–

15

–

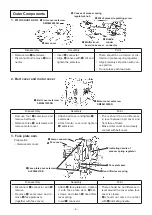

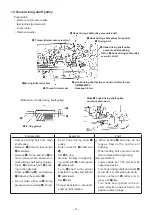

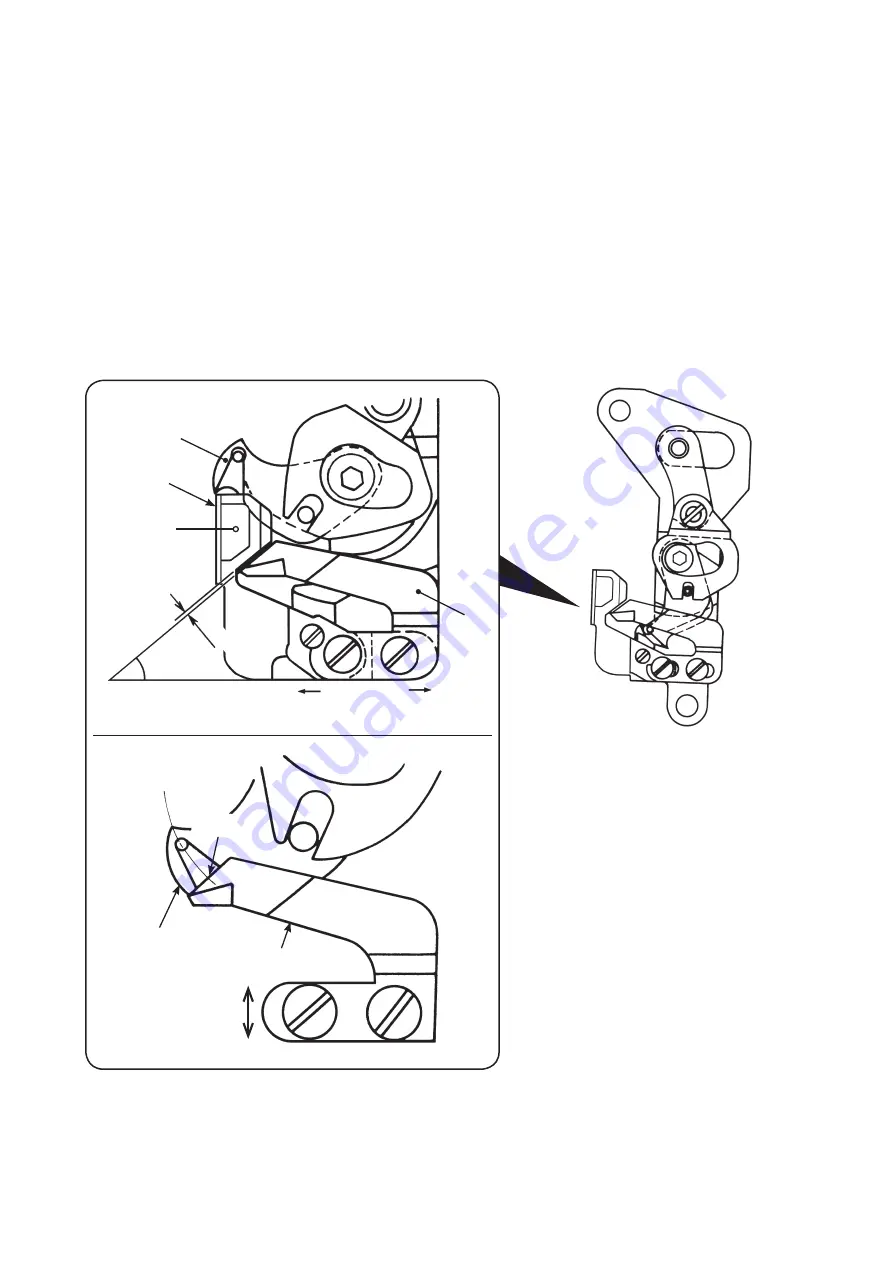

[Adjusting the counter knife]

1)

Properly installing the knife thread guide

Install the knife thread guide

❶

so that the needle enters exactly the center of its opening.

2) Properly installing the counter knife

1. The standard distance from the blade point of the counter knife

❷

to the knife thread guide

❶

, which is posi-

tioned so that the needle enters the center of its opening, is 0.5 mm.

2. The blade point of the counter knife

❷

is about 4 mm away from the center of the needle.

3. The sharpness of the counter knife

❷

depends upon the installing angle of the blade point of the counter

knife

❷

. The proper overlap of the counter knife

❷

blade with that of the moving knife

❸

will provide the best

sharpness.

4. Whenever the counter knife

❷

has been readjusted or replaced, be sure to check the sharpness of the count-

er knife

❷

, and adjust the installing angle of the counter knife

❷

.

Short

Center of

needle

❷

❸

❶

Long

Length of thread remaining on needle

0.5 mm

Center

❷

❸

Summary of Contents for TL Series

Page 31: ......