– 93 –

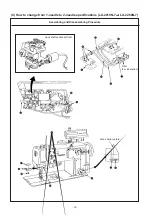

11. Loosen the clamping screws

and

of the feed adjusting arm

and the feed adjusting pin support arm

(For LU-2212N-7 and

LU-2220N-7).

12. Loosen the clamping screw

of the thrust collar

.

13. Loosen the clamping screw

of the reverse feed connecting arm

.

14. Set the stitch dial

to the maximum value on the scale. Then,

remove the face aperture plate on the front face of the sewing ma-

chine.

15. Loosen the clamping screw

(two locations) of the feed adjusting

pin

. (For LU-2212N-7 and LU-2220N-7)

16. Remove the tension spring

of the reverse feed lever

. Draw out

the reverse feed lever shaft

to a position where the timing belt

can be removed. Then, remove the spring rack hook

, the feed

adjusting tension spring

, the feed adjusting arm

and the feed

adjusting pin support arm

(For LU-2212N-7 and LU-2220N-7).

17. Replace the timing belt with a new one and put it on the upper

sprocket.

18. Insert the reverse feed lever shaft

inside the periphery of the

timing belt. Attach the feed adjusting pin support arm

(For LU-

2212N-7 and LU-2220N-7), spring rack hook

and feed adjusting

arm

onto the reverse feed lever shaft

.

19. Insert the reverse feed lever shaft

in the shaft hole in the ma-

chine arm. Fasten the set screw

of the thrust collar

.

20. Fasten the set screw

of the feed adjusting pin

. At that time,

fasten the screw so that the pin roller

is in a position where it

rotates smoothly. (For LU-2212N-7 and LU-2220N-7)

21. Fasten the set screw

of the feed adjusting arm

. At that time,

fluctuate the feed adjusting arm

to the right and left until the feed

adjusting arm

is placed almost at the center of the play, then

fasten the clamping screw.

(Caution)

Fasten the clamping screw with a tightening torque of

3.92 to 4.9 N•m (40 to 50 kgf•cm).

22. Fasten the clamping screw

of the feed adjusting pin support arm

(For LU-2212N-7 and LU-2220N-7).

23. Put the feed adjusting tension spring

onto the spring rack hook

and the feed adjusting eccentric pin.

24. Fasten the clamping screw

of the reverse feed connecting arm

and attach the face aperture plate on the front face of the sewing

machine.

25. Attach the tension spring

of the reverse feed lever

in place.

Assembling and Disassembling Procedure

Results of Improper Adjustment

11’ Insert the screwdriver from the

aperture plate side.

12’ Insert the screwdriver from the

aperture plate side and from the

under surface of the bed.

14’ F o r L U - 2 2 1 2 N - 7 a n d L U -

2220N-7:

• Set the stitch dial to the maximum

value on the scale. After that, re-

move the 2P stitch dial

. Loosen

the set screw

of the aperture

plate on the front face of the sew-

ing machine and remove the face

aperture plate B

on the front

face of the machine.

19’ Fasten the set screw

of the

thrust collar

while eliminating

a thrust play at the reverse feed

lever shaft

.

21’ If the feed adjusting arm

is

not correctly positioned, the feed

connecting rod may fail to oper-

ate normally, the feed adjusting

arm

may interfere with the in-

ner wall of the arm, and the feed

adjusting arm

may be pushed

against the side face of the feed

crank stud. In this case, the re-

verse feed lever

may not be

lifted/lowered smoothly.

23’ Set the stitch dial

to the maxi-

mum value on the scale. Adjust

so that a clearance of 0.5 to 1.5

mm is provided between the re-

verse feed lever

and the stop-

per when the reverse feed lever

is slightly pushed down, and

then fasten the clamping screw

.

(Refer to [3.-(8) Position of the

Reverse Feed Connecting Arm]

for further details.

24’ F o r L U - 2 2 1 2 N - 7 a n d L U -

2220N-7:

• Fasten the clamping screw

of

the reverse feed connecting arm

and attach the face aperture

plate B

on the front face of the

machine. After that, attach the 2P

stitch dial

.