–

16

–

Standard Adjustment

Results of lmproper Adjustment

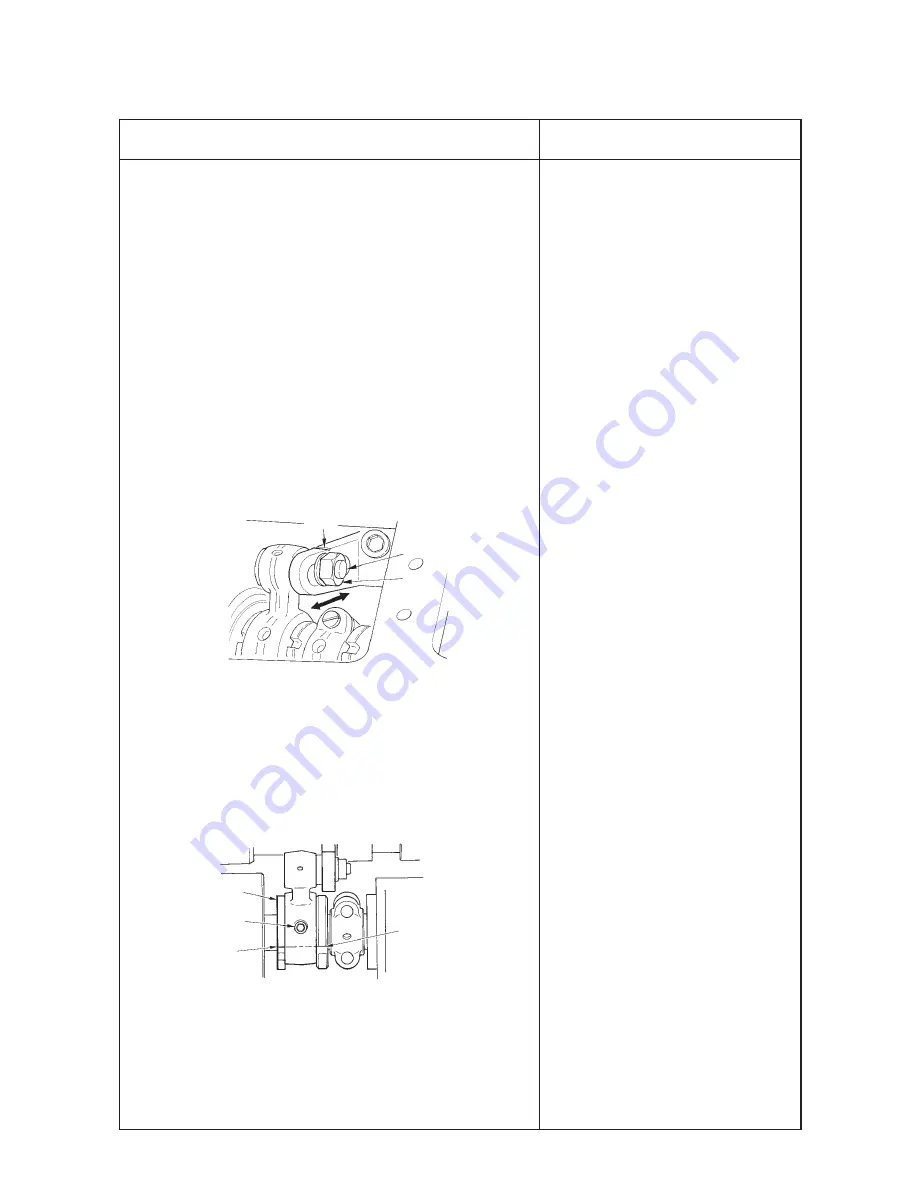

1. Adjusting the height of the spreader

2. Adjusting the longitudinal position of the spreader

Loosen setscrew

3

and adjust the height and longitudinal position

of the spreader

1

.

3. Protruding amount of the spreader

Loosen setscrew

4

in the spreader folder and adjust the protruding

amount. Adjust aiming the adjustment figure of 5 mm.

4. Adjusting the spreader stroke

Standard position is the position where the engraved marker line of

spreader drive lever

5

aligns with the center of the shaft of

connecting pin

6

. When desired to increase the stroke, loosen

lock nut

7

and move in the right direction. When desired to decrease

the stroke, loosen lock nut

7

and move in the left direction. Adjust

aiming the adjustment figure of 17 mm.

5. Adjusting the timing between the needle bar and the spreader

When changing the timing, loosen two setscrews

9

in spreader

eccentric cam

8

to adjust. Standard position is the position where

notch

!0

in the main shaft aligns with notch

!1

in spreader eccentric

cam. When changing, turn the upper pulley and change with

spreader eccentric cam

8

fixed.

™

Height of the spreader is improper,

stitch skipping of spreader occurs.

™

Adjust the height in accordance with

the needle gauge.

™

Even when the protruding amount is

excessive or insufficient, stitch

skipping of spreader will be caused.

™

When the protruding amount is

insufficient, it will be the cause for left

needle not to scoop covering thread

at overlapped section.

™

When the stroke is increased, disorder

of covering thread stitching will be

caused.

™

When the stroke is decreased, stitch

skipping of spreader will be caused.

™

When the timing is excessively

advanced, needle does not take

covering thread when it comes down

and stitch skipping will be caused.

™

When the timing is excessively

retarded, resistance increases when

covering thread slips out from the

spreader and a load is applied to the

right needle. As a result, needle

breakage or stitch skipping will be

caused.

(Caution) When changing, temporarily

tighten No. 2 screw in the

rotation direction of setscrews

9

and turn the upper pulley

to change.

8

9

!0

!1

7

6

5