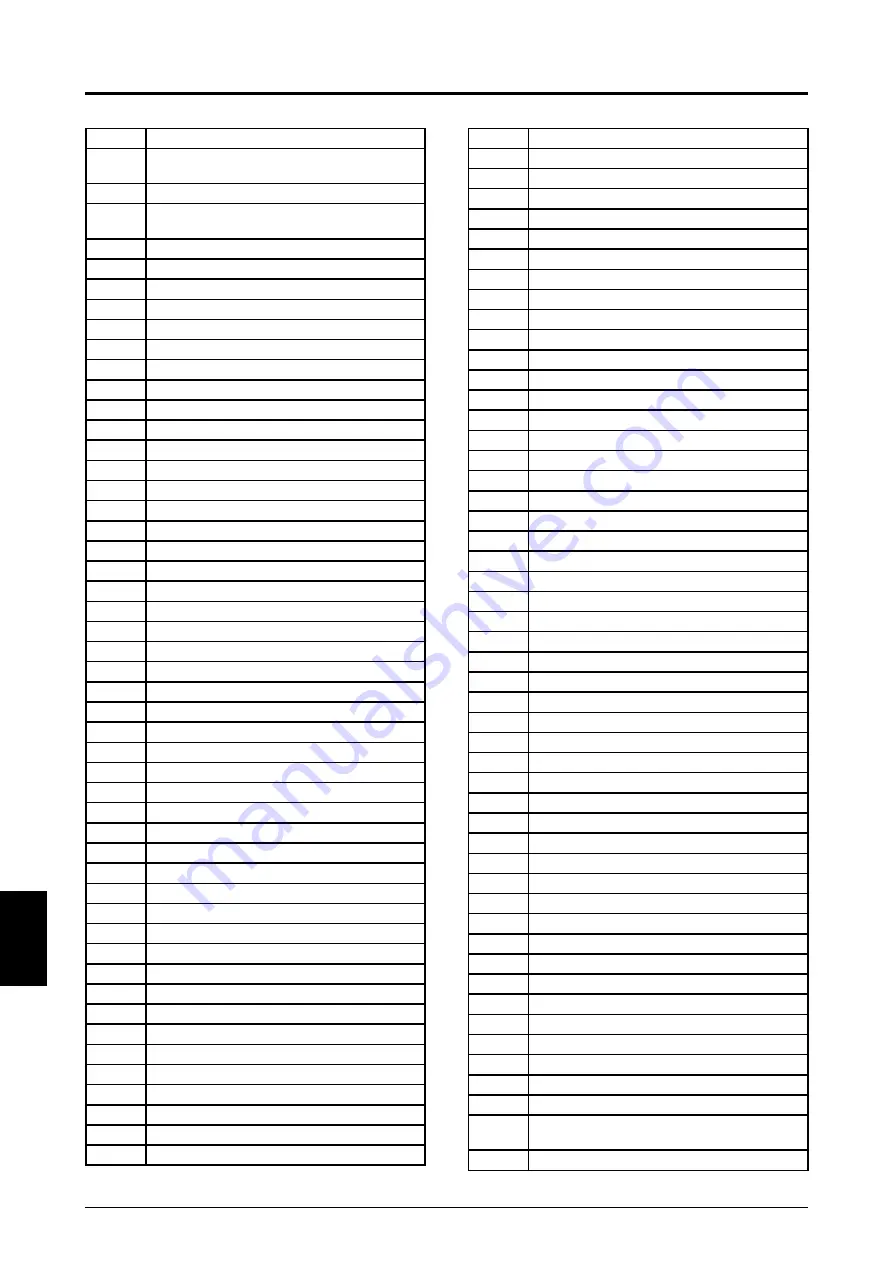

0

Spare parts

010099

Receiver 4l without inspection plug CE, silver

050099

Receiver 4l with inspection plug CE, silver, internally

coated

210095

Receiver 15l with inspection plug ASME, silver

210099

Receiver 15l with inspection plug, CE, silver, fluid in

nozzle

410092

Receiver 25l with inspection plug, ASME, silver

410099

Receiver 25l with inspection plug, CE, silver

512097

Receiver 40l with inspection plug, CE/ASME, silver

695298

Receiver 150l with inspection plug, CE, silver

4070500

Activated carbon filter DH AC000G

4071000

Filter 5um w/manual drain

4071020

Regulator R07280RNMG, 10 bar

407100

Filter regulator 5um w/manual drain

4071055

Filter 0.01um w/manual drain

4071080

Lubricator L07220MPMG

4110000

Rapid coupler 1/4” external thread CEJN

4120000

Nipple 1/4”

410000

Hose tail nipple 1/4” f/rapid coupler

4210000

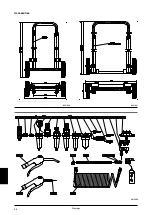

Trolley f/610/15/25

4211000

Trolley f/64/1.5

410000

Blow gun black

411000

Blow gun black f/inflators

480000

Ball inflator

481000

Bicycle inflator

482000

Car tyre inflator

48000

Hose clamp 812 mm

4410000

PVC air hose 1/4”

440000

Recoil air hose 1/4” 7.5m black

4520000

Overload protector f/6 motor 20V

4521000

Overload protector f/6 motor 120V

4522001

Overload protector f/ motor 20V (new)

4522201

Overload protector f/ motor 120V (new)

4522500

Overload spring f/6 motor

452000

Starting relay 20V f/6 motor

4524000

Starting relay 120V f/6 motor

4526001

Starting relay f/ motor 20V (new)

4526201

Starting relay f/ motor 120V (new)

4526500

Terminal box compl. f/ and 6 motors

4526600

Cover f/terminal box f/ and 6 motors

4527000

Fastening spring f/ and 6 motors

4528000

Bolt f/top bearing f/6 motor

4529000

Top bearing f/6 motor

4545000

Cover f/6 motor

4546000

Gasket f/cover f/6 motor

4547000

Pressure pipe f/6 motor (incl. gasket)

4548000

Gasket f/pressure pipe f/6 motor

4549000

Bolt f/pressure pipe f/6 motor

4550000

Copper washer f/6 motor

4551000

Suspension spring f/6 motor

4555000

Cylinder head f/6 motor

4556000

Bolt f/cylinder head f/6 motor

4560100

Casing bottom f/ motor 20V silver (new)

4561000

Casing bottom f/6 motor silver

4571000

Rib cover f/6 motor, silver

457400

Rib cover f/ and 4 motors silver

4610201

Cylinder head f/ motor (new)

4610501

Spring w/bushing f/ motor (new)

4610601

Top bearing f/ motor (new)

461101

Cover f/terminal board f/ motor (new)

461150

Bracket f/terminal board f/ motor (new)

461160

Bracket f/klixon f/ motor (new)

4646000

Gasket f/cover (= 4548000)

4649500

Bolt f/safety valve f/ motor

4656000

Bolt f/cylinder head f/ motor

4750000

Control lamp 20V

4750200

Control lamp 120V

500000

Pressure switch MDR 2/11 compl.

50000

Pressure switch MDR 21/11 w/unloader

505000

Pressure switch MDR 2/11 w/unloader

5075010

Pressure switch MDR 21/11 UL compl.

5075100

Pressure switch MDR21/11 UL complete w/unloader

5085000

Pressure switch MDR 4S/11 compl.

510000

Gauge リ40 016 bar 1/8” down

5210000

Capacitor start 70uF

520000

Capacitor start 160uF UL

520226

Handle, multi complete

540001

Handle f/615/625 complete

5410000

Oil level glass compl.

5410000

Oil level glass compl.

5412000

Intake filter f/6 motors, complete

5414000

Oil inlet screw w/gasket

5414500

Non return valve

5416000

Safety valve 10 bar / 145 psi

5416200

Safety valve 16 bar / 22 psi

5416200

Safety valve 16 bar / 22 psi

5418000

Drain cock 1/4” 4l

5419500

Drain cock 1/4” 15l

5420000

Drain cock 1/4” 25l

5421001

Drain cock 1/4” 40l (new)

5425000

Distributor f/non return valve compl.

5425000

Distributor f/non return valve compl.

5425500

Safety valve TÜV 10 bar

5426500

Safety valve TÜV 16 bar

5427000

Connecting piece 1/4”

5429000

Adaptor 5way compl.

5429100

Adaptor 4way compl.

5429500

Adaptor 2way compl.

5451400

Fan compl. 120V 120x120mm

5451500

Fan compl. 20V 120x120mm

545000

Fan guard 120x120

5470251

Spare parts kit f/replacement of valve plate f/ motor

(new)

547000

Spare parts kit f/replacement of valve plate f/6 motor

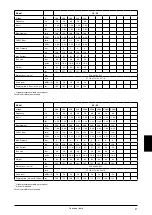

Spare parts

Summary of Contents for 12-25

Page 2: ......

Page 4: ......

Page 32: ......

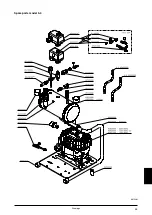

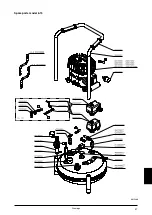

Page 33: ...33 Motor spare parts model 3 Motor spare parts model 3 Drawings 0013101 0013001 Drawings...

Page 34: ...34 Motor spare parts model 6 Motor spare parts model 6 0015100 0015200 Drawings...

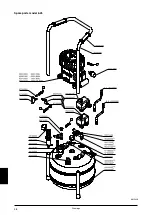

Page 35: ...35 Spare parts model 3 4 0015301 Drawings...

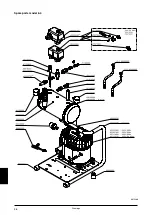

Page 36: ...36 Spare parts model 6 4 0015300 Drawings...

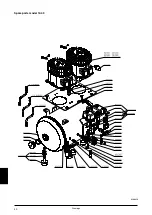

Page 37: ...37 Spare parts model 6 15 0015400 Drawings...

Page 38: ...38 Spare parts model 6 25 0015450 Drawings...

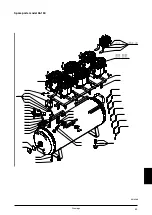

Page 39: ...39 Spare parts model 12 25 0019700 Drawings...

Page 40: ...40 Spare parts model 12 40 0200650 Drawings...

Page 41: ...41 Spare parts model 18 40 0200660 Drawings...

Page 42: ...42 Spare parts model 24 40 0200670 Drawings...

Page 43: ...43 Spare parts model 36 150 0016500 Drawings...

Page 44: ...44 Accessories 0991041 0991040 0015900 Drawings...

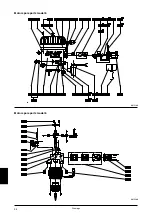

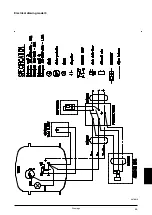

Page 45: ...45 Electrical drawing model 3 6070010 Drawings...

Page 46: ...46 Electrical drawing model 6 6070160 Drawings...

Page 47: ...47 Electrical drawing model 12 6070210 Drawings...

Page 48: ...48 Electrical drawing model 18 6070260 Drawings...

Page 49: ...49 Electrical drawing model 24 400V 50Hz 6070310 Drawings...

Page 50: ...50 Electrical drawing model 24 230V 50 60Hz 6070311 Drawings...

Page 51: ...51 Electrical drawing model 36 400V 50Hz 6070360 Drawings...

Page 52: ...52 Electrical drawing model 36 230V 50Hz 6070361 Drawings...

Page 54: ......

Page 55: ......