–

27

–

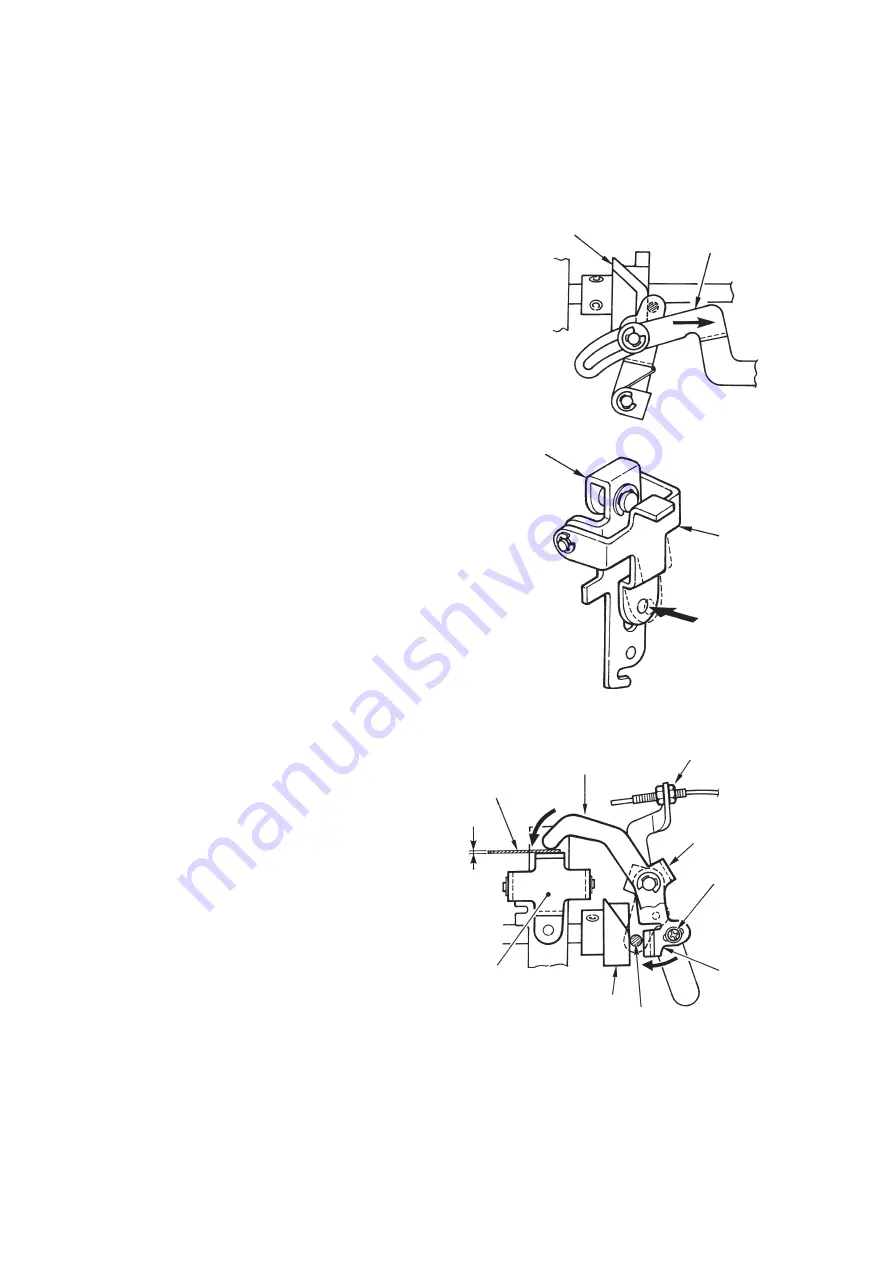

3-7 Confirmation of working and positioning of link arm fixing plate (Timing of thread

trimmer auxiliary cam, thread trimmer cam and thread trimmer holding cam)

○

Set thread trimmer solenoid asm. to ON state, and make pin at top end of thread trimmer auxiliary link per-

fectly align with

❶

thread trimmer auxiliary cam.

○ Rotate sewing machine by hand up to flat section

of

❶

thread trimmer auxiliary cam (place where

it moves to extreme right-hand side). At this time,

❷

thread trimmer solenoid link A moves to right-

hand side.

○

Looper link arm works and presses moving knife

roller arm since

❷

thread trimmer solenoid link A

moves.

Turn handwheel and confirm time when link sup

-

port plate pin rides on flat portion of roller holding

cam.

○

Confirm that thread trimmer contactor shaft

caulked in

❸

moving knife roller arm enters

groove in thread trimmer cam.

○

Press thread trimmer contactor shaft

ⓐ

section

of

❷

moving knife roller arm to make it come in

contact with moving knife arm asm.

○

Insert a clearance gauge of 0.5 mm to contact

part of

❹

moving knife roller arm asm. and

❺

looper link arm asm. and press

❺

looper link arm

asm. to

❹

moving knife roller arm asm.

○

In aforementioned state, make

❻

link arm fixing

plate come in contact with

❼

link arm support

plate pin, and fix it with setscrew.

○

Adjustment of position of

❽

nut of wire setscrew

(Refer to item 5 of adjustment of thread tension

disk open/close, p.27.)

○

After adjustment of position of looper, tighten

looper link setscrew. (Refer to item 4, p.27.)

Roller holding cam

Setscrew

❽

Nut

❻

Link arm

fixing plate

❹

Moving knife

roller arm

❺

Looper link arm

0.5 spacer

❼

Link arm support

plate

Link arm support

plate pin

❶

Thread trimmer

auxiliary cam

❸

Moving knife

roller arm

Moving knife arm

ⓐ

❷

Thread trimmer

solenoid link A

Summary of Contents for TL Series

Page 31: ......