6

Pressure vessel

Pressure tested at: 425 liter:

4050 liter:

Directions for use

Application

Receiver for compressed air.

Receiver specifications See name plate.

Installation

Tubes, etc. must be made of

suitable materials.

Placement

Observe the working temperature

of the receiver.

Ensure that sufficient room for

inspection/maintenance is

available in a horizontal position.

The receiver must be kept in a

horizontal position.

Corrosion protection

The surface treatment must be

maintained as required.

Internal inspection at least every

5 years.

Drain moisture at least once a week.

Alternation/repair

No welding must be made on

pressurized parts.

Safety valve

Ensures that PS will not be exceeded.

Never adjust to a higher pressure

than PS.

The capacity of the valve must be

calculated in accordance

with the volume of air supplied by

the compressor.

(PS = Maximum working pressure

of the receiver)

Declaration of Conformity

NOTE: The declaration of conformity is only valid for units

operating at 20 V/50 Hz, x400 V/50 Hz, 12 V DC or 24 V DC.

The manufacturer, JUNAIR International A/S, declares that the

products mentioned in this manual are in conformity with:

• 87/404/EEC 90/488/EEC 9/68/EEC Council Directive

relating to Simple Pressure Vessels

• 89/92/EEC 91/68/EEC 9/44/EEC 9/68/EEC

Council Directive of Safety of Machinery

• 89/6/EEC Council Directive of Electric Magnetic

Compatibility

• 7/2/EEC Lowvoltage Directive

Flemming Petersen

Quality Manager

24 bar

18.3 bar

c) Failure in nonreturn valve which is creating a flow

restriction.

d) Check the piston gaskets. Replace, if necessary.

e) Desiccant has been contaminated and/or filter elements

have been clogged (this only applies to model „D“).

Replace. See "Adsorption Dryer Manual".

4. Loud noise from compressor:

a) Dirt or failure in nonreturn valve. Clean or replace.

b) Defective fan (this only applies to model „P“).

5. Compressor gets very hot:

a) Leaks. See point b.

b) Intake filter clogged. See point a.

c) Too high ambient temperature. Do not enclose unit in a

cupboard unless adequately ventilated. The compressor

should be placed in coolest possible place.

d) The cooling fan at the top of the cabinet does not run

(this only applies to model „P“). Check pipes and fuses.

e) Overloaded. Ensure compressor is correct model for

work load.

6. Compressor starts when no air is being tapped:

a) Leaks. See point b.

7. Compressor starts and stops more frequently than

usually:

a) Large amount of condensate in air receiver (on units

without dryer). On units with dryer condensate may be

found if dryer is defective (this only applies to model

„D“).

b) Leaks. See point b.

8. Compressor does not switch on against pressure or

does not switch off at max. pressure:

a) Defective pressure switch. Replace.

Operating manual

GB

Summary of Contents for 1000 motor

Page 2: ......

Page 11: ...11 10 4 A B 6 B A 6 8 90 120 psi 50 15 8 120 psi 15 14 2 30 psi 32 89 F BD PD 2000 RU...

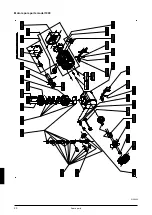

Page 20: ...20 Motor spare parts model 1000 0100400 Spare parts...

Page 21: ...21 Motor spare parts model 2000 0200300 Spare parts...

Page 22: ...22 0200600 Spare parts model 2000 40B Spare parts...

Page 23: ...23 Spare parts model 2000 40BD2 0200610 Spare parts...

Page 24: ...24 0200620 Spare parts model 2000 40P Spare parts...

Page 25: ...25 0200630 Spare parts model 2000 40PD2 Spare parts...

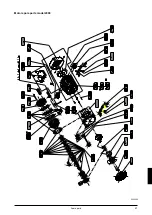

Page 26: ...26 Spare parts model 4000 40B 0400200 Spare parts...

Page 27: ...27 Spare parts model 4000 40BD3 0400210 Spare parts...