9

Service

Please note that all service must be carried out by a qualified

person.

Adjustment of pressure switch

The working presure has ben preset from the factory, and it is

normally not necessary to change this.

However, if it is necessary to change the preset settings, the

instructions mentioned below should be followed carefully.

Warning!

The compressor is constructed and approved

for a max. pressure as stated under Technical

Specifications - do not adjust to a higher pressure.

Higher working pressure will reduce the lifetime of

the compressor.

The compressor will stop at max. pressure (stop pressure) and

start again at min. pressure (start pressure). The difference

between max. and min. pressure is the differens pressure.

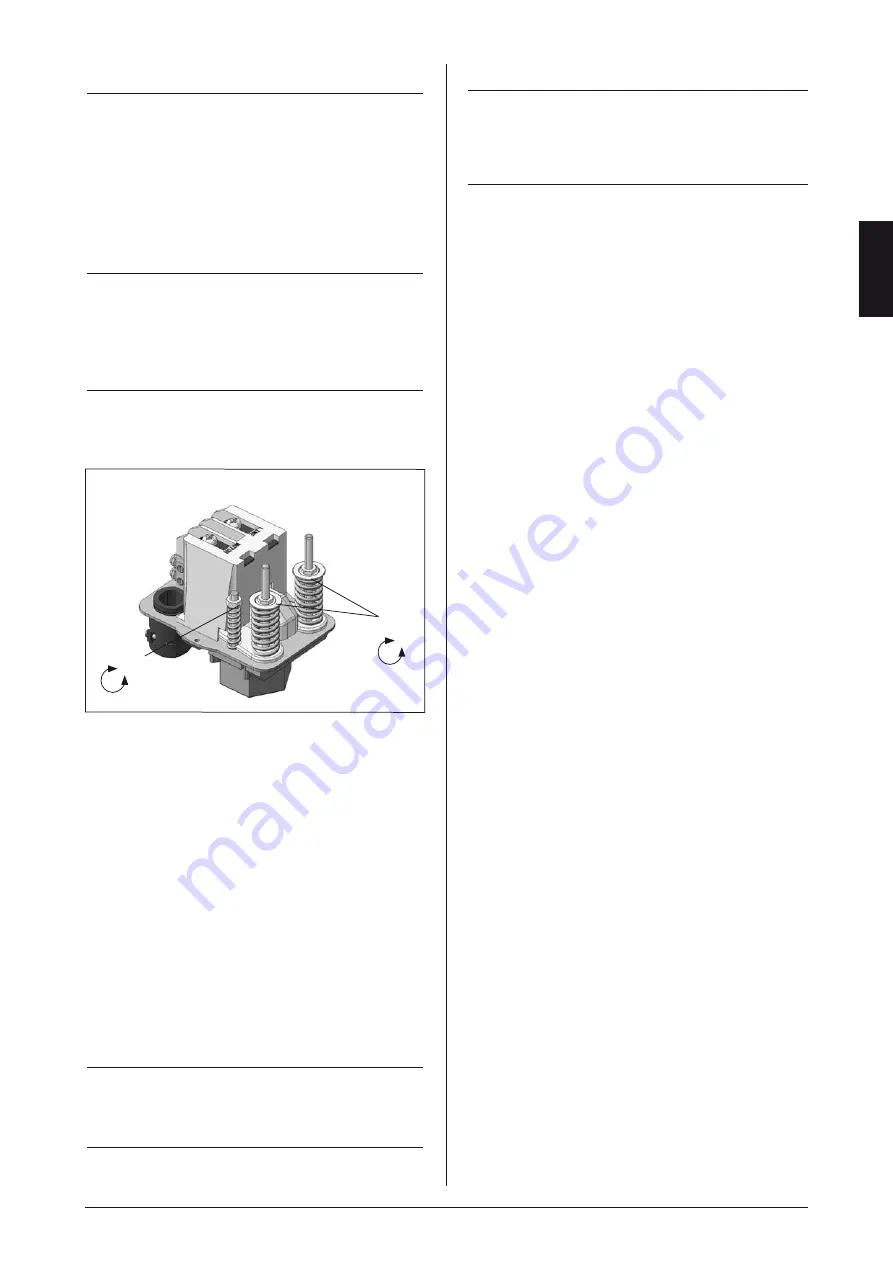

Unscrew the lid of the pressure switch. Adjust max. pressure

adjusting the two springs marked A (clockwise: higher

pressure). Adjust the two springs identically.

Adjust the differens pressure adjusting the spring marked B

(clockwise: higher differens pressure, lower start pressure.

Test of pumping time

The pumping time indicates the condition of the compressor.

Check that there are no leaks in the system.

Empty the air receiver of compressed air so that the

pressure gauge shows 0 bar.

Close the filter regulator and check that the drain valve is

closed.

Start the compressor and note the time it takes until it is

turned off again by the pressure switch. Check that the

pumping time agrees with the technical specifications for

the actual compressor system.

Please note that the pumping time in this manual is given for 0

to max pressure. Deviations from this result in deviating results.

Important!

Always test the pumping time when cold. If the

compressor is warm, the pumping time will be

considerably longer.

1.

2.

.

4.

Fault finding and repair

Important

Switch off and isolate from electrical supply before

removing any parts from the compressor. Empty air

receiver of air before performing any operation on the

compressors' pressure system.

1. Compressor does not start

The air receiver is pressurized. The motor will start when

the pressure has dropped to the preset start pressure.

Empty the receiver.

Check that the mains supply agrees with the motor label.

No power from mains. Check fuses and plug.

Bad connection or broken cable.

The motor is overheated and the thermal protection

has switched it off. When cooled the motor will turn on

automatically. Go to section 5.

The compressor has not been unloaded and there is back

pressure on the piston. Ensure that the compressor is unloaded

each time it stops.

The motor is blocked.

Defective capacitor.

2. The compressor makes a buzzing sound but does not start

Leaky non-return valve. Dismount the pressure pipe and

check if air leaks from the non-return valve. Clean and

replace.

The motor is blocked.

3. The compressor runs but the pressure does not increase

Intake filter clogged. Replace.

Non-return valve is clocked. Clean or replace.

Leaks in fittings, tubes or pneumatic equipment. Check with

soapy water or by letting unit stay over night disconnected

from mains. Pressure drop should not exceed 1 bar.

Check the piston gaskets. Replace if necessary.

Defective valve plate. Contact your JUN-AIR distributor.

5. The motor gets very hot

The ambient temperature is too high. If the motor is installed

in a cabinet sufficient ventilation must be ensured.

Leaks in fittings, tubes or pneumatic equipment. Check with

soapy water or by letting unit stay over night disconnected

from mains. Pressure drop should not exceed 1 bar.

The compressor is overloaded.

6. The compressor runs even if no air is tapped

Leaks in fittings, tubes or pneumatic equipment. Check with

soapy water or by letting unit stay over night disconnected

from mains. Pressure drop should not exceed 1 bar.

7. The compressor does not start at min pressure or does

not stop at max pressure.

Defective pressure switch. Replace.

a.

b.

c.

d.

e.

f.

g.

h.

a.

b.

a.

b.

c.

d.

e.

a.

b.

c.

a.

a.

B

A

+

-

+

-

Operating manual

GB

Summary of Contents for 2 OF302-40M Series

Page 4: ......

Page 30: ...30 6072960 Electrical diagram OF301 and 302 M D Diagrams...

Page 31: ...31 6073160 Electrical diagram 2xOF301 and 2x302 M D Diagrams...

Page 32: ...32 Electrical diagram 3x302 M D 6073250 Diagrams...

Page 36: ...36 Spare parts motor OF301 0070000 0080000 Spare parts motor OF302 Spare parts...

Page 37: ...37 Spare parts OF301 4M 0080120 Spare parts...

Page 38: ...38 Spare parts OF301 4MD2 0080121 Spare parts...

Page 39: ...39 Spare parts OF302 4M 0080122 Spare parts...

Page 40: ...40 Spare parts OF302 4MD2 0080123 Spare parts...

Page 41: ...41 Spare parts OF302 25M 0080130 Spare parts...

Page 42: ...42 Spare parts OF302 25MD2 0080131 Spare parts...

Page 43: ...43 Spare parts 2xOF302 40M 0080140 Spare parts...

Page 44: ...44 Spare parts 2xOF302 40MD2 0080141 Spare parts...

Page 45: ...45 0080150 Spare parts 3xOF302 40M Spare parts...

Page 46: ...46 0080151 Spare parts 3xOF302 40MD3 Spare parts...

Page 47: ......