–

8

–

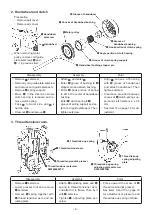

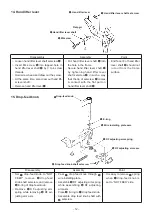

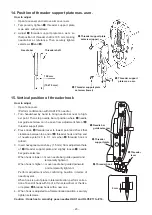

7. Reverse feed stitch lever

Preparation

○

Remove belt cover.

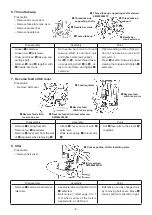

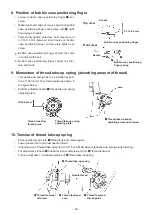

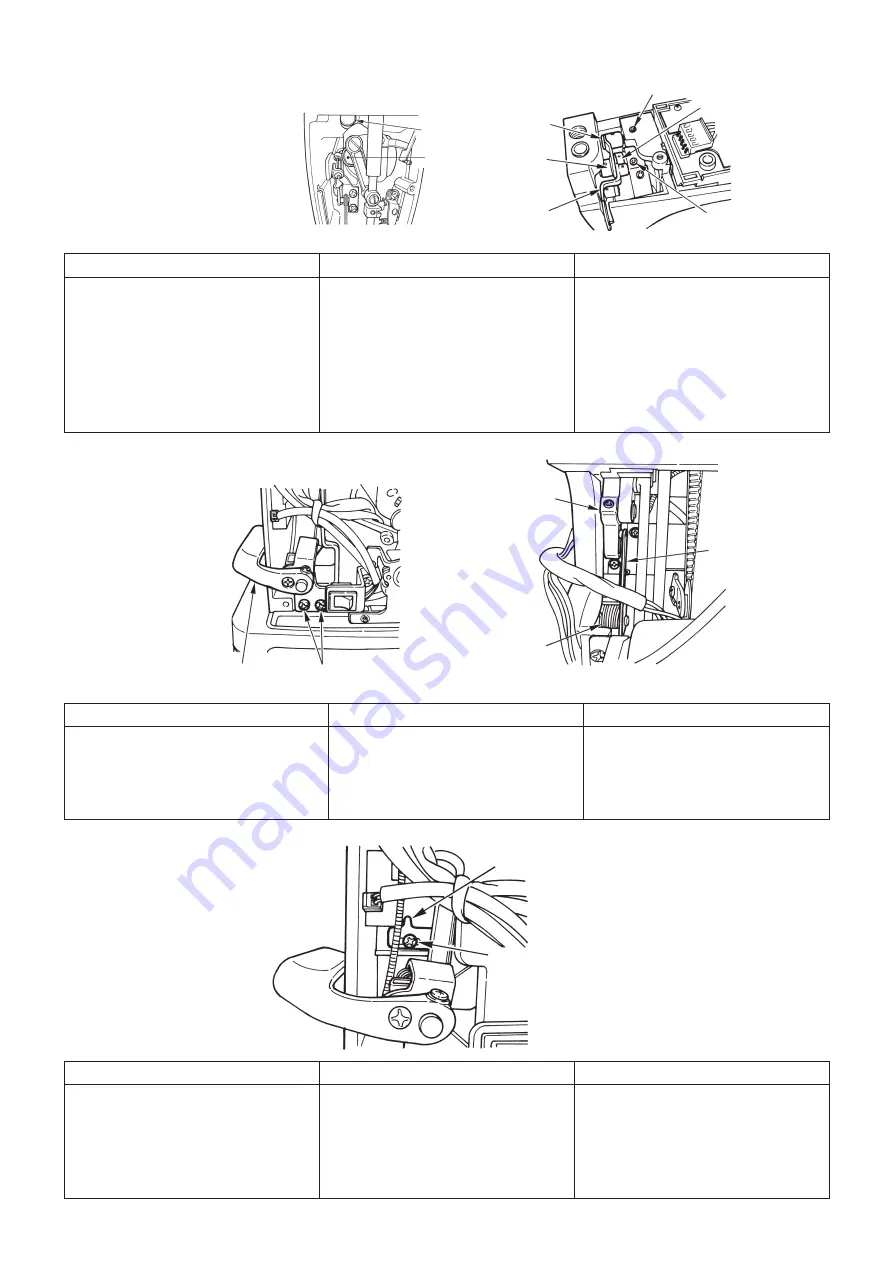

8. Idler

Preparation

○

Remove belt cover.

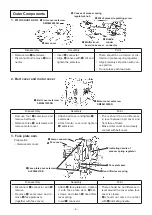

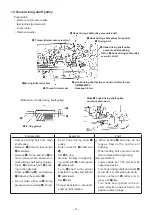

6. Thread take-up

Preparation

○

Remove arm cover asm.

○

Remove face plate mas. asm.

○

Remove presser bar.

○

Remove needle bar.

❷

Convex portion of idler installing plate

❶

Idler setscrew

SM5040855SN

❺

Feed regulator

❶

Reverse feed

stitch lever spring

❹

Reverse feed

stitch lever arm

❷

Needle bar

crank setscrew

❺

Thread take-up

❶

Thread take-up supporting shaft setscrew

SM8050602TP

❸

Thread take-up

supporting shaft

❹

Needle bar crank

❻

Thread take-up

support

❸

Reverse feed stitch

lever mas. asm.

❷

Reverse feed stitch lever setscrew

SM5040855SN

Disassembly

Assembly

Point

○

Loosen

❶

setscrew.

○

Loosen two

❷

setscrews.

○

Draw out thread

❸

take-up sup-

porting shaft.

○

Remove

❺

and

❻

together with

❹

needle bar crank.

○

Set needle bar crank to thread

take-up, attach it onto main unit

and tighten setscrews (2 pcs.).

○

Set

❻

to

❺

, enter thread take-

up supporting shaft

❸

to

❻

, at-

tach it onto frame and tighten

❶

setscrew.

○

Tighten setting portion (flat por-

tion) of needle bar crank with

screw No. 1.

○

Press

❸

shaft to frame side while

viewing the torque and tighten

❶

setscrew.

Disassembly

Assembly

Point

○

Remove

❶

spring from arm.

○

Remove two

❷

setscrews.

○

Remove

❹

lever arm from the slot

of

❺

regulator when removing

❸

.

○

Attach

❸

lever and set with

❷

setscrews.

○

Hook lever spring

❶

to lever arm

❹

.

○

Set

❹

lever arm to the slot of

❺

regulator.

Disassembly

Assembly

Point

○

Remove

❶

setscrew and remove

idler asm.

○

Assemble idler and tighten it with

❶

setscrew.

○

Belt tension : Belt sags 6 to 7

mm when center of the belt is

applied with a 1.96N load.

○

Belt tension can be changed only

by removing belt cover. Move

❷

convex portion to the left or right.

Summary of Contents for TL Series

Page 31: ......