of the thread trimming cam

.

4. Making the thread trimming cam roller

contact with the thread

trimming cam

, turn the thread trimming cam

so that the thread

trimming cam roller

comes in contact with the starting R part of

the cam groove.

5. Fix the thread trimming cam

with the use of the thread trimming

cam setscrew

.

Adjustment Procedure

Results of Improper Adjustment