6189902 – Rev. C 07.2012

4

GB

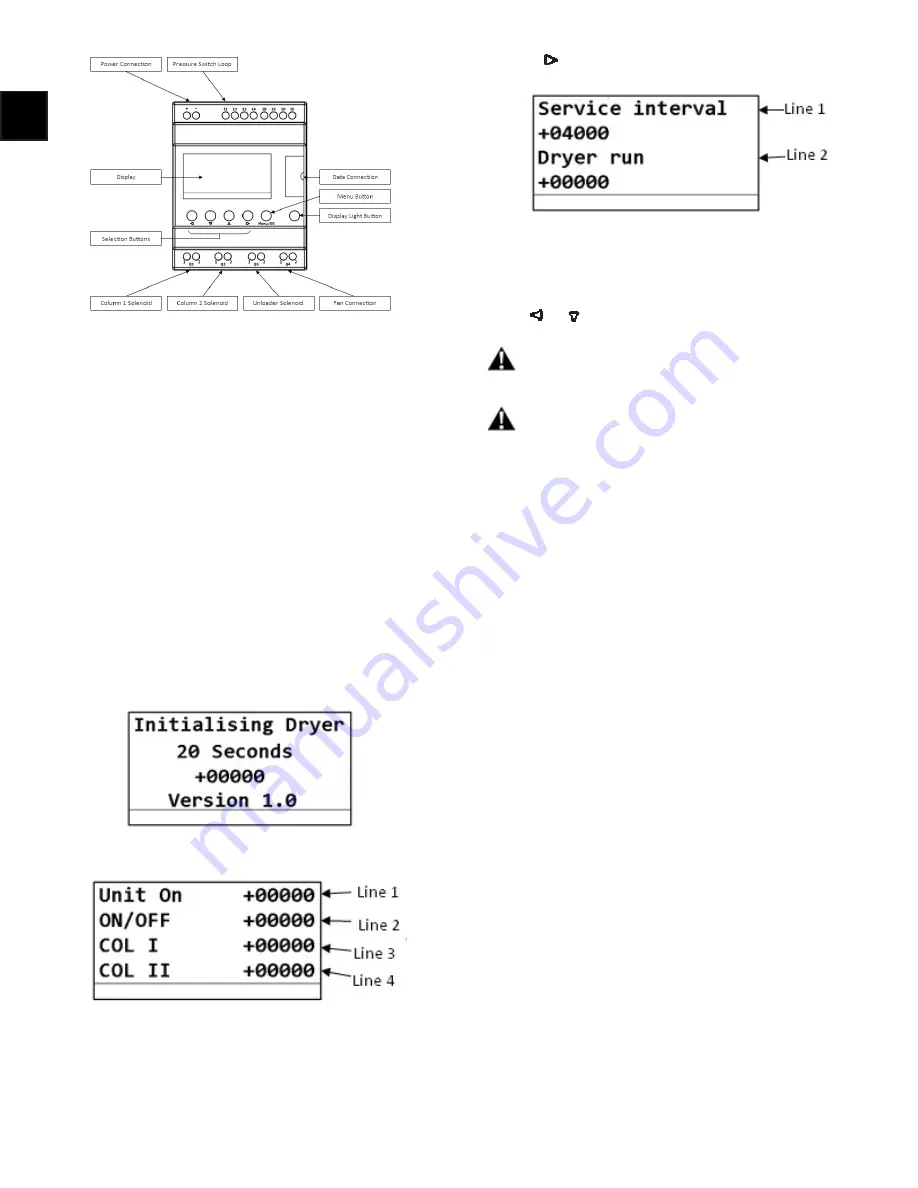

Figure 2

Power Connection:

Supplies input power to the PLC from the

pressure switch.

Pressure Switch Loop:

Input control to notify PLC of compressor

operation status.

Display:

Displays current status and menu options.

Selection Buttons:

Navigate menu or display service interval.

Column 1 Solenoid:

Connection for the first dryer solenoid.

Column 2 Solenoid:

Connection for the second dryer solenoid.

Un-loader Solenoid:

Connection for pressure relief solenoid

(Note: Only utilized on Cabinet versions).

Fan Connection:

Connection for system cooling fan

(Note: Only utilized on Cabinet versions).

Display Light Button:

The white button on the right of the PLC will

illuminate the display.

Menu Button:

Used only for factory setting of the PLC.

Data Connection:

Used only for factory setting of the PLC.

Start up:

When the system is connected to power, the PLC will enter a 20

second initialization to ensure that the dryer is functional and ready to

operate. The PLC will count down from 20 seconds.

When the PLC finishes initialization, it will display the Home screen

shown below.

Line 1:

Number of total run hours accumulated.

Line 2:

Number of total system cycles accumulated.

Line 3:

Number of cycles on dryer column #1.

Line 4:

Number of cycles on dryer column #2.

Note:

New systems will be shipped with several cycles on each of the

columns. This is because the unit is tested before it leaves the factory.

When the

selection button is pressed, the PLC will display the

recommended service interval and total system run hours accumulated:

Line 1:

Recommended service interval.

Line 2:

Number of total run hours accumulated

When replacement service is carried out on the dryer, the dryer

run counter (Line 2) can be reset by depressing the first 2 selection

buttons

and

on the PLC at the same time. This must be done

for 15 seconds to reset the dryer run time counter.

WARNING: Reconfiguring the factory settings on the PLC is

not recommended. This will result in the dryer not functioning

properly and void the warranty.

ADDITIONAL WARNINGS:

Unless the directions below are followed and authorized JUN-AIR

parts are used, physical injury or property damage may result.

The following additional warnings must be noted;

•

The dryer is only suitable for installations with nominal voltages

equal to that stated on the dryer rating label.

•

The dryer is designed to operate at pressures between 4 barg

and 12 barg. It is not suitable for pressures in excess of 12 barg.

•

Only connect pneumatic equipment suitable for the maximum

pressure indicated.

•

The dryer is designed to operate with inlet temperatures

between 0 and 50°C (32°F and 122°F).

•

Product servicing should only be carried out by authorized JUN-

AIR distributors.

•

The dryer should be protected against rain, moisture, frost and

dust.

•

Contact between the dryer and any chemicals, solvents or

paints must be avoided.

•

Ensure system is switched off and disconnected from power and

the system fully depressurized before attempting to access the

serviceable components of the dryer.

•

Only 3/8 BSPP fittings should be used. Use of any other fittings

will result in damage to the pressure vessel components.

•

The dryer exhaust ports cannot be fitted with any silencing

devices. The exhaust fluids must be expelled into the drain

bottle supplied by JUN-AIR through the tubing provided. The

performance of the dryer will be reduced if the exhaust ports

are restricted.

Technical Specifications:

Quality classes according to ISO 8573-1: 2001 of Class 2: Dirt: 1 μm/

Class 2: Water: -40°C (-40°F) PDP

Minimum working pressure:

4 barg (58 psig)

Maximum working pressure:

12 barg(174 psig)

Nominal Power supply:

24V DC/ 110 VAC/ 230 VAC

Minimum air temperature:

0°C (32°F)

Maximum air temperature:

50°C (122°F)

Min. Ambient temperature:

-10°C (14°F)

Max. Ambient Temperature:

40°C (104°F)