– 2 –

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

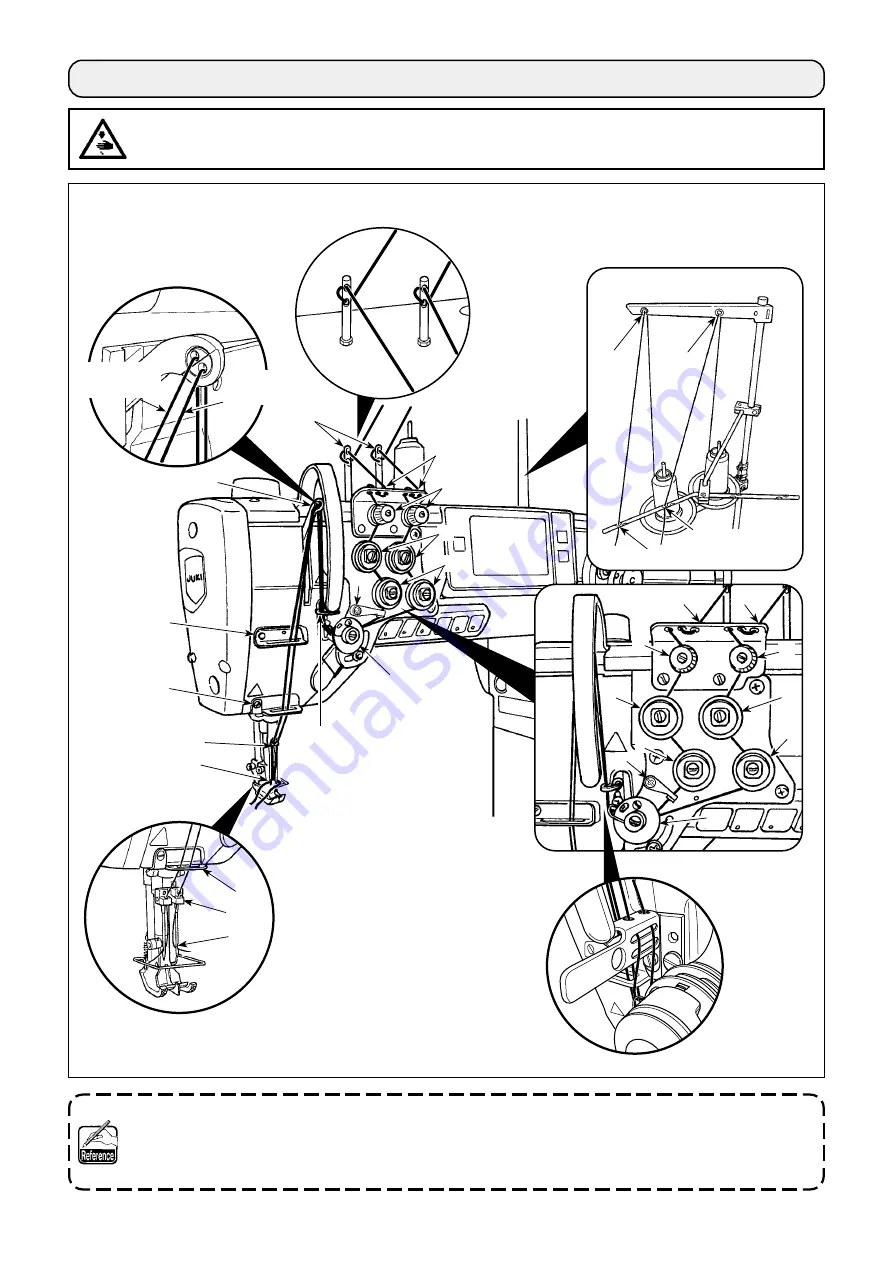

Thread the machine head following the order as

illustrated in the figure.

If you want to perform thread trimming at a position where no material exists, it is necessary to

change thread guide

with the suitable thread guide. The thread guide to be used instead of the

current one is supplied with the unit as an accessory.

Part number of replacement thread guide: 40034675

❻

❸

❼

❹

❶

❾

❺

❷

❶

❷

❼

❹

❻

❹

❺

❺

❼

❻

❾

❽

❽

Left-hand

needle thread

Right-hand

needle thread

2. Threading the machine head