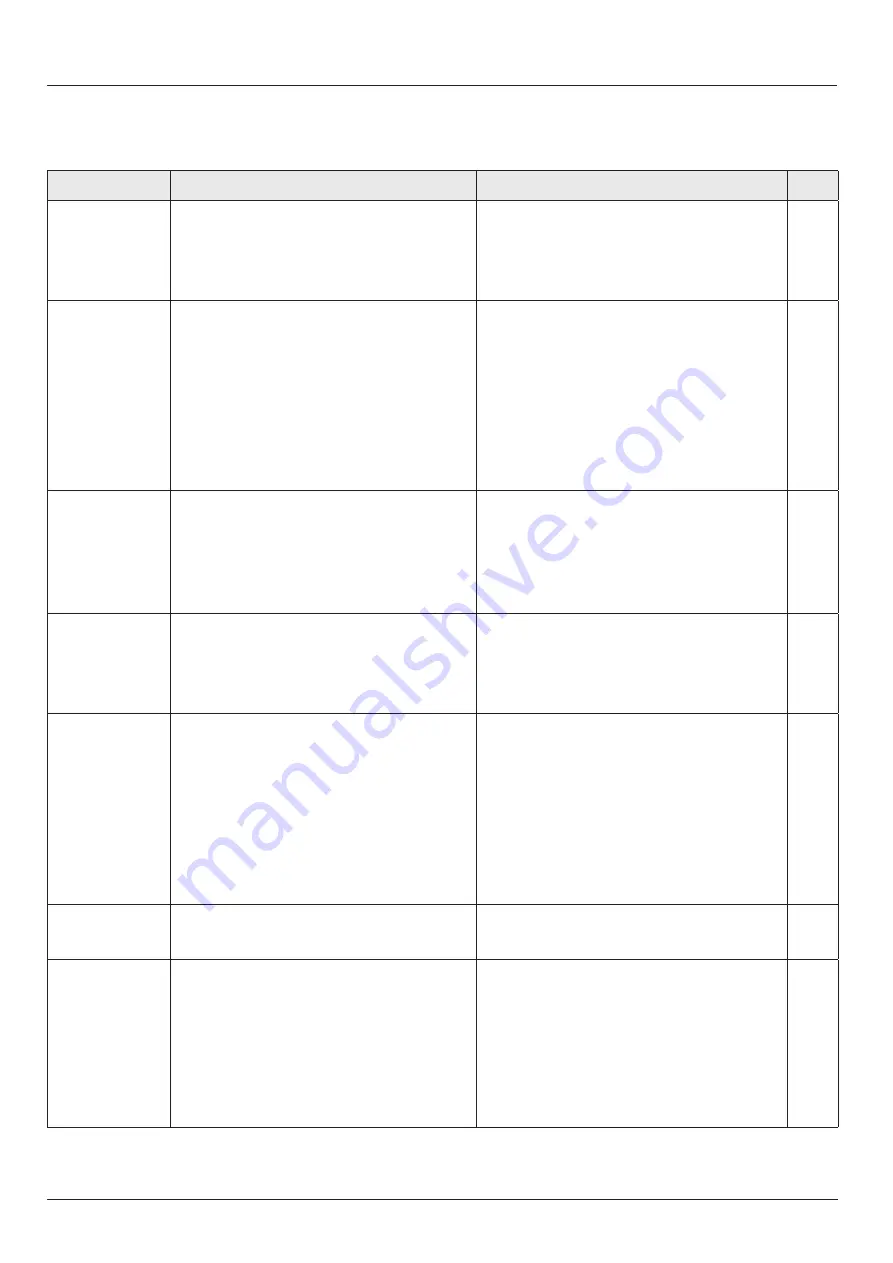

Troubles and Corrective Measures

If sewing difficulties occur, make sure the instructions are correctly followed. If a problem still exists, the re

-

minders below help to solve it.

Troubles

Case

Corrective measures

Page

Stitches are

skipped.

1. The needle is bent or the needle point

is blunted.

2. The needle has not been attached to

the needle bar properly.

• Replace the needle.

• Attach the needle properly to the needle

bar.

22

22

Needle thread

breaks.

1. The machine head has been threaded

incorrectly.

2. The needle thread tension is too high

or low.

3. The needle is bent or the needle point

is blunted.

4. The needle is not suited to the thread

used.

• Correct the threading.

• Properly adjust the thread tension.

• Replace the needle.

• Replace the needle by the one suited to

the thread used.

15-17

20

22

21

The bobbin

thread breaks.

1. The bobbin thread tension is too high.

2. The rubbing of the bobbin case spring

has produced a slot.

3. Scratches on the needle hole in the

throat plate.

• Decrease the tension.

• Replace the bobbin case.

• Replace the throat plate.

20

-

-

The needle

breaks.

1. The needle is bent or has been in-

stalled improperly.

2. The needle hits the throat plate or the

presser foot.

• Replace or correctly attach the needle.

• Correctly position the needle, throat

plate, or presser foot.

22

-

Stitches are

puckered.

1. The presser foot applies too much

pressure to the material.

2. The tension of the needle thread is not

balanced with that of the bobbin thread.

3. When the combination of the needle

and the thread is improper.

4. The needle is too thick for the material.

• Decrease the pressure of the presser

foot.

• Balance the tension.

• Properly correct the combination of nee-

dle and the thread.

• Replace the needle by the one suited to

the material.

10

20

21

21

Stitch perfor

-

mance is bad.

1. The tension of the needle thread is not

balanced with that of the bobbin thread.

• Balance the tensions.

20

The rotation

noise is too

heavy or too

high.

1. Dust accumulates in the feed dog.

2. The oil in the machine has run out due

to a long period of usage.

3. The oil other than the exclusive sewing

machine oil is used.

4. Thread wastes accumulate in the hook.

• Carry out maintenance of your sewing

machine.

• Carry out maintenance of your sewing

machine.

• Apply the proper sewing machine oil.

• Clean up the sewing machine.

30

30

30

30

32