–

25

–

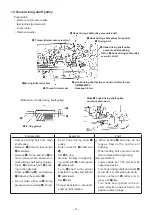

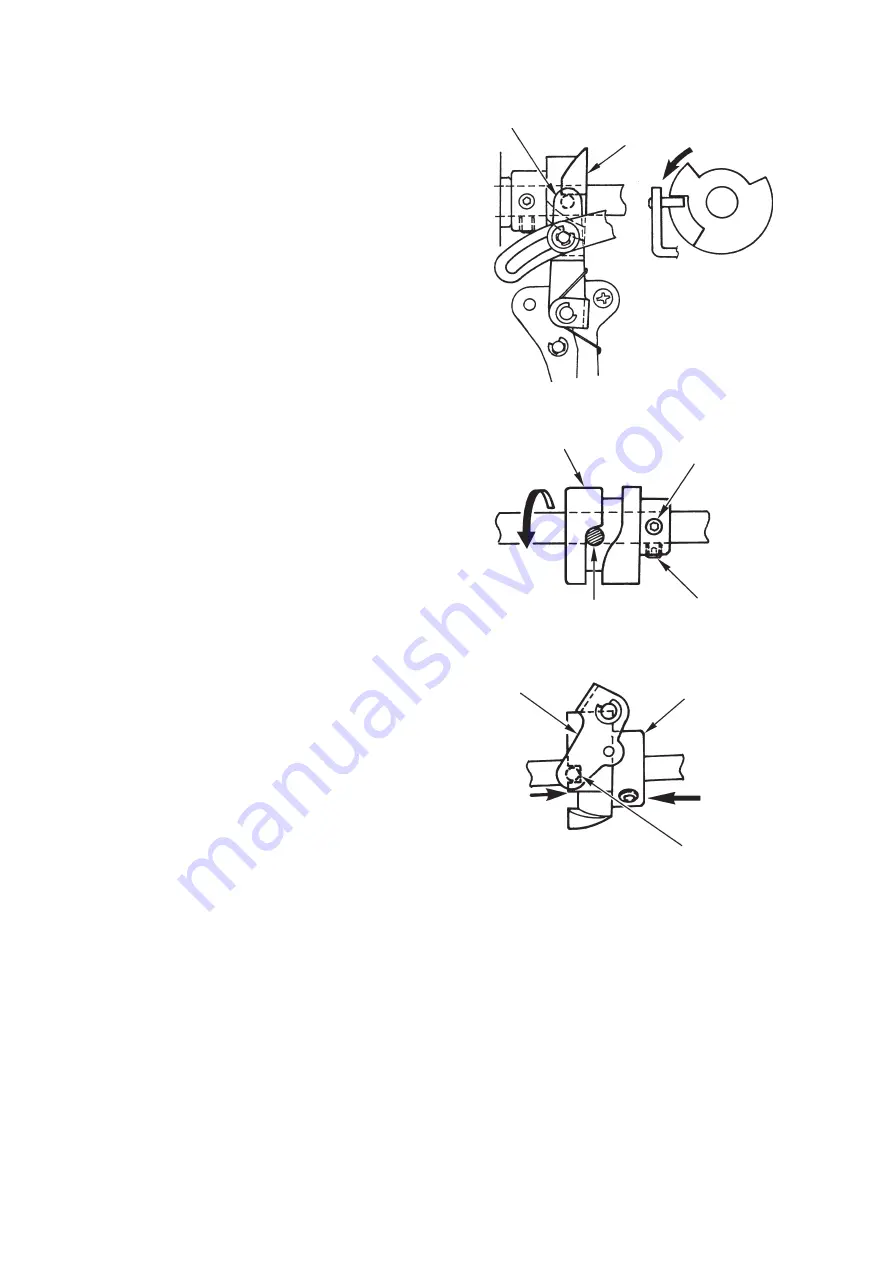

3. Thread trimmer cam timing (Needle-to-cam position)

○

Loosen setscrews in

❶

thread trimmer auxiliary

cam,

❷

thread trimmer cam and

❸

roller holding

cam.

○ Lower needle bar by 37˚ (1.95 mm) from its upper

dead point.

○

In this state, fix hook driving shaft and perform

positioning of cams of

❶

,

❷

and

❸

.

3-1 Positioning of [thread trimmer auxiliary cam]

○

Make shaft at top end of

❹

thread trimmer auxil-

iary link of solenoid asm. come in contact with

❶

thread trimmer auxiliary cam and tighten it with

setscrew.

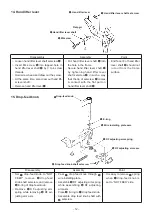

3-2 Positioning of [thread trimmer cam]

○

Face front

❺

setscrew No. 1 in thread trimmer

cam.

○

Enter

❻

thread trimmer cam contactor shaft to

groove in

❷

thread trimmer cam.

○

Slightly pressing thread trimmer cam to hand-

wheel side, turn it in reverse direction.

○

Tighten thread trimmer cam with setscrews at

place where idling term of cam groove (place

where rotation is hindered) is finished.

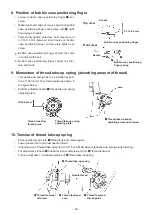

3-3 Positioning of [roller holding cam]

○

Turn pin of link support plate and make it come in

contact with concave portion of

❸

roller holding

cam.

○

For lateral position, make

❸

roller holding cam

come in contact with

❶

thread trimmer auxiliary

cam and tighten it with setscrew.

3-4 Securely tighten setscrews in respective cams

❷

Thread trimmer cam

❹

Thread trimmer auxiliary link

❶

Thread trimmer auxiliary cam

❺

Setscrew No. 1

Setscrew No. 2

❸

Roller holding cam

Link support plate

Convex portion

❻

Thread trimmer cam

contactor shaft

Summary of Contents for TL Series

Page 31: ......