Spare parts

490100

Cooling pipe, complete

479000

Phase relay f/1-2000 motors

47900

Contactor Danfoss C9/220V

479405

Thermo relay 1.2-1.9A Danfoss

4740400

Cage clamp connector

4750000

Control lamp 20V

4750010

Control lamp 20V w/spade plug

4750210

Control lamp 120V w/spade plug

4750710

Bracket 10 cm

4750714

Bracket 14 cm

4752000

Hour counter 20V

4752200

Hour counter 120V

4779901

Thermo switch ajustable

4781500

Plug male -pole f/metal cabinet

478800

Switch f/metal cabinet (green)

478901

Switch f/metal cabinet (20A)

478910

Switch x400V f/metal cabinets

4785025

Solenoid valve 200V/50-0Hz

478500

Solenoid valve f/unloader 20V w/plug

478550

Solenoid valve f/unloader 120V w/plug

4799500

Auto drain 220-240V series 590

479900

Auto drain 120V series 590

4799700

Auto drain 20V series 520

4799855

Special auto drain for unloading 20V

5074800

Pressure switch MDR 21/11 4-way UL

5150000

Gauge Ø40 0-1 bar 1/8” built-in

522000

Strap f/capacitor Ø45x40mm

525805

Capacitor, run complete 10uF/20V AC f/OF00

(0 cm)

527505

Capacitor, run complete 25uF/20V AC f/OF00

(5 cm)

52750

Capacitor, run complete 25uF/20V AC f/OF00

(0 cm)

524005

Capacitor, run complete 0uF/120V AC f/OF00

(5 cm)

5412400

Intake filter f/OF01 and OF02 motors

5414500

Non return valve

541100

Safety valve 12 bar / 177 psi

5417000

Safety valve 9 bar / 15 psi

5418000

Drain cock 1/4” 4l

5420000

Drain cock 1/4” 25l

5421001

Drain cock 1/4” 40l (new)

5422702

Drain cock 1/4” 40l f/cabinet

5422800

Draintube f/metal cabinet size C & D

5422801

Draintube f/metal cabinet size B

5422802

Draintube f/metal cabinet size A

5425700

Safety valve TÜV 12.2 bar

542900

Branch pipe 2xOF02M(D)

542902

Branch pipe xOF02M(D)

5447000

Radiator f/radiator & fan box

5450100

Fan 120V 120x120

2881100

Motor compressor OF01 20V/50Hz

2881200

Motor compressor OF01 120V/0Hz

288120

Motor compressor OF01 20V/0Hz

2881400

Motor compressor OF01 100V/50Hz

2881420

Motor compressor OF01 100V/0Hz

2881440

Motor compressor OF01 200V/50Hz

288140

Motor compressor OF01 200V/0Hz

2882200

Motor compressor OF02 120V/0Hz

2882208

Motor compressor OF02 20V/50-0Hz

288200

Motor compressor OF02 100V/50Hz

288220

Motor compressor OF02 100V/0Hz

288240

Motor compressor OF02 200V/0Hz

28820

Motor compressor OF02 200V/0Hz

2882400

Motor compressor OF02 x400V/50-0Hz

050099

Receiver 4l with inspection plug CE, silver,

internally coated

410087

Receiver, 25 l silver w/inspection plug internally

coated for metal cabinet ASME

410097

Receiver 25l with inspection plug f/metal

cabinet, silver

512199

Receiver 40 l for metal cabinet w/inspection

plug silver internally coated CE/ASME

4071010

Filter 5um w/automatic drain, complete

4071020

Regulator R07-280-RNMG, 10 bar

4071290

Panel ring f/regulator and filter regulator

4081100

Camtimer 120V/0Hz for dryer

4081200

Camtimer 20V/50Hz for dryer

4082529

Dryer complete OF01 OX 120V

408250

Dryer complete OF01 OX 20V

408251

Dryer complete OF02 OX 8 Bar

408252

Dryer complete OF02 OX 10 Bar

40855

Dryer complete f/ metal cabinet xOF02 type

OX 8 bar size

4085

Dryer complete f/ metal cabinet xOF02 type

OX 10 bar size

414100

Rapid fitting 1/4” internal mm hose

414101

Rapid fitting 1/4” internal x Ø8 mm

4141700

Rapid fitting 1/4” external x Ø

4141800

Rapid fitting elbow 1/8”xØ

4141820

Rapid fitting elbow 1/8”internal x Ø

414180

Rapid fitting elbow 1/8” int. x Ø8

414500

Rapid fitting elbow 1/8”xØ8

414501

Rapid fitting 1/8” x Ø8

414200

Rapid fitting elbow 1/4”xØ8 KQL08-02S

414201

Rapid fitting 1/4”xØ8

41420

Rapid fitting lead-in 1/4”xØ8mm

414410

Rapid fitting distributor 1/4” xØxØ8

414458

Rapid fitting Ø8mmxØ8mm elbow

414800

Rapid fitting Ømmx1/4” elbow

414802

Rapid fitting lead-in 1/4” x Ø mm

4147000

Rapid fitting 1/8” ext. x Ømm

Spare parts

Summary of Contents for 2 OF302-40M Series

Page 4: ......

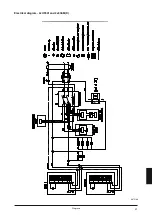

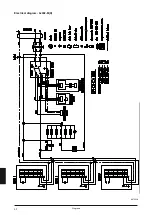

Page 30: ...30 6072960 Electrical diagram OF301 and 302 M D Diagrams...

Page 31: ...31 6073160 Electrical diagram 2xOF301 and 2x302 M D Diagrams...

Page 32: ...32 Electrical diagram 3x302 M D 6073250 Diagrams...

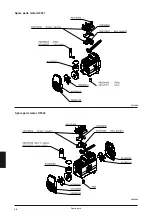

Page 36: ...36 Spare parts motor OF301 0070000 0080000 Spare parts motor OF302 Spare parts...

Page 37: ...37 Spare parts OF301 4M 0080120 Spare parts...

Page 38: ...38 Spare parts OF301 4MD2 0080121 Spare parts...

Page 39: ...39 Spare parts OF302 4M 0080122 Spare parts...

Page 40: ...40 Spare parts OF302 4MD2 0080123 Spare parts...

Page 41: ...41 Spare parts OF302 25M 0080130 Spare parts...

Page 42: ...42 Spare parts OF302 25MD2 0080131 Spare parts...

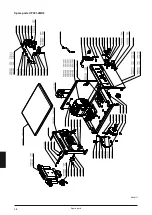

Page 43: ...43 Spare parts 2xOF302 40M 0080140 Spare parts...

Page 44: ...44 Spare parts 2xOF302 40MD2 0080141 Spare parts...

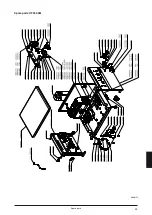

Page 45: ...45 0080150 Spare parts 3xOF302 40M Spare parts...

Page 46: ...46 0080151 Spare parts 3xOF302 40MD3 Spare parts...

Page 47: ......